# The Ultimate Guide to Retail Supply Chain Risk: Strategies, Solutions, and a 5-Step Action Plan

Modern retail is a high-stakes game of precision and prediction. At its core lies the retail supply chain, a complex network that, when disrupted, can halt operations, erode profits, and damage brand reputation overnight. Understanding and mitigating retail supply chain risk is no longer a back-office function. It is a critical strategic imperative for survival and growth. This guide provides a comprehensive, actionable framework for navigating this complex landscape.

We will move beyond basic definitions to explore the evolving nature of these threats, provide a clear comparison of mitigation strategies, and deliver a concrete action plan you can implement immediately.

## Understanding the Modern Landscape of Retail Supply Chain Risk

Retail supply chain risk refers to the potential for disruptions, failures, or vulnerabilities within the network of suppliers, manufacturers, logistics providers, and distribution channels that deliver products to the end consumer. These are not just theoretical concerns. A 2023 report by the Business Continuity Institute found that 73% of organizations experienced at least one significant supply chain disruption in the previous year. (来源: Business Continuity Institute)

The nature of these risks has evolved. They are no longer just about a truck breaking down. Today, they are multifaceted, interconnected, and often global in scale. A political decision in one continent, a cyber-attack on a software provider, or a sudden shift in consumer demand can ripple through the entire system with astonishing speed.

## The Five Primary Categories of Retail Supply Chain Disruption

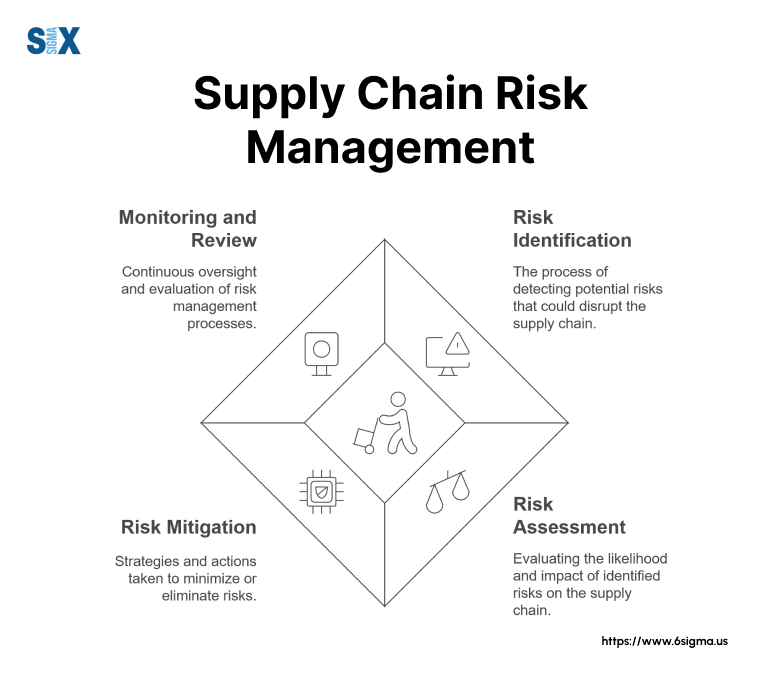

To manage retail supply chain risk effectively, you must first categorize it. Breaking down the threat landscape makes it manageable. We can group the primary risks into five key areas.

OPERATIONAL RISKS: These are internal or day-to-day failures. Think machinery breakdowns, warehouse fires, IT system outages, or critical human error. While often localized, they can cause significant delays and cost overruns.

FINANCIAL RISKS: This category involves the economic stability of your partners. A key supplier going bankrupt, sudden currency fluctuations, or unexpected cost inflation in raw materials can derail your financial planning and product pricing.

DEMAND RISKS: Arising from inaccurate forecasting, these risks lead to the classic retail problems of overstock or stockouts. A failed product launch, a viral social media trend you missed, or a competitor’s surprise promotion can all create dangerous demand volatility.

SUPPLY RISKS: These are failures within your supplier network. They include production delays, quality control failures, raw material shortages, or a supplier’s inability to scale with your growth. Over-reliance on a single source is a major amplifier of supply risk.

EXTERNAL/ENVIRONMENTAL RISKS: This is the broadest and often most unpredictable category. It encompasses natural disasters like hurricanes and floods, geopolitical events like trade wars or port strikes, widespread cyber-attacks, and even pandemics. These events expose the fragility of long, lean, globalized supply chains.

