# The Ultimate Guide to Outsourcing in Supply Chain: Strategies, Risks, and a 7-Step Implementation Plan

Outsourcing in supply chain management is no longer just a cost-cutting tactic. It has evolved into a sophisticated strategic lever for building resilience, accessing specialized expertise, and driving innovation. For modern businesses, understanding how to effectively leverage third-party partnerships is not optional; it is essential for competitive survival. This comprehensive guide dives deep into the why, what, and how of supply chain outsourcing, providing you with the insights and actionable steps needed to make informed decisions.

At its core, supply chain outsourcing involves delegating specific logistics, manufacturing, or service functions to external specialists. This move allows companies to focus on their core competencies—like product development, marketing, and customer relationships—while experts handle the complexities of warehousing, transportation, or procurement. The global logistics market, a key component of this ecosystem, was valued at over USD 10 trillion in 2023 and continues to grow, underscoring the scale of this practice (来源: Statista).

However, the journey is fraught with both immense opportunity and significant risk. A poorly managed outsourcing partnership can lead to quality issues, loss of control, and severe reputational damage. This guide will equip you with the knowledge to navigate this landscape successfully.

## Understanding the Core Models of Supply Chain Outsourcing

Not all outsourcing is created equal. The model you choose depends entirely on your strategic goals, operational complexity, and risk appetite. Broadly, we can categorize the approach into three primary models.

The first is logistics outsourcing. This is the most common entry point. Companies partner with third-party logistics providers, known as 3PLs, to manage transportation, warehousing, and order fulfillment. For many, this is the first step in externalizing non-core activities.

The second model is manufacturing outsourcing. Here, the entire production process is handed over to a contract manufacturer. This is prevalent in industries like electronics, apparel, and pharmaceuticals, where capital investment in factories is prohibitive.

The third is specialized service outsourcing. This includes outsourcing specific functions like procurement, inventory management, demand planning, or even IT support for supply chain software. It allows access to niche skills without long-term hiring commitments.

## The Compelling Benefits: Why Companies Choose to Outsource

The drivers for adopting an outsourced supply chain model are powerful and multifaceted. The most cited advantage is cost reduction. By outsourcing, companies convert fixed costs (like warehouse leases and salaried truck drivers) into variable costs. They also benefit from the provider’s economies of scale and negotiated carrier rates.

Access to expertise and technology is another major benefit. Top-tier logistics partners invest heavily in warehouse management systems, transportation management systems, and real-time tracking technologies. Gaining access to this tech stack without the capital outlay and implementation headache is a huge advantage.

Furthermore, outsourcing enhances scalability and flexibility. During peak seasons like holidays, a 3PL can quickly ramp up warehouse space and labor. Conversely, during a downturn, you can scale down without the pain of layoffs or idle capacity. This agility is crucial in today’s volatile market.

Finally, it allows a sharp focus on core business functions. By offloading complex logistics operations, your internal team can dedicate more time to innovation, customer service, and strategic growth initiatives.

## The Inherent Risks and How to Mitigate Them

While the benefits are clear, a naive approach to outsourcing can backfire. Recognizing these pitfalls is the first step toward avoiding them.

Loss of direct control is a primary concern. When a critical process is in someone else’s hands, you rely on their performance. Any failure on their part—a shipping delay, a picking error—directly impacts your customer.

Quality consistency can suffer if not meticulously managed. A manufacturer or packer that does not share your quality standards can damage your brand reputation. Intellectual property risk is especially pertinent in manufacturing outsourcing, where product designs and proprietary processes are shared.

There is also the risk of hidden costs. The initial quoted price may not include fees for special handling, returns processing, or peak-season surcharges, leading to cost creep.

COMMON MISCONCEPTION: A common and dangerous misconception is that outsourcing eliminates management responsibility. In reality, it shifts your role from operator to manager of a partnership. Your oversight, performance monitoring, and relationship management become more critical, not less.

