# The Ultimate Guide to Supply Chain Policy: A 7-Step Framework for Resilience and Compliance

A supply chain policy is no longer a nice-to-have document. It is the foundational blueprint for how your company manages risk, ensures ethical operations, and builds a competitive advantage. In a world of constant disruption, from geopolitical tensions to climate events, a well-crafted policy moves from the back office to the boardroom agenda. This guide provides a deep dive into what a modern supply chain policy entails and gives you a practical framework to build or overhaul your own.

Think of your supply chain policy as the constitution for your entire network of suppliers, logistics, and processes. It sets the non-negotiable rules and aspirational goals. Without it, decisions become reactive, inconsistent, and risky. A startling 73% of supply chain professionals report that their organizations experienced at least one significant disruption in the past year, highlighting the acute need for structured governance (来源: [Resilinc 2023 Annual Report]).

## What is a Supply Chain Policy? Beyond the Definition

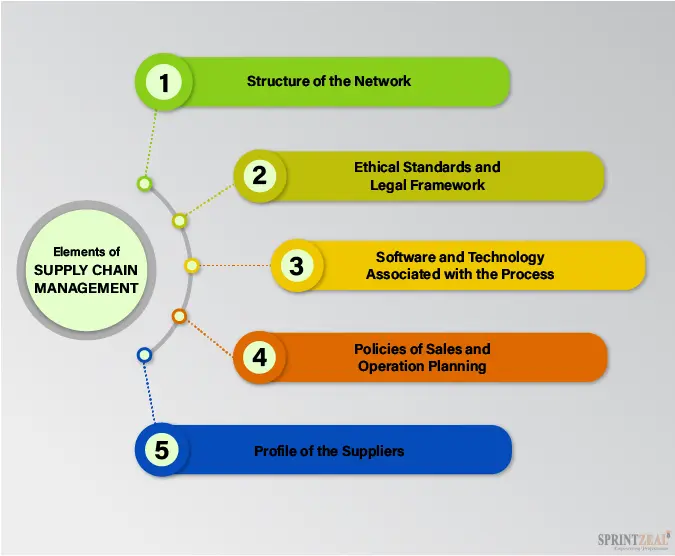

At its core, a supply chain policy is a formal document that outlines the principles, standards, and procedures a company requires across its end-to-end supply chain. It goes far beyond basic procurement rules. A modern policy integrates several critical dimensions:

ETHICAL SOURCING AND LABOR STANDARDS: This mandates compliance with laws against forced labor, ensures safe working conditions, and guarantees fair wages. It is your first line of defense against reputational damage.

ENVIRONMENTAL AND SUSTAINABILITY COMMITMENTS: This section addresses carbon footprint reduction, waste management, circular economy principles, and sustainable sourcing of raw materials.

RISK MANAGEMENT AND RESILIENCE: This defines how to identify, assess, and mitigate risks, whether they are geopolitical, financial, operational, or related to force majeure.

QUALITY AND COMPLIANCE REQUIREMENTS: It sets the technical and regulatory standards that all supplied goods and services must meet, ensuring consistency and safety.

DATA SECURITY AND TECHNOLOGY USE: In an interconnected world, this governs how data is shared with partners and what cybersecurity standards must be upheld.

## Why Your Current Approach Might Be Failing: The Policy Gap

Many companies operate with fragmented guidelines or a policy that is purely ceremonial, gathering dust in a digital folder. The common pitfalls include:

POLICIES THAT ARE TOO VAGUE: Statements like “we value sustainability” are meaningless without specific, measurable targets.

SILOED CREATION: When the procurement team writes the policy in isolation, it misses critical input from legal, compliance, sustainability, and operations teams.

NO TEETH OR ENFORCEMENT: A policy without clear accountability, audit rights, and consequences for non-compliance is merely a suggestion.

STATIC DOCUMENTS: The global landscape changes monthly. A policy not reviewed at least annually is quickly obsolete.

From my experience consulting with mid-sized manufacturers, the most common point of failure is the assumption that once a supplier signs a contract, they are automatically aligned with the company’s policy. In reality, without ongoing communication, training, and verification, this alignment is superficial at best.

## Core Components of a World-Class Supply Chain Policy

A robust policy document should be clear, accessible, and actionable. Its structure typically includes:

1. PURPOSE AND SCOPE: A clear statement of why the policy exists and who it applies to (e.g., all tier-1 suppliers, and where possible, tier-2).

2. GOVERNANCE AND OWNERSHIP: Defining who is responsible for maintaining, updating, and enforcing the policy.

3. PRINCIPLES AND STANDARDS: The detailed expectations across the five dimensions mentioned earlier (ethics, environment, risk, quality, data).

4. SUPPLIER SELECTION AND ONBOARDING: The process for evaluating new suppliers against the policy criteria.

5. MONITORING AND AUDITING: The methods for ongoing compliance verification, including self-assessments, audits, and certifications.

6. REMEDIATION AND CONTINUOUS IMPROVEMENT: The process for addressing violations and a commitment to regularly raising standards.

