# The Ultimate Guide to the Evolution of Supply Chain Management: From Silos to Synergy

Understanding the evolution of supply chain management is not just an academic exercise. It is the key to unlocking resilience, efficiency, and competitive advantage in today’s volatile world. This journey from simple logistics to a complex, integrated ecosystem mirrors the broader story of global commerce itself. In this comprehensive guide, we will trace this critical evolution, examine its current state, and provide a practical roadmap for the future.

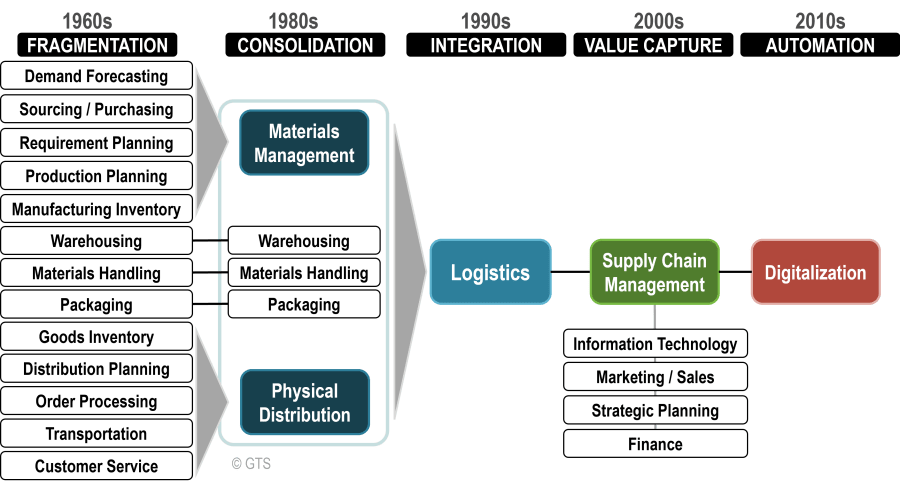

The core theme here is integration. The story of supply chain evolution is one of breaking down barriers between departments, companies, and continents. We have moved from managing isolated functions to orchestrating dynamic networks. This shift was driven by necessity, as globalization, technological leaps, and rising customer expectations forced a complete rethink.

## The Foundational Era: Physical Distribution and Logistics

In the early to mid-20th century, supply chain activities were fragmented and uncoordinated. Manufacturing, warehousing, and transportation were managed as separate silos, often with conflicting goals. The primary focus was on the physical movement of goods—a concept known as physical distribution management. Efficiency was measured in cost per mile or warehouse throughput, with little regard for how one function impacted another. Inventory was often used as a buffer against uncertainty, leading to high carrying costs and frequent stockouts. This disjointed approach was the starting point for the evolution of supply chain management.

## The Integration Revolution: From Logistics to Supply Chain

A major leap in the evolution of supply chain management occurred in the 1980s and 1990s with the introduction of the integrated supply chain concept. Thinkers and practitioners began to see the value in connecting internal functions like procurement, production, and distribution. The goal shifted from minimizing local costs to optimizing the total system. This era was fueled by two key enablers: the rise of Enterprise Resource Planning (ERP) systems, which created a single source of truth across the organization, and the adoption of Just-In-Time (JIT) principles, which emphasized waste reduction and flow. For the first time, companies could see how a delay in procurement rippled through to a missed customer delivery.

## The Digital and Global Leap: Technology as the Great Connector

The turn of the millennium accelerated the evolution of supply chain management at a breathtaking pace. The internet and globalization transformed linear chains into complex, global networks. Key developments included:

– E-commerce, which created demand for direct-to-consumer logistics and perfect order fulfillment.

– Advanced planning software (APS) for better forecasting and scheduling.

– The proliferation of RFID and early IoT sensors, providing better visibility into asset location.

However, this complexity also introduced new vulnerabilities. Extended networks became more exposed to disruptions, as evidenced by the 2011 Fukushima disaster, which halted automotive production worldwide. A study by the Business Continuity Institute found that 85% of organizations reported at least one supply chain disruption in 2023, with cyber-attacks and logistics delays being top causes (来源: BCI Supply Chain Resilience Report 2023). This highlighted a critical weakness: visibility was still often limited to a company’s immediate tier-one suppliers.

## The Modern Era: Intelligence, Resilience, and Circularity

Today, we are in the era of the digital, resilient, and sustainable supply chain. The evolution of supply chain management is now defined by intelligence and adaptability. Modern supply chains are built on a digital twin—a virtual model that simulates the physical network. Artificial Intelligence and Machine Learning crunch vast datasets for predictive analytics, forecasting demand spikes or predicting machine failures before they happen. Blockchain is emerging for provenance and secure documentation.

Furthermore, resilience has moved from an afterthought to a core design principle. The COVID-19 pandemic was a brutal teacher, proving that efficiency alone is fragile. Companies are now building redundancy, diversifying suppliers, and nearshoring critical operations. Sustainability is equally paramount, driving the transition toward circular supply chains that design out waste and prioritize reuse.

Here is a comparison of the key philosophies driving this modern evolution:

| Aspect | Traditional Lean Supply Chain (Past Focus) | Modern Resilient Supply Chain (Current Imperative) |

|---|---|---|

| PRIMARY GOAL | Cost Efficiency & Optimization | Agility, Responsiveness & Risk Mitigation |

| INVENTORY STRATEGY | Minimize, JIT | Strategic Buffer Stock, Multi-Sourcing |

| NETWORK STRUCTURE | Lean, Globalized for Cost | Diversified, Regionalized/Nearshored |

| TECHNOLOGY DRIVER | ERP, Basic Automation | AI, IoT, Cloud, Digital Twin |

| SUPPLIER RELATIONSHIPS | Transactional, Cost-Driven | Collaborative, Partnership-Driven |

## A 5-Step Guide to Modernizing Your Supply Chain

Based on my experience consulting with mid-sized manufacturers, a successful modernization journey follows a clear, phased approach. You cannot jump straight to AI without the foundational pieces in place.

STEP 1: CONDUCT A RESILIENCE AUDIT. Map your entire end-to-end network, identifying single points of failure, critical dependencies, and high-risk nodes. Assess both upstream (supplier) and downstream (logistics) vulnerabilities.

STEP 2: INVEST IN CORE VISIBILITY. Before you can predict, you must see. Implement integrated tracking (IoT sensors, GPS) and a cloud-based platform that provides real-time data on inventory in transit, at warehouses, and at production sites. This is the non-negotiable foundation.

STEP 3: DATA CLEANSING AND INTEGRATION. Garbage in, garbage out. Dedicate time to cleaning your master data on products, suppliers, and customers. Ensure your CRM, ERP, and WMS systems can communicate seamlessly via APIs.

STEP 4: PILOT AN ADVANCED ANALYTICS PROJECT. Start small. Choose one high-impact use case, such as predictive maintenance for key machinery or AI-driven demand forecasting for your top 10% of SKUs. Measure the ROI rigorously.

STEP 5: FOSTER A CULTURE OF COLLABORATION. Technology is only an enabler. Break down internal silos between procurement, logistics, and sales. Externally, develop strategic partnerships with key suppliers for joint planning and transparency.

WARNING: A COMMON MODERNIZATION PITFALL

A major mistake we see is companies chasing the latest technology buzzword without a clear problem to solve. Do not buy a blockchain solution looking for a problem. Instead, start with a painful, expensive, or risky problem in your current evolution of supply chain management—like counterfeit parts or complex compliance documentation—and then evaluate if blockchain is the right tool. Technology must serve strategy, not the other way around.

## The Future Trajectory: Autonomous and Predictive Networks

The next phase in the evolution of supply chain management is autonomy. We are moving toward self-correcting, self-optimizing networks. Imagine a system where an AI not only predicts a port delay but automatically reroutes shipments, adjusts production schedules, and notifies customers—all without human intervention. The integration of AI, robotics, and IoT will make this a reality. Furthermore, sustainability will be baked into the algorithm, with systems automatically selecting the lowest-carbon shipping option or optimizing for circular product returns.

The journey of the supply chain is a continuous one, from fragmented operations to interconnected, intelligent ecosystems. By understanding this evolution, businesses can better navigate the present and strategically invest for the future. The goal is no longer just to move goods efficiently, but to create adaptive, transparent, and responsible value networks.

CHECKLIST FOR ASSESSING YOUR SUPPLY CHAIN EVOLUTION:

– We have mapped our end-to-end supply network beyond tier-one suppliers.

– We have real-time visibility into inventory across all major nodes and in-transit.

– Our data from different systems (ERP, WMS, TMS) is integrated and reliable.

– We have formally assessed and documented our key supply chain risks.

– We utilize predictive analytics for at least one core function (e.g., demand, maintenance).

– We have diversified sources for critical materials or components.

– Our sustainability metrics (carbon, waste) are tracked and integrated into decision-making.

– Our internal teams (procurement, logistics, sales) collaborate on a shared platform.

– We conduct joint business planning with key strategic suppliers.

– Our technology roadmap is driven by specific business problems, not just trends.