## Critical Evaluation: In-House vs. Outsourced Logistics

To make a data-driven decision, a clear comparison is vital. The following table outlines the key trade-offs between managing logistics internally versus partnering with a 3PL.

| Factor | In-House Logistics | Outsourced Logistics (3PL) |

|---|---|---|

| Capital Investment | HIGH: Requires investment in warehouses, fleet, technology. | LOW: Provider owns assets; you pay for services. |

| Operational Control | COMPLETE: Direct oversight of all processes and staff. | SHARED: Dependent on contract and SLA management. |

| Expertise & Technology | INTERNAL: Must build and maintain expertise and systems. | ACCESS: Leverage provider’s specialized skills and tech. |

| Scalability | INFLEXIBLE: Scaling up/down is slow and costly. | HIGHLY FLEXIBLE: Can adjust capacity based on demand. |

| Cost Structure | Mostly FIXED: Salaries, leases, depreciation. | Mostly VARIABLE: Pay-per-use or transactional fees. |

| Risk Profile | You bear all operational and asset risks. | Risk is shared; provider manages day-to-day operational risk. |

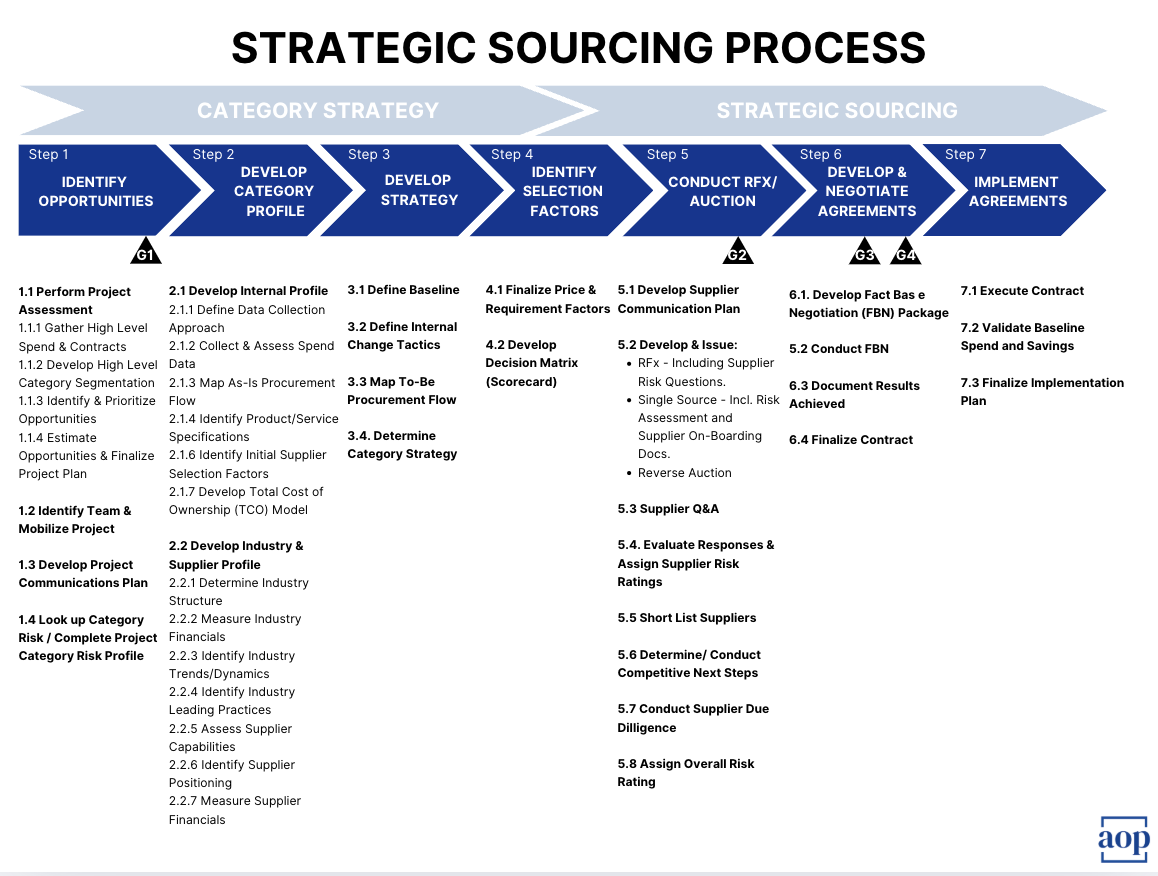

## Your 7-Step Roadmap for Successful Implementation

A successful outsourcing transition does not happen by accident. It requires a disciplined, phased approach. Follow this seven-step plan to build a strong foundation.