7. COMMUNICATION AND TRAINING: How the policy will be communicated internally and to the supply chain.

## Supply Chain Policy vs. Supplier Code of Conduct: A Critical Distinction

These terms are often used interchangeably, but they serve distinct, complementary purposes. Understanding the difference is key to effective implementation.

| Aspect | Supply Chain Policy | Supplier Code of Conduct |

|---|---|---|

| PRIMARY AUDIENCE | Internal stakeholders (employees, management, board) | External stakeholders (suppliers, vendors, partners) |

| NATURE | Internal governance document, sets strategic direction and internal rules. | External-facing contractual document, communicates non-negotiable requirements. |

| SCOPE | Broader. Includes internal processes, risk management frameworks, data governance, and overall supply chain strategy. | Narrower. Focuses specifically on the ethical, social, and environmental standards expected of suppliers. |

| LEGAL STATUS | An internal policy, often referenced in contracts. | Typically incorporated into supply contracts, making it legally binding. |

In short, your supply chain policy informs how you build your supplier code of conduct. The policy is your internal playbook; the code of conduct is the rulebook you give to your team and your partners.

## The 7-Step Framework to Develop Your Supply Chain Policy

Follow this actionable guide to create a policy that is both strategic and practical.

STEP 1: ASSEMBLE A CROSS-FUNCTIONAL TEAM. This cannot be owned by one department. Include leaders from Procurement, Legal, Compliance, Sustainability, Risk Management, Operations, and Finance.

STEP 2: CONDUCT A MATERIALITY ASSESSMENT. Identify the most significant social, environmental, and economic impacts of your supply chain. What are your biggest risks and opportunities? Use frameworks from the Sustainability Accounting Standards Board (SASB) or consult stakeholder feedback.

STEP 3: BENCHMARK AND ANALYZE REGULATIONS. Research not just current laws (like the U.S. Uyghur Forced Labor Prevention Act or the EU’s Corporate Sustainability Due Diligence Directive) but also emerging regulations in your key markets. Proactive compliance is a competitive moat.

STEP 4: DRAFT THE POLICY DOCUMENT. Using the core components listed earlier as a template, draft the policy. Be specific. Instead of “reduce emissions,” state “require all tier-1 suppliers to measure and report Scope 1 and 2 emissions by 2025.”

STEP 5: INTEGRATE WITH EXISTING PROCESSES. The policy must be embedded into real workflows. Update your supplier onboarding checklist, RFQ templates, and contract clauses to include policy requirements.

STEP 6: DEVELOP COMMUNICATION AND TRAINING PLANS. Create different versions of the policy: a detailed internal document, a summarized version for suppliers, and training modules for your procurement team.

STEP 7: ESTABLISH A REVIEW CYCLE. Formalize an annual review process to update the policy based on performance data, new risks, and evolving standards.

## Common Pitfalls and How to Avoid Them

WARNING: DO NOT TREAT THIS AS A BOX-TICKING EXERCISE. The greatest risk is creating a beautiful policy that has no connection to daily operations. If your procurement team’s incentives are still based solely on cost reduction, they will bypass a policy that prioritizes sustainable but slightly more expensive suppliers.

Another major mistake is failing to support your suppliers, especially smaller ones, in meeting your standards. Expecting immediate compliance with complex reporting without offering guidance or reasonable timelines sets everyone up for failure. A collaborative approach, where you work with strategic suppliers to improve, yields far better long-term results than a punitive one.

## Your Supply Chain Policy Implementation Checklist

Use this actionable list to track your progress. A comprehensive supply chain management strategy is built on these pillars.

CROSS-FUNCTIONAL POLICY DEVELOPMENT TEAM HAS BEEN FORMED AND CHARTERED.

MATERIALITY ASSESSMENT HAS BEEN COMPLETED TO IDENTIFY TOP RISKS AND OPPORTUNITIES.

CURRENT AND FORTHCOMING REGULATIONS HAVE BEEN MAPPED AGAINST OUR SUPPLY CHAIN.

POLICY DOCUMENT IS DRAFTED WITH SPECIFIC, MEASURABLE, AND TIME-BOUND COMMITMENTS.

SUPPLIER CODE OF CONDUCT HAS BEEN UPDATED TO ALIGN WITH THE NEW POLICY.

PROCUREMENT PROCESSES (ONBOARDING, CONTRACTS, EVALUATION) HAVE BEEN INTEGRATED.

INTERNAL AND EXTERNAL COMMUNICATION AND TRAINING PLANS ARE IN PLACE.

KEY PERFORMANCE INDICATORS (E.G., SUPPLIER COMPLIANCE RATE, RISK ASSESSMENTS COMPLETED) HAVE BEEN DEFINED.

AN ANNUAL REVIEW AND UPDATE PROCESS HAS BEEN FORMALIZED.

EXECUTIVE SPONSORSHIP AND OVERSIGHT FROM THE BOARD OR SENIOR MANAGEMENT IS SECURED.

Building a future-proof supply chain starts with a strong, living policy. It is the strategic lens through which every sourcing decision, partnership, and innovation should be viewed. By taking a structured, inclusive, and proactive approach, you transform your supply chain from a cost center into a demonstrable source of resilience, ethics, and value. The journey requires commitment, but as global disruptions continue to make headlines, the return on that investment has never been clearer.