# The Ultimate Guide to the Customer Supply Chain: 5 Steps to Unlock Growth and Loyalty

For decades, supply chain management focused on one thing: efficiency. The goal was to move products from raw materials to the end consumer as quickly and cheaply as possible. But a profound shift is underway. Today, the most successful companies are not just managing a supply chain; they are orchestrating a CUSTOMER SUPPLY CHAIN.

This is more than semantics. A traditional supply chain is linear and product-centric. The CUSTOMER SUPPLY CHAIN is dynamic and customer-centric. It flips the model, starting with the customer’s needs and desires and working backward to design every process—from demand sensing and inventory placement to last-mile delivery and returns—around delivering an exceptional experience.

Q: Why does this matter now? Because customers are in control. They expect perfect product availability, fast and free shipping, transparent tracking, and effortless returns. A study by PwC found that 32% of customers would stop doing business with a brand they loved after just one bad experience. Your supply chain is no longer a back-office function; it is your primary customer-facing engine.

## What is a Customer Supply Chain? The Core Philosophy

At its heart, the CUSTOMER SUPPLY CHAIN is a strategic framework. It integrates customer data, feedback, and behavior directly into supply chain planning and execution. The objective shifts from cost minimization to value maximization, where value is defined by the customer.

This involves key concepts like demand sensing, which uses real-time data (social media trends, weather, local events) to predict what customers will want, not just what they bought last quarter. It encompasses agile logistics networks that can fulfill orders from stores, warehouses, or third-party partners based on what is fastest for that specific customer. Ultimately, it creates a responsive, resilient, and transparent flow of goods and information.

## The Pillars of a Modern Customer-Centric Supply Chain

Building this requires strengthening four foundational pillars.

VISIBILITY is the non-negotiable first step. You cannot optimize what you cannot see. End-to-end visibility means tracking inventory, orders, and shipments in real-time across all channels and partners. This allows you to provide accurate delivery promises and proactive alerts.

FLEXIBILITY in logistics and fulfillment is critical. Can you ship from store? Can you offer buy-online-pickup-in-store (BOPIS) or curbside pickup? A flexible network reduces shipping costs and speeds up delivery. According to a McKinsey report, companies with highly flexible supply chains grew revenue 20% faster than their peers.

INTEGRATION of systems is the technical backbone. Your CRM, order management system, warehouse management system, and transportation management system must share data seamlessly. Siloed data creates blind spots and poor decisions.

ANALYTICS AND AI transform data into action. Predictive analytics forecast demand more accurately. Machine learning can optimize delivery routes and inventory allocation down to the store shelf level. This moves the supply chain from reactive to proactive.

## Technology Showdown: Enabling the Customer-Centric Shift

The right technology stack is the enabler of the CUSTOMER SUPPLY CHAIN. Here is a comparison of two critical platform categories.

| Feature / Aspect | Traditional ERP with SCM Modules | Modern, Cloud-Native Supply Chain Platform |

|---|---|---|

| Core Architecture | Monolithic, on-premise or hosted. Modules are tightly coupled. | Microservices-based, API-first, and cloud-native. Highly modular. |

| Data & Analytics | Relies on historical data for planning. Batch processing leads to latency. | Real-time data ingestion and processing. Built-in AI/ML for predictive insights. |

| Flexibility & Scalability | Difficult and expensive to modify. Scaling requires hardware. | Highly configurable. Scales elastically with cloud resources. |

| Integration Approach | Complex, point-to-point integrations. Often creates data silos. | API-driven ecosystem. Designed for easy connection with best-of-breed tools (CRM, WMS, TMS). |

| Total Cost of Ownership (TCO) | High upfront license and implementation costs. Significant IT overhead. | Subscription-based (SaaS). Lower upfront cost, with ongoing operational expense. |

The choice is not always either/or. Many large enterprises run a core ERP for financials while leveraging modern platforms for customer-facing supply chain agility.