STEP 1: Conduct an Internal Strategic Assessment.

Identify exactly which functions are candidates for outsourcing. Ask: Is this a core competency? Are we struggling with cost or performance? Is internal expertise lacking? Be brutally honest.

STEP 2: Define Clear Objectives and KPIs.

What does success look like? Is it a 15% cost reduction, 99.5% order accuracy, or next-day delivery capability? Establish Specific, Measurable, Achievable, Relevant, and Time-bound goals.

STEP 3: Develop a Detailed Request for Proposal.

Your RFP is your blueprint. It should detail your current volumes, future growth projections, required services, technology integration needs, and the KPIs from Step 2. This ensures all bidders are evaluated on the same criteria.

STEP 4: Rigorously Vet and Select Partners.

Go beyond price. Conduct site visits, check financial stability, interview their operational teams, and speak to current clients. Look for a cultural fit and a partner who acts as an extension of your business.

STEP 5: Negotiate a Comprehensive Contract and SLA.

The Service Level Agreement is your governance bible. It must define every KPI, reporting frequency, issue escalation path, penalty for non-performance, and review mechanism. Leave no room for ambiguity.

STEP 6: Plan and Execute a Phased Transition.

Do not flip the switch overnight. Start with a pilot project or a single region. Run parallel operations for a period. This allows you to iron out kinks in processes and technology integration before full-scale launch.

STEP 7: Manage the Relationship Proactively.

After go-live, assign a dedicated relationship manager. Hold regular business review meetings to discuss performance, challenges, and improvement opportunities. View this as a strategic partnership, not a vendor transaction.

In my experience consulting with mid-sized manufacturers, the most successful outsourcing engagements are those where the client invests heavily in Steps 1 and 5. A vague internal scope leads to a mismatched partner, and a weak SLA leads to endless disputes. The companies that nail these two steps build partnerships that last for decades.

## The Future of Supply Chain Outsourcing

The landscape is continuously evolving. The rise of Fourth-Party Logistics providers, who manage multiple 3PLs to orchestrate an entire supply chain, offers even higher-level strategic oversight. Furthermore, the integration of advanced technologies like artificial intelligence for predictive analytics and blockchain for enhanced transparency is becoming a key differentiator. Providers offering these capabilities will lead the next wave of supply chain outsourcing innovation.

Interestingly, the post-pandemic world has added a new dimension: resilience. Companies now seek partners with diversified networks and real-time risk mitigation capabilities, not just the lowest cost. This shift from pure cost focus to value and resilience focus is reshaping selection criteria.

IMPLEMENTATION CHECKLIST

– Completed internal process audit and identified non-core functions.

– Defined specific, measurable goals for cost, service, and scalability.

– Created a detailed RFP document with technical and operational requirements.

– Shortlisted partners based on capability, culture, and financial health, not just price.

– Negotiated a contract with a robust SLA covering all critical KPIs and remedies.

– Developed a phased transition plan with clear milestones and rollback options.

– Assigned an internal relationship manager and scheduled quarterly strategic reviews.

– Established integrated systems for data visibility and performance reporting.

– Planned for continuous improvement and regular contract re-evaluation.

By following the principles and steps outlined in this guide, you can transform outsourcing in your supply chain from a tactical cost-saver into a powerful strategic asset. The goal is to build an agile, expert-driven, and resilient ecosystem that allows your business to thrive in an unpredictable world. Start your assessment today, and take the first step toward a more focused and competitive future.