# The Ultimate Guide to Iron and Chains: From History to Modern Applications

Iron and chains are fundamental to our world. They represent both raw strength and intricate connection. This guide explores everything about iron and chains, from their ancient origins to their critical modern uses. We will look at types, manufacturing, and key selection criteria.

Many people see chains as simple tools. However, the reality is far more complex. Choosing the wrong chain for a job can lead to failure, damage, or serious injury. This article provides the expert knowledge you need to make informed decisions.

We will answer common questions. What are the different grades of chain? How is a chain’s working load limit determined? What are the hidden risks in chain maintenance? By the end, you will have a clear, actionable understanding.

## The Historical Link: How Iron and Chains Shaped Civilization

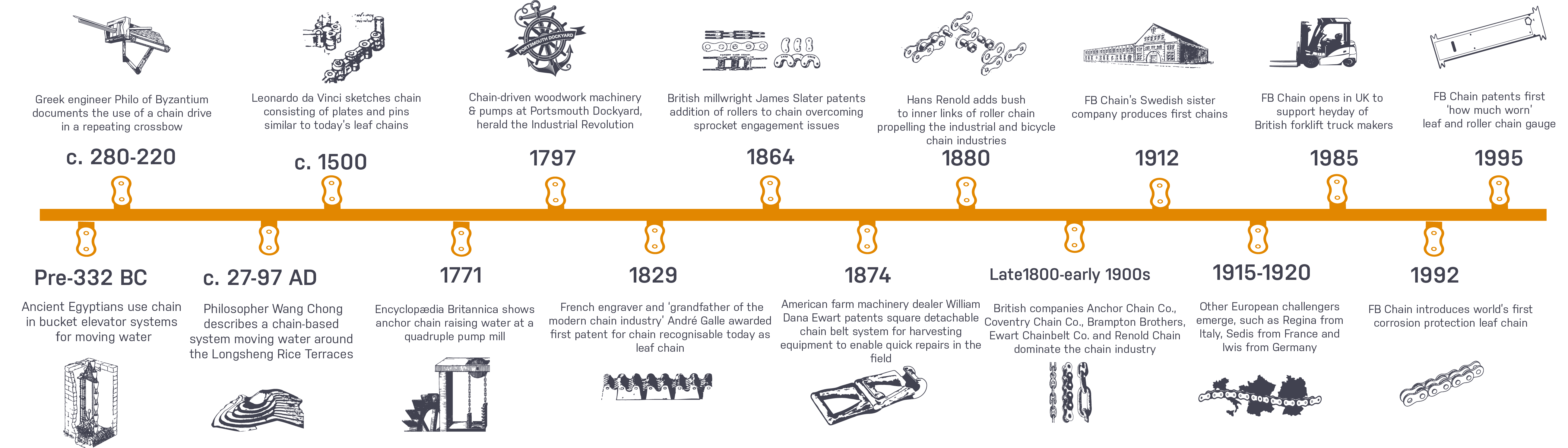

The story of iron and chains is the story of human progress. The Iron Age, beginning around 1200 BCE, was a revolutionary period. Iron, stronger and more abundant than bronze, changed warfare, agriculture, and construction.

Early chains were likely used for restraint and for simple lifting devices. The technology evolved with blacksmithing. For centuries, chains were hand-forged, link by link. The Industrial Revolution mechanized this process. The invention of the Bessemer process in the 1850s made mass production of steel—an iron alloy—possible. This directly led to the standardized, high-strength chains we use today.

Chains enabled maritime exploration by securing anchors. They drove industrial machinery via drive chains. They built suspension bridges. This historical context is crucial. It shows that the development of iron and chains is a key indicator of technological advancement.

## Understanding Modern Chain Types and Their Specifications

Not all chains are created equal. The material and construction define its purpose. The term “iron chain” is often used colloquially, but most modern chains are made from steel, which is iron combined with carbon and other elements for strength.

Here are the primary types you will encounter:

TRANSMISSION CHAINS: These are designed to transfer mechanical power from one gear to another. Think of a bicycle chain. They are precision-engineered for smooth, efficient movement with minimal stretch.

LIFTING AND RIGGING CHAINS: These are workhorses for industry. Made from alloy steel, they are built for strength and safety. They come in grades, like Grade 80 or Grade 100, which indicate their minimum breaking force.

DECORATIVE CHAINS: Used in architecture, fencing, and jewelry. They prioritize aesthetics but still require proper material selection for environmental durability.

MARINE CHAINS: Specifically designed to resