# The Ultimate Supply Chain Blueprint: A 7-Step Guide to Build Resilience and Efficiency

A supply chain blueprint is not just a diagram. It is the foundational master plan for how your business sources, makes, and delivers value. In a world of constant disruption, from geopolitical shifts to climate events, operating without a clear blueprint is like sailing a stormy sea without a map. This guide provides the definitive framework to design, implement, and optimize your supply chain blueprint for lasting competitive advantage.

We will move beyond theory into actionable strategy. You will learn the core components, see a direct comparison of planning methodologies, and follow a step-by-step construction guide. By the end, you will have a clear path to transform your supply chain from a cost center into a strategic asset.

UNDERSTANDING THE SUPPLY CHAIN BLUEPINT CORE

At its heart, a supply chain blueprint is a living document that visualizes and codifies your end-to-end operational flow. It maps every touchpoint from raw material supplier to end customer. Crucially, it also defines the policies, performance metrics, and technology stack that govern that flow.

Think of it as the architectural plan for a building. The blueprint shows the structure (suppliers, factories, warehouses), the systems (plumbing, electrical, which equate to software and data flows), and the safety features (compliance, risk mitigation). Without it, construction is chaotic, costly, and prone to collapse.

KEY ELEMENTS EVERY BLUEPRINT MUST CONTAIN

A comprehensive supply chain blueprint addresses four interconnected layers:

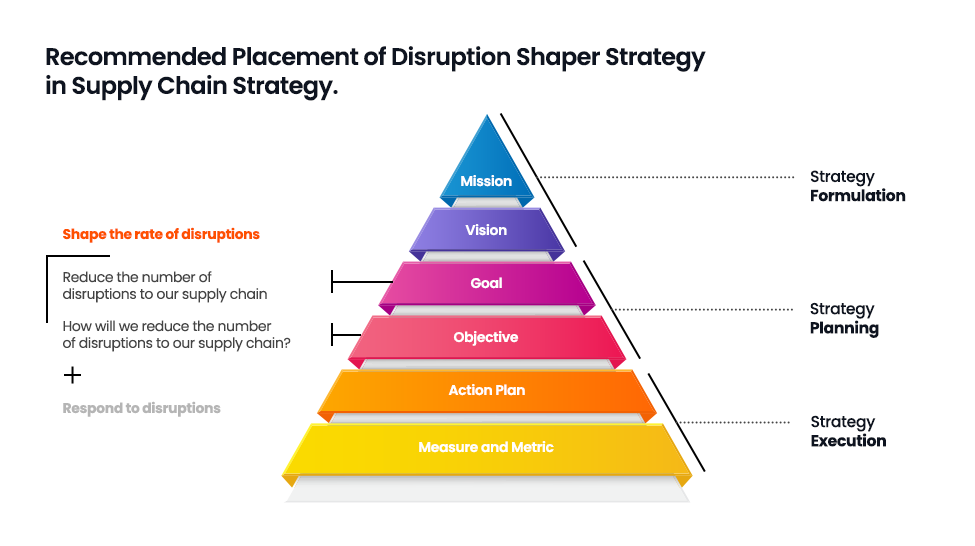

1. STRATEGIC ALIGNMENT: This ties the supply chain directly to business goals. Is the aim lowest cost, maximum speed, or superior flexibility? Your blueprint must reflect this primary objective.

2. NETWORK DESIGN: This is the physical and logistical map. It answers where to place factories, distribution centers, and how to route products. Advanced modeling here can reduce logistics costs by 10-15% (来源: Council of Supply Chain Management Professionals).

3. PROCESS STANDARDIZATION: Here, you document the exact steps for procurement, production, demand planning, and fulfillment. Consistency here eliminates waste and errors.

4. TECHNOLOGY AND DATA ENABLERS: This specifies the software (like ERP, TMS, WMS) and the key performance indicators (KPIs) that will provide visibility and control.

COMMON MISSTEP: A frequent mistake is diving straight into technology selection without defining the first three layers. You end up automating broken processes, simply making bad decisions faster. Your blueprint must follow a logical sequence: Strategy -> Network -> Process -> Technology.