## A Strategic Comparison: Reactive vs. Proactive Risk Mitigation

Not all approaches to managing retail supply chain risk are created equal. The table below contrasts the traditional reactive posture with a modern, proactive strategy. Shifting from the left column to the right is the essence of building true resilience.

| ASPECT | REACTIVE STRATEGY (Traditional) | PROACTIVE STRATEGY (Resilient) |

|---|---|---|

| MINDSET | Respond to disruptions after they occur. | Anticipate and design systems to absorb shocks. |

| INVENTORY POLICY | Lean, Just-in-Time (JIT) to minimize holding costs. | Strategic buffer stock for critical items; diversified JIT. |

| SUPPLIER RELATIONSHIPS | Transactional, based primarily on cost. | Collaborative partnerships with shared data and contingency plans. |

| VISIBILITY | Limited, often siloed data; manual tracking. | End-to-end digital visibility using IoT, AI, and blockchain. |

| INVESTMENT FOCUS | Cost-cutting and efficiency above all. | Balancing efficiency with resilience; investing in agility. |

## The 5-Step Action Plan to Fortify Your Retail Supply Chain

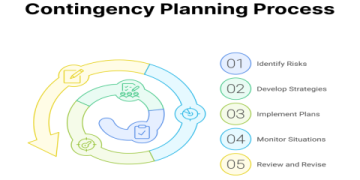

Talking about theory is one thing. Taking action is another. Follow this five-step plan to start building a more resilient operation today.

STEP 1: MAP AND ASSESS YOUR END-TO-END NETWORK. You cannot protect what you cannot see. Document every tier of your supply chain, not just your direct (Tier 1) suppliers. Identify Tier 2 and Tier 3 suppliers for critical components. Assess each node for single points of failure, geographic concentration, and financial health.

STEP 2: DIVERSIFY YOUR SUPPLIER AND LOGISTICS BASE. Over-reliance on a single region, port, or supplier is a top vulnerability. Actively seek and qualify alternative suppliers in different geographic locations. Explore nearshoring or friendshoring opportunities. Similarly, build relationships with multiple logistics carriers to avoid being locked into one option.

STEP 3: INVEST IN SUPPLY CHAIN VISIBILITY TECHNOLOGY. Modern retail supply chain risk management is data-driven. Implement tools that provide real-time tracking of shipments, inventory levels across channels, and supplier performance. Technologies like AI can analyze this data to predict potential delays or demand spikes before they become crises.

STEP 4: DEVELOP AND REGULARLY TEST CONTINGENCY PLANS. A plan on paper is useless if it has not been tested. For your highest-priority risks, create detailed playbooks. What do we do if our main port shuts down? If a key supplier has a fire? Conduct tabletop exercises with your team and key partners at least annually to ensure everyone knows their role.

STEP 5: FOSTER A CULTURE OF COLLABORATION AND AGILITY. Break down internal silos between procurement, logistics, sales, and finance. Share information and goals. Empower teams to make quick decisions in a crisis. According to my experience consulting for mid-sized retailers, the companies that recover fastest from disruptions are those where teams communicate openly and are empowered to act without waiting for layers of approval.

## Common Pitfalls and What to Avoid

WARNING: DO NOT MAKE THESE CRITICAL MISTAKES

A major mistake is treating supply chain resilience as a one-time project. It is a continuous process that requires ongoing investment and executive attention. Another common error is focusing solely on cost. Choosing the cheapest supplier or carrier often means accepting higher, hidden levels of retail supply chain risk. Finally, do not neglect cybersecurity. Your supply chain is only as strong as the digital systems that manage it. A breach at a small software vendor can compromise your entire network.

## Your Retail Supply Chain Resilience Checklist

Use this practical checklist to audit your current posture and guide your next steps. A simple yes or no evaluation can reveal glaring gaps.

IDENTIFY AND DOCUMENT all Tier 1, 2, and 3 suppliers for your top 20% of products by revenue.

ESTABLISH clear, quantified metrics for supplier performance beyond just cost.

IMPLEMENT a supply chain visibility platform with real-time tracking capabilities.

MAINTAIN strategic safety stock for critical, long-lead-time items.

DEVELOP and DOCUMENT contingency plans for at least three high-impact disruption scenarios.

DESIGNATE a cross-functional crisis response team with clear leadership.

CONDUCT a supply chain cybersecurity assessment annually.

NEGOTiate contracts with key partners that include resilience and data-sharing clauses.

DIVERSIFY logistics routes and have backup carriers identified.

REVIEW and UPDATE all risk assessments and plans at least every six months.

Building a resilient retail operation is a journey. By systematically understanding the categories of retail supply chain risk, shifting from a reactive to a proactive stance, and following the structured action plan above, you can transform your supply chain from a point of vulnerability into a source of durable competitive advantage. Start today.