# What Is Supply Chain Intelligence? The Ultimate Guide to Data-Driven Visibility

Imagine you are the captain of a massive container ship. You have a destination, but the ocean is vast. You need to know about weather patterns, other ship traffic, port congestion, and the health of your own vessel. Without this constant stream of information, you are sailing blind. This is the modern supply chain without intelligence. So, what is supply chain intelligence? At its core, it is the systematic process of collecting, analyzing, and applying data from across your supply network to gain actionable insights, predict disruptions, and make smarter, faster decisions. It transforms raw data into a strategic asset.

This guide will break down this complex concept. We will explore its components, benefits, and how you can start building a more intelligent supply chain today.

UNDERSTANDING THE CORE COMPONENTS

Supply chain intelligence is not a single software tool. It is a capability built on several interconnected layers. Think of it as a pyramid. The base is data. The middle is technology. The peak is insight and action.

First, you need data aggregation. This involves pulling information from every possible source: your ERP and Warehouse Management Systems, IoT sensors on trucks and shelves, GPS trackers, supplier portals, social media feeds, and even global news for geopolitical events. The goal is to create a single, unified view.

Next comes advanced analytics and artificial intelligence. This is where raw data becomes useful. Predictive analytics can forecast demand spikes or delays. Prescriptive analytics can suggest the best alternate shipping route. Machine learning models continuously improve these predictions by learning from new data.

Finally, the intelligence must be presented through visualization and reporting tools. Dashboards show key performance indicators in real-time. Alert systems notify managers of exceptions, like a shipment running late. This enables proactive management instead of reactive firefighting.

THE CRITICAL BENEFITS OF IMPLEMENTING INTELLIGENCE

Why should companies invest in building this capability? The benefits directly impact the bottom line and competitive advantage.

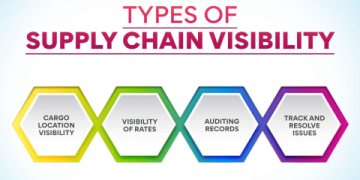

Enhanced visibility is the most immediate gain. You move from knowing what is in your four walls to seeing the entire journey of a product, from raw material to the customer’s door. This transparency builds trust with partners and customers.

Risk mitigation becomes proactive. For example, by monitoring weather patterns and port data, an intelligent system can flag a potential hurricane disruption weeks in advance, allowing you to reroute shipments. According to a report by Resilinc, supply chain disruptions cost companies an average of 10-15% of their annual EBITDA (来源: Resilinc EventWatch Report).

Operational efficiency skyrockets. With better demand forecasting, you can optimize inventory levels, reducing carrying costs and minimizing stockouts. A study by McKinsey found that companies using advanced supply chain analytics improve their logistics costs by 15%, inventory levels by 35%, and service levels by 65% compared to slower-moving competitors (来源: McKinsey & Company).

SUPPLY CHAIN INTELLIGENCE VS. TRADICAL SUPPLY CHAIN MANAGEMENT

It is easy to confuse basic supply chain management with an intelligent one. The difference is profound. The table below highlights the key distinctions.

| Aspect | Traditional Supply Chain Management | Intelligent Supply Chain |

|---|---|---|

| Data Use | Relies on historical, internal data (ERP). Reactive reporting. | Integrates real-time internal and external data. Predictive and prescriptive analytics. |

| Decision-Making | Manual, based on experience and siloed information. Slow. | Data-driven, often automated or AI-assisted. Rapid and proactive. |

| Visibility | Limited to immediate suppliers and customers. Opaque. | End-to-end, multi-tier visibility. Transparent. |

| Risk Response | Reactive. Responds to disruptions after they occur. | Proactive. Anticipates and mitigates risks before they impact operations. |

| Technology Core | ERP, basic planning tools. | Cloud platforms, IoT, AI/ML, advanced analytics. |

As you can see, supply chain intelligence represents a fundamental shift from a linear, reactive process to a dynamic, networked, and cognitive one.

A 5-STEP GUIDE TO BUILDING YOUR SUPPLY CHAIN INTELLIGENCE

Starting this journey can feel overwhelming. Based on my experience consulting with mid-sized manufacturers, breaking it into phases is key. Here is a practical, step-by-step guide.

STEP 1: DEFINE YOUR BUSINESS OBJECTIVES.

Do not start with technology. Start with your business pain points. Is your goal to reduce inventory costs by 20%? Improve on-time delivery to 98%? Mitigate the impact of port delays? Clear objectives will guide every subsequent decision and help you measure success.

STEP 2: AUDIT YOUR DATA LANDSCAPE.

Identify what data you already have and where it lives. Talk to teams in procurement, logistics, sales, and manufacturing. Also, identify critical external data sources you lack, such as supplier performance data or regional risk indicators. This audit reveals your data gaps and quality issues.

STEP 3: SELECT AND INTEGrate TECHNOLOGY.

You do not need to build everything from scratch. Evaluate platforms like Blue Yonder, E2open, or Microsoft Dynamics 365 Supply Chain Center. The right platform should be able to connect to your existing systems (ERP, WMS) and aggregate diverse data streams into a single source of truth.

STEP 4: DEVELOP ANALYTICS AND ALERTS.

Begin with foundational descriptive analytics (What happened?). Then, build towards predictive models (What will happen?). Start small—for instance, create a model to predict late shipments from specific lanes. Set up automated alerts for key exceptions, like inventory falling below a critical threshold.

STEP 5: FOSTER A DATA-DRIVEN CULTURE.

Technology is useless without people. Train your teams to use the new dashboards and trust the data. Encourage them to make decisions based on insights, not just gut feeling. We have seen teams resist new systems simply because they were not involved in the process or trained properly.

COMMON PITFALLS AND WARNINGS

WARNING: DO NOT TREAT THIS AS A PURELY IT PROJECT.

The biggest mistake is delegating supply chain intelligence entirely to the IT department. This is a business transformation initiative that requires strong leadership from operations, logistics, and executive sponsors. IT enables the solution, but the business defines the problem.

Another major pitfall is pursuing perfection in data. You will never have 100% clean, complete data. Start with the most critical 80% that drives your key objectives. Iterate and improve data quality over time. Waiting for perfect data means you will never start.

Finally, avoid vendor hype. Ensure any technology solution you choose can actually integrate with your legacy systems and scale with your needs. Demand clear proof of concepts and talk to existing customers in your industry.

YOUR SUPPLY CHAIN INTELLIGENCE CHECKLIST

Before you launch your initiative, use this checklist to ensure you are on the right path.

IDENTIFY AND DOCUMENT THREE KEY BUSINESS PAINS YOU WANT TO SOLVE.

ASSIGN A CROSS-FUNCTIONAL PROJECT TEAM WITH CLEAR LEADERSHIP.

INVENTORY YOUR INTERNAL DATA SOURCES AND QUALITY.

PRIORITIZE TWO CRITICAL EXTERNAL DATA SOURCES TO INTEGRATE.

SELECT A PILOT AREA, SUCH AS MONITORING A HIGH-RISK SHIPPING LANE.

DEFINE METRICS TO MEASURE THE PILOT’S SUCCESS.

BUDGET FOR ONGOING TRAINING AND CHANGE MANAGEMENT.

PLAN FOR ITERATIVE EXPANSION AFTER THE PILOT.

In conclusion, understanding what is supply chain intelligence is the first step toward building a resilient, efficient, and competitive operation. It is no longer a luxury for giant corporations. It is a necessity for any business that wants to survive and thrive in an unpredictable world. By turning data into foresight, you stop being a captain sailing blind and start navigating with confidence.