A supply chain assessment is not a luxury. It is a fundamental requirement for survival and growth in today’s volatile world. Think of it as a comprehensive health check for the lifeblood of your business. Without it, you are navigating blind, vulnerable to disruptions that can halt operations overnight.

This guide provides a deep, actionable framework for conducting a supply chain assessment. We move beyond theory into practical steps you can implement immediately.

WHAT IS A SUPPLY CHAIN ASSESSMENT?

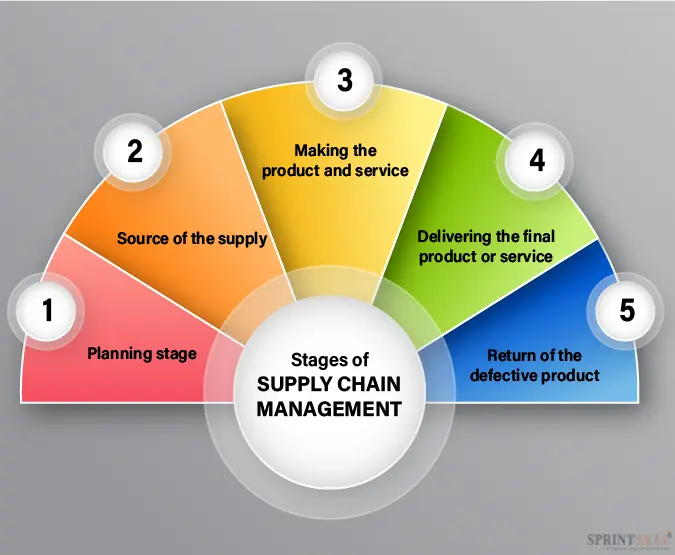

A supply chain assessment is a systematic evaluation of all processes, partners, technologies, and risks involved in moving a product from raw material to the end customer. Its goal is to identify weaknesses, uncover opportunities for efficiency, and build a resilient, agile network. It answers critical questions: Where are we vulnerable? Are we efficient? Can we withstand a shock?

KEY DRIVERS FOR CONDUCTING AN ASSESSMENT

Several forces make a regular supply chain diagnostic essential. Global disruptions, from pandemics to geopolitical tensions, have exposed critical fragilities. Consumer demand for faster, transparent, and sustainable delivery is skyrocketing. Furthermore, advancing technologies like AI and IoT create both competitive pressure and tools for improvement. A 2023 report by Gartner found that 60% of supply chain leaders list building resilience as a top three priority, up from just 21% in 2020 (来源: Gartner).

THE 7-STEP SUPPLY CHAIN ASSESSMENT FRAMEWORK

Follow this structured approach to ensure no critical component is overlooked.

STEP 1: DEFINE SCOPE AND OBJECTIVES

Begin by clarifying what you aim to achieve. Are you assessing the entire global network or a specific product line? Objectives might include reducing costs by 10%, cutting lead times by 15%, or qualifying a list of backup suppliers. Clear goals keep the assessment focused and measurable.

STEP 2: MAP YOUR END-TO-END PROCESS

You cannot improve what you do not see. Create a visual map of your entire supply chain flow. Include every touchpoint: suppliers, manufacturing, logistics, warehouses, and distribution channels. This map reveals complexity and hidden dependencies.

STEP 3: GATHER AND ANALYZE DATA

This is the core of your assessment. Collect quantitative and qualitative data across key performance indicators (KPIs). Critical areas include:

– Supplier Performance: On-time delivery rates, quality metrics, financial health.

– Logistics: Transportation costs, lead times, carrier reliability.

– Inventory: Turnover rates, days of stock on hand, obsolescence levels.

– Demand Planning: Forecast accuracy, order fulfillment cycle time.

STEP 4: IDENTIFY AND PRIORITIZE RISKS

Conduct a thorough risk analysis. Categorize risks as operational, financial, strategic, or compliance-related. Use a risk matrix to plot the likelihood and potential impact of each event. This allows you to prioritize mitigation efforts on high-probability, high-impact threats.

STEP 5: BENCHMARK AND EVALUATE TECHNOLOGY

Compare your performance against industry benchmarks. More importantly, assess your technology stack. Are you relying on spreadsheets and legacy systems, or do you have integrated platforms providing real-time visibility? Technology evaluation is a cornerstone of a modern supply chain assessment.

