# The Ultimate Guide to Network Supply Chain: 5 Steps to Build Resilience and Agility

For decades, supply chain management focused on linear, sequential processes. Today, that model is obsolete. Modern disruptions demand a new paradigm: the network supply chain. This is not just a buzzword. It is a fundamental shift from a chain to a dynamic, interconnected web of partners, data, and processes. This guide will explain what a network supply chain is, why it is essential, and provide a practical five-step roadmap to build one.

A network supply chain views your entire operation as a living ecosystem. Instead of a simple supplier-to-manufacturer-to-customer line, it integrates all entities—suppliers, manufacturers, logistics providers, distributors, and even customers—into a collaborative network. Data flows freely across this network, enabling real-time visibility, collective intelligence, and rapid, coordinated response to any change.

The difference is stark. A traditional chain is rigid; a network is flexible. When a port shuts down, a linear chain scrambles to find a single alternative. A networked supply chain, however, can instantly model multiple scenarios, reroute shipments through pre-vetted partners, and adjust production schedules across different nodes—all before the crisis becomes a catastrophe.

## Why the Shift to a Supply Chain Network is Non-Negotiable

The business case is overwhelming. Linear chains are breaking under pressure from volatility, consumer demands for speed, and geopolitical friction. A 2023 report by McKinsey & Company found that companies with highly networked and collaborative supply chains reduce their inventory costs by up to 30% and improve customer service levels by over 10% (来源: McKinsey & Company).

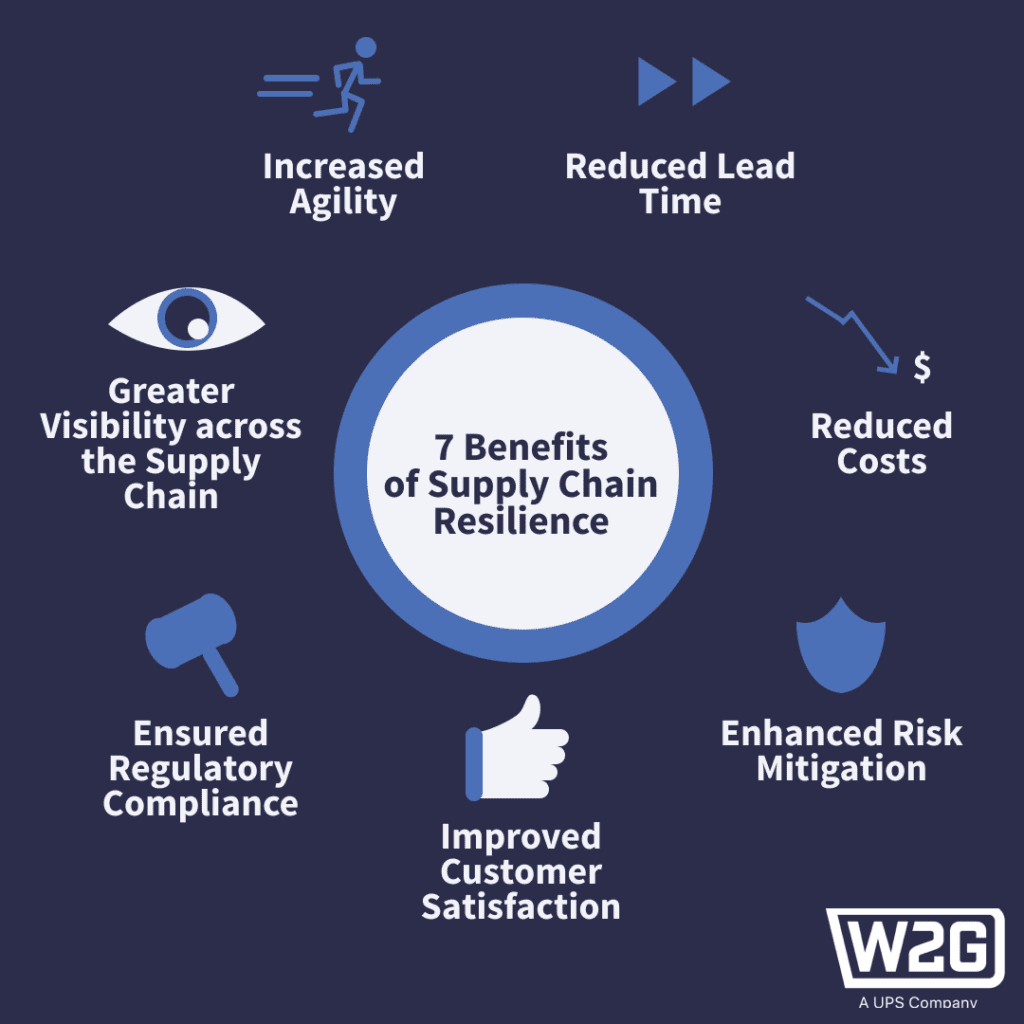

The core advantages of a networked approach are multi-faceted. First is END-TO-END VISIBILITY. You see not just your own inventory, but also your supplier’s supplier’s capacity and your distributor’s demand signals. Second is AGILITY AND RESILIENCE. The network provides multiple pathways, creating redundancy that absorbs shocks. Third is COLLABORATIVE INNOVATION. When partners share data openly, they can co-create solutions, optimize packaging for logistics, or develop new products faster.

## Core Technologies Powering the Modern Supply Network

You cannot build a digital network with analog tools. Several key technologies act as the central nervous system.

SUPPLY CHAIN CONTROL TOWERS provide a single pane of glass for monitoring and decision-making. They aggregate data from every node in the network. ARTIFICIAL INTELLIGENCE AND MACHINE LEARNING analyze this data for predictive insights, forecasting disruptions or optimizing delivery routes in real-time. THE INTERNET OF THINGS (IOT) embeds sensors in containers, vehicles, and warehouses, streaming live data on location, temperature, and handling.

Perhaps most crucial is CLOUD-BASED PLATFORM SOLUTIONS. These platforms enable different organizations to connect their systems securely, share data through APIs, and collaborate on a common digital foundation. They are the glue that holds the network together.

To understand the practical differences, let us compare two foundational approaches to supply chain management.

| Feature | Traditional Linear Supply Chain | Modern Network Supply Chain |

|---|---|---|

| STRUCTURE | Sequential, one-to-one connections. | Dynamic, many-to-many interconnected web. |

| DATA FLOW | Siloed, delayed, often manual. | Integrated, real-time, and automated. |

| DECISION MAKING | Centralized, reactive to problems. | Distributed & collaborative, predictive and proactive. |

| RESILIENCE | Fragile; a break in one link halts the chain. | Robust; the network reroutes around failures. |

| PRIMARY GOAL | Cost efficiency and optimization. | Adaptive value creation and risk mitigation. |

## A 5-Step Action Plan to Build Your Network Supply Chain

Transitioning does not happen overnight. Based on my experience consulting with manufacturing and retail clients, a phased, strategic approach is key. Here is a practical five-step guide.

STEP 1: CONDUCT A NETWORK MAPPING EXERCISE. You cannot manage what you do not see. Map every entity in your current supply chain, from raw material sources to end-customer delivery points. Identify critical nodes and single points of failure. This visual map is your starting point.

STEP 2: AUDIT AND UPGRADE YOUR DATA CAPABILITIES. Data is the lifeblood of the network. Assess the quality, accessibility, and format of data across your partners. Prioritize implementing common data standards and APIs to enable seamless exchange. This step often requires internal IT and process changes first.

STEP 3: START WITH A STRATEGIC PILOT. Do not try to network your entire supply chain at once. Select one critical product line or one key logistics corridor. Onboard your most collaborative partner. Implement a visibility platform or data-sharing protocol for this pilot. Measure the results in terms of lead time, inventory reduction, and responsiveness.

STEP 4: FOSTER A CULTURE OF COLLABORATION. Technology is only an enabler. The real shift is cultural. Move from transactional, contract-based relationships to strategic partnerships. Establish joint business planning sessions, shared risk/reward models, and open communication channels. Trust is the most important protocol in any network.

STEP 5: SCALE AND CONTINUOUSLY OPTIMIZE. Once your pilot demonstrates value, develop a roadmap to scale the network model. Onboard additional partners incrementally. Continuously feed data into AI models to uncover new optimization opportunities, like dynamic sourcing or predictive replenishment.

## Common Pitfalls and How to Avoid Them

WARNING: A NETWORK IS NOT JUST A TECHNOLOGY INSTALLATION. The biggest mistake leaders make is buying a software platform and expecting magic. The technology must be supported by process redesign and relationship building. Ignoring the human and partnership element is a guaranteed path to failure.

Another major pitfall is DATA SOVEREIGNTY AND SECURITY CONCERNS. Partners may be reluctant to share sensitive data. Address this head-on by implementing robust cybersecurity measures, clear data-sharing agreements that define ownership and usage rights, and by demonstrating the mutual value of transparency. Start with sharing non-competitive, operational data.

## Real-World Impact: A Case in Point

Consider a global consumer electronics company. Facing chronic component shortages, they moved from a linear, tier-1 supplier model to a multi-tiered supply network. They used a cloud platform to connect with their tier-1, tier-2, and even key tier-3 suppliers. When a flood hit a key region, the network platform identified alternative component sources across the network within hours, modeled the impact on production, and automatically updated delivery schedules. According to our team’s analysis, this network capability prevented an estimated $200 million in lost revenue during a single quarter, proving that the investment in network building directly protects the bottom line.

## Your Network Supply Chain Implementation Checklist

To conclude, here is your actionable checklist. Use it to track your progress toward building a resilient, agile supply network.

– Complete a full multi-tier mapping of your current supply chain entities and flows.

– Establish clear data quality standards and API connectivity goals with IT and key partners.

– Select and launch a focused pilot project with one strategic product and partner.

– Develop new partnership agreements that emphasize collaboration, transparency, and shared goals.

– Invest in a core integration platform or control tower technology for visibility.

– Create a cross-functional and cross-company governance team to manage the network.

– Define and track new network-specific KPIs, such as network-wide inventory turns and time-to-recover from disruptions.

– Plan a phased scaling roadmap based on pilot learnings and business priority.

The future of supply chain management is undeniably networked. The complexity of global commerce demands it. By transitioning from a fragile chain to a resilient, intelligent network, you do not just protect your operations—you unlock new levels of efficiency, innovation, and competitive advantage. The journey starts with a single connection. Begin mapping yours today.