COMPARING BLUEPRINT APPROACHES: LEAN VS. AGILE

Not all supply chain blueprints look the same. The optimal design depends heavily on your product type and market demand. Here is a clear comparison of two dominant models:

| Feature | Lean Supply Chain Blueprint | Agile Supply Chain Blueprint |

|---|---|---|

| PRIMARY GOAL | Minimize cost and eliminate waste. | Maximize responsiveness to volatile demand. |

| BEST SUITED FOR | High-volume, predictable, commodity products. | Innovative, fashion, or high-margin products with uncertain demand. |

| INVENTORY STRATEGY | Minimize inventory across the chain (Just-in-Time). | Strategically buffer key components or finished goods. |

| SUPPLIER RELATIONSHIPS | Long-term, collaborative, cost-focused. | Flexible, multi-sourced, capability-focused. |

| KEY METRIC | Cost per unit, Asset utilization. | Speed to market, Perfect order fulfillment. |

In practice, many leading companies develop a hybrid blueprint. They apply lean principles to their stable product lines and agile principles to their innovative, fast-moving segments. This segmented approach is often the hallmark of a mature supply chain blueprint.

THE 7-STEP PROCESS TO BUILD YOUR SUPPLY CHAIN BLUEPRINT

Follow this actionable guide to construct your blueprint from the ground up.

STEP 1: CONDUCT A CURRENT-STATE DIAGNOSIS.

You cannot plan where you are going without knowing your starting point. Map your existing supply chain in detail. Identify all partners, processes, costs, and pain points. Collect data on lead times, inventory levels, and service performance.

STEP 2: DEFINE FUTURE BUSINESS OBJECTIVES.

Align with executive leadership on 3-5 year business goals. Are you entering new markets? Launching new product categories? This step ensures your supply chain blueprint supports growth, rather than constraining it.

STEP 3: MODEL AND DESIGN THE FUTURE NETWORK.

Use network design software or consultants to simulate different scenarios. Ask: What if we add a regional warehouse? What if a key supplier fails? This step optimizes the physical footprint for both cost and resilience. According to a McKinsey study, companies that digitally model their supply networks can improve service levels by up to 5% while reducing costs (来源: McKinsey & Company).

STEP 4: DOCUMENT CORE PROCESSES AND POLICIES.

Formalize how every critical operation should run. This includes sourcing strategies, inventory management policies (like Min/Max levels), and order fulfillment rules. This documentation becomes your operational bible.

STEP 5: SELECT THE TECHNOLOGY STACK.

Now, choose the systems that will execute and monitor your blueprint. Key platforms include an ERP (central hub), a planning tool, and execution systems for warehousing and transportation. Prioritize solutions that offer real-time visibility and analytics.

STEP 6: DEVELOP A RISK MANAGEMENT AND RESPONSE PLAN.

Integrate risk assessment directly into your blueprint. Identify single points of failure—be it a sole-source supplier or a single port of entry. For each high-risk node, define a mitigation action, such as qualifying a backup supplier or holding safety stock.

STEP 7: CREATE A PHASED IMPLEMENTATION ROADMAP.

A blueprint is useless if not implemented. Break the transformation into manageable phases with clear milestones, owners, and success metrics. A typical roadmap might start with process standardization before rolling out new technology.

From my experience consulting with mid-sized manufacturers, the most successful implementations are those where the supply chain blueprint is treated as a change management project, not just a technical one. Engaging teams from procurement, logistics, and sales early in the process builds crucial buy-in and surfaces practical insights that pure data analysis might miss.

IMPLEMENTATION CHECKLIST FOR YOUR SUPPLY CHAIN BLUEPRINT

Before you launch your transformation, use this final checklist to ensure your supply chain blueprint is robust and actionable.

– Business goals are clearly defined and translated into supply chain objectives.

– A complete map of the current as-is supply chain is completed and validated.

– Future network design has been modeled against at least three scenarios (cost-optimized, resilient, balanced).

– All core operational processes are documented with clear owners and handoff points.

– Key technology platforms are selected based on their ability to enable the blueprint, not just replace old systems.

– A risk register is created with mitigation plans for the top five identified vulnerabilities.

– A communication and training plan is in place for all affected employees and partners.

– A 12-18 month implementation roadmap with quarterly review gates is established and approved.

By methodically working through this guide, you move from having a reactive supply chain to owning a proactive, strategic supply chain blueprint. This document becomes your single source of truth, guiding daily decisions and long-term investments. It turns complexity into clarity and vulnerability into a verifiable competitive edge. Start your mapping today—the resilience you build will define your success tomorrow.