# The Ultimate Guide to Titanium Price Per Ounce in 2024: What Drives the Cost?

If you are researching the titanium price per ounce, you have likely discovered it is not a straightforward number like gold or silver. Titanium pricing is a complex world influenced by industrial demand, production costs, and material form. This guide will break down everything you need to know, from the raw sponge to the finished aerospace component, giving you a clear picture of what drives the cost of this remarkable metal.

Understanding the titanium price per ounce requires looking beyond a simple spot price. We will explore the different forms of titanium, the key market drivers, and provide you with practical tools for making informed decisions, whether you are an investor, engineer, or curious enthusiast.

## What is the Current Price of Titanium Per Ounce?

As of early 2024, there is no single, universally traded spot price for titanium metal in the way there is for precious metals. The cost is highly dependent on the form and purity of the material. However, we can provide a realistic range based on commercial-grade material.

Commercially pure titanium (Grade 2) in common forms like sheet or bar typically ranges from $0.50 to $2.50 per ounce. This translates to roughly $8 to $40 per pound. For comparison, an ounce of silver trades around $25, while an ounce of gold is over $2,000. So, while titanium is a premium industrial metal, its price per ounce by weight is relatively low. The high value comes from its performance and the cost of processing it into usable forms.

It is crucial to note that these figures are for the raw metal. The price per ounce for a finished titanium product, such as a medical implant or a jet engine blade, can be orders of magnitude higher due to the extensive machining, testing, and certification required.

## Key Factors That Influence Titanium Pricing

Several interconnected factors determine the final titanium price per ounce you will pay. Here are the primary drivers:

PRODUCTION COST: The Kroll process, the dominant method for extracting titanium from ore, is energy-intensive and complex. This foundational cost sets a floor for pricing. Fluctuations in electricity and magnesium (a key reagent) prices directly impact the cost of titanium sponge, the raw metallic form.

INDUSTRIAL DEMAND: Titanium is a bellwether for high-tech manufacturing. Demand from the aerospace and defense sectors is the single largest driver. When airplane production ramps up, so does the price of titanium. Similarly, growth in medical, chemical processing, and luxury consumer goods creates competing demand.

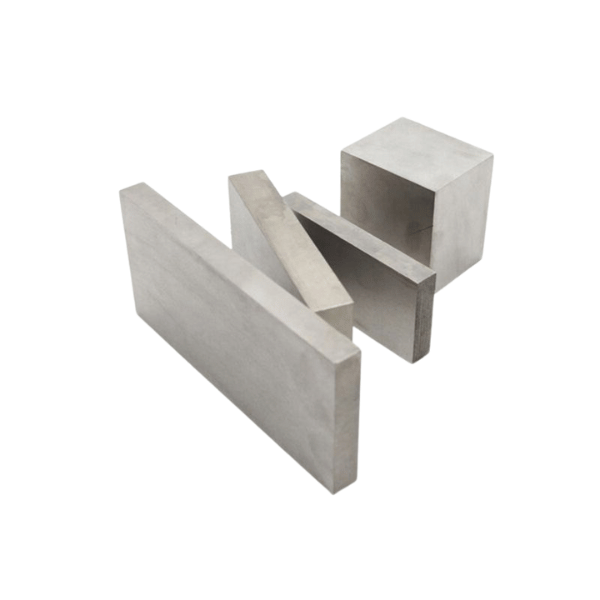

MATERIAL FORM AND GRADE: The cost varies dramatically by product form. Sponge is the cheapest form per ounce. Mill products like sheet, plate, bar, and wire cost more. Further processed forms like tubing or fasteners command a higher price. Alloys like Ti-6Al-4V (Grade 5) are more expensive than commercially pure grades.

GLOBAL SUPPLY CHAIN: The titanium market is geographically concentrated. Major sponge producers are in China, Japan, Kazakhstan, and Russia. Trade policies, tariffs, and geopolitical events can disrupt supply and cause price volatility. For instance, recent geopolitical tensions have led to increased scrutiny and diversification of supply chains, affecting costs. (来源: US Geological Survey Mineral Commodity Summaries)

## Titanium vs. Other Metals: A Price and Property Comparison

To understand titanium’s value proposition, it is not just about the price per ounce. Its superior strength-to-weight ratio and corrosion resistance make it cost-effective for critical applications where other metals would fail. The following table compares key metrics.