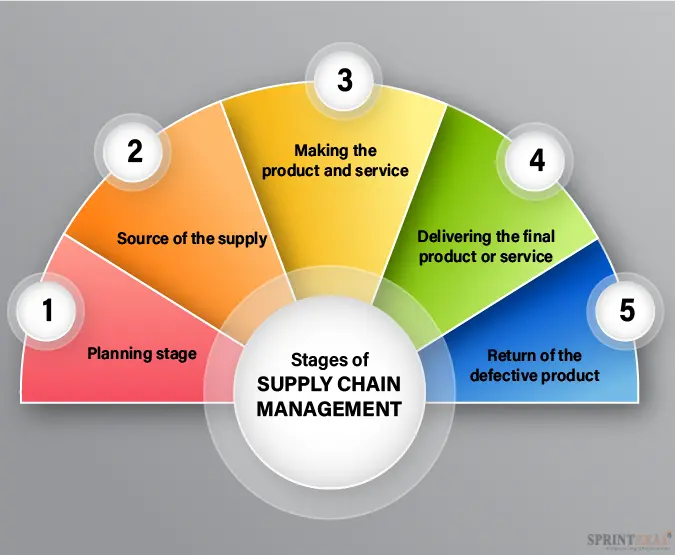

## A 5-Step Blueprint to Build Your Customer Supply Chain

Transformation can feel daunting. Based on my experience working with retail and manufacturing teams, breaking it down into phases is key. Here is a practical, five-step blueprint you can follow.

STEP 1: MAP THE CUSTOMER JOURNEY AND PAIN POINTS.

Start not with your warehouses, but with your customers. Document every touchpoint they have with your physical and digital supply chain: browsing online for stock, checking delivery options at checkout, receiving tracking updates, the unboxing experience, and the returns process. Identify where frustrations occur—long delivery times, stockouts, poor communication.

STEP 2: AUDIT YOUR CURRENT CAPABILITIES AGAINST THE PILLARS.

Conduct an honest assessment of your four pillars: Visibility, Flexibility, Integration, and Analytics. Can you see inventory across all channels in real-time? How many fulfillment options do you offer? How well do your systems talk to each other? This gap analysis becomes your roadmap.

STEP 3: PRIORITIZE QUICK WINS AND LAUNCH A PILOT.

Do not try to boil the ocean. Choose one high-impact, achievable project. For example, implement a system to provide proactive SMS/email alerts for delivery delays. Or, pilot a ship-from-store program in your top three metro areas. Demonstrate value quickly to secure buy-in for larger initiatives.

STEP 4: INVEST IN THE UNIFYING TECHNOLOGY LAYER.

This is often a cloud-based Order Management System (OMS) or a supply chain control tower. This platform becomes the “brain,” connecting all your channels, inventory pools, and carriers. It makes the complex decisions—like where to fulfill an order from—to meet customer promises at the lowest cost.

STEP 5: INSTITUTE A CULTURE OF CONTINUOUS FEEDBACK LOOP.

Embed customer feedback directly into supply chain planning. Regularly review customer service logs, product return reasons, and delivery satisfaction scores. Use this qualitative data to refine your processes, inventory planning, and carrier partnerships. The CUSTOMER SUPPLY CHAIN is never “finished”; it evolves with your customers.

## Common Pitfalls and How to Avoid Them

WARNING: A successful CUSTOMER SUPPLY CHAIN initiative can be derailed by classic mistakes.

A major pitfall is treating this as a purely IT project. The technology is crucial, but without aligned goals across merchandising, marketing, store operations, and logistics, it will fail. Leadership must champion this as a cross-functional business strategy.

Another common error is focusing only on the “last mile” of delivery. While delivery is critical, a broken link upstream—like a supplier delay or a forecasting error—dooms the final experience. You must improve visibility and collaboration across the entire network, including your suppliers.

Finally, do not neglect the returns process. A difficult returns experience can erase all the goodwill from a perfect purchase. Make returns easy, free, and fast. Consider a “return in store for instant credit” option or pre-printed return labels. Your reverse logistics strategy is a core part of the customer experience.

## The Future is Demand-Driven

The evolution from a traditional supply chain to a true CUSTOMER SUPPLY CHAIN is the defining competitive edge in modern commerce. It turns logistical operations into a powerful engine for customer satisfaction, loyalty, and repeat purchases. By putting the customer at the center of every decision, you build not just resilience, but a genuine brand advantage that is incredibly hard to replicate.

It requires investment, focus, and cultural change. But the reward is a business that moves in lockstep with its market, anticipates needs, and delivers not just products, but promises. That is the ultimate goal.

CHECKLIST FOR IMPLEMENTING A CUSTOMER SUPPLY CHAIN:

– Map the complete customer order and post-purchase journey.

– Conduct a capability audit across visibility, flexibility, integration, and analytics.

– Form a cross-functional team with leaders from supply chain, IT, marketing, and sales.

– Identify and launch one pilot project for a quick win.

– Select and implement a central orchestration platform (e.g., OMS).

– Design a transparent and easy returns process.

– Establish a regular review of customer feedback with the supply chain team.

– Develop KPIs focused on customer experience (e.g., Perfect Order Rate, On-Time Delivery, Returns Satisfaction).