STEP 6: DEVELOP ACTIONABLE INSIGHTS AND ROADMAP

Translate findings into a clear plan. For each weakness or opportunity, define a specific action, assign an owner, set a timeline, and estimate required resources. This roadmap becomes your strategic playbook.

STEP 7: IMPLEMENT, MONITOR, AND ITERATE

An assessment is pointless without action. Begin executing the roadmap. Crucially, establish a system for continuous monitoring. A supply chain is dynamic; your assessment process should be too. Schedule regular reviews, perhaps quarterly or biannually.

COMMON PITFALLS TO AVOID

WARNING: Many assessments fail to deliver value due to avoidable mistakes. Do not make these errors.

– SCOPE CREEP: Trying to assess everything at once leads to paralysis. Start with a focused scope.

– DATA SILOS: Relying on fragmented data from different departments provides an incomplete picture. Strive for a single source of truth.

– IGNORING SUPPLIER RISK: Assessing only your internal operations is a grave mistake. Your network is only as strong as its weakest link.

– NO FOLLOW-THROUGH: Treating the assessment as a one-time report that sits on a shelf. The real work begins after the analysis.

TOOLS AND SOFTWARE COMPARISON

Choosing the right tool can streamline your supply chain assessment. Here is a comparison of two common approaches:

| Feature / Aspect | Specialized Supply Chain Risk Platforms (e.g., Resilinc, RiskMethods) | Integrated ERP Modules (e.g., SAP IBP, Oracle SCM) |

|---|---|---|

| PRIMARY FOCUS | Deep, external risk intelligence and supplier mapping. | End-to-end internal process integration and planning. |

| RISK DATA SOURCES | Global news, geopolitical feeds, supplier financials, event monitoring. | Primarily internal transactional and operational data. |

| VISIBILITY | Excellent for multi-tier supplier network visibility. | Strong for internal visibility, limited beyond Tier 1 suppliers. |

| IMPLEMENTATION | Faster, often cloud-based. | Complex, lengthy, part of a larger system rollout. |

| BEST FOR | Organizations needing deep risk mitigation and supplier resilience. | Organizations seeking to unify planning and execution data. |

A PRACTICAL EXAMPLE

Consider a mid-sized electronics manufacturer experiencing frequent delays. Their supply chain assessment, following the 7-step framework, revealed a critical dependency on a single supplier for a specialized capacitor. The risk was rated high. The action plan included qualifying two alternative suppliers in different regions and increasing safety stock for that component. Within six months, when a natural disaster hit the primary supplier’s region, production continued uninterrupted using the backup source. This is the power of a proactive assessment.

FROM THE FIELD

In my experience consulting with manufacturing clients, the most overlooked step is often Step 1: defining clear objectives. Teams jump into data collection without alignment, leading to conflicting priorities and wasted effort. We always insist on a formal kickoff workshop to get all stakeholders on the same page. This simple step doubles the effectiveness of the entire assessment.

THE CONTINUOUS IMPROVEMENT CYCLE

A supply chain assessment is not a project with an end date. It is the initiation of a continuous improvement cycle. The insights feed into strategic planning, budgeting, and technology investments. Regular reassessments ensure your supply chain evolves with market demands. According to a McKinsey analysis, companies with highly resilient supply chains can expect earnings growth 3 to 5 percentage points higher than their less-resilient peers during disruptions (来源: McKinsey & Company).

YOUR SUPPLY CHAIN ASSESSMENT CHECKLIST

Use this list to ensure you have covered all bases in your next assessment.

– DEFINE clear, measurable objectives and project scope.

– MAP the physical, informational, and financial flows end-to-end.

– COLLECT data on supplier performance, logistics, inventory, and demand.

– IDENTIFY risks using a likelihood/impact matrix for prioritization.

– EVALUATE current technology capabilities and gaps.

– DEVELOP a detailed action roadmap with owners and deadlines.

– IMPLEMENT changes and establish a schedule for continuous review.

– ENGAGE cross-functional stakeholders from procurement, logistics, and sales.

– COMMUNICATE findings and progress to leadership regularly.

– BUDGET for both the assessment process and the resulting improvement initiatives.

Start your assessment today. The insights you gain will not only protect your business from the next crisis but will unlock efficiencies that drive profitability and competitive advantage for years to come.