| Metal | Approx. Price Per Ounce (Raw Material) | Density | Key Advantage | Common Use Case |

|---|---|---|---|---|

| Titanium (Grade 2) | $0.50 – $2.50 | 4.51 g/cm³ | Strength-to-Weight, Corrosion Resistance | Aerospace frames, chemical plants |

| Aluminum 6061 | $0.10 – $0.20 | 2.70 g/cm³ | Light Weight, Low Cost | Consumer electronics, automotive parts |

| Stainless Steel 304 | $0.15 – $0.30 | 8.00 g/cm³ | High Strength, Low Cost | Construction, food processing |

| Inconel 718 | $5.00 – $8.00 | 8.19 g/cm³ | High-Temperature Strength | Jet engine turbines |

As you can see, titanium’s price per ounce sits between common structural metals and high-performance superalloys. Its unique combination of properties justifies its cost in demanding environments.

## How to Get an Accurate Titanium Quote: A 5-Step Guide

Getting a meaningful price for your specific need requires more than searching “titanium price per ounce.” Follow this practical guide.

STEP 1: DEFINE YOUR SPECIFICATIONS. You must know the exact alloy grade (e.g., Grade 2, Grade 5, Ti-6Al-4V), the product form (sheet, rod, tube, wire), and the dimensions (thickness, diameter, length).

STEP 2: DETERMINE THE QUANTITY. Pricing differs vastly between a one-off piece for a prototype and a bulk order for production. Have your estimated annual usage or project quantity ready.

STEP 3: IDENTIFY SUPPLIER TYPES. Distributors stock standard shapes and offer convenience. Mills produce the raw forms and handle large orders. Job shops specialize in fabrication. Choose based on your needs.

STEP 4: PREPARE FOR CERTIFICATIONS. For critical applications, you will need mill test reports (MTRs) that certify the chemical and mechanical properties of the material. This is standard for aerospace (AMS specs) and medical (ASTM F136) uses and adds to the cost.

STEP 5: REQUEST FORMAL QUOTES. Contact multiple suppliers with your complete specification package. The quote will typically be per piece or per pound, not per ounce. Always clarify if cutting, machining, or additional testing is included.

## Common Misconceptions and Pitfalls to Avoid

When evaluating the titanium price per ounce, several misconceptions can lead to poor decisions.

A MAJOR PITFALL is assuming all titanium is the same. The difference between Grade 2 and Grade 5 titanium is like the difference between mild steel and tool steel. Using the wrong grade can lead to catastrophic failure. Another common error is focusing solely on the material cost per ounce. For machined parts, the cost of machining titanium—which is difficult and time-consuming—can be 5 to 10 times the cost of the raw material. Ignoring logistics and supplier reliability for a slightly lower price can result in project delays that are far more costly. Always consider total landed cost and supply chain security.

## The Future Outlook for Titanium Costs

Looking ahead, several trends will influence the titanium price per ounce. The aerospace industry’s recovery and next-generation programs like more fuel-efficient jets will sustain strong demand. The additive manufacturing (3D printing) revolution is creating new demand for high-quality titanium powder, which commands a significant premium over sponge. On the supply side, new production technologies, like electrochemical processes aiming to replace the Kroll process, promise lower energy use and cost. If commercialized, they could disrupt the market. However, adoption will take time. According to a market analysis by Grand View Research, the global titanium market size is expected to grow significantly this decade, driven by these advanced applications, which will keep upward pressure on prices. (来源: Grand View Research)

In my experience consulting with manufacturers, we have seen that building a long-term relationship with a reputable supplier is often more valuable than chasing the absolute lowest price per ounce. This ensures consistent quality, reliable lead times, and technical support.

## Your Titanium Procurement Checklist

Use this actionable checklist before your next purchase to ensure you get the right material at a fair price.

– Clearly define the required titanium alloy grade and specification standard.

– Have detailed drawings or specifications for form, size, and tolerance.

– Determine the necessary material certifications (MTR, AMS, ASTM).

– Calculate both your immediate quantity and potential annual usage.

– Research and identify potential distributors, mills, or fabricators.

– Request formal quotes from at least three suppliers with full specs.

– Compare total cost, including any processing, testing, and shipping.

– Verify supplier lead times and reliability, not just price.

– Consider the long-term partnership value for future projects.

– Finalize the order with all specifications and certifications in writing.

By understanding the multifaceted drivers behind the titanium price per ounce, you are now equipped to navigate this specialized market with confidence. Remember, the true cost of titanium is measured not just in dollars per ounce, but in the unparalleled performance and reliability it delivers where it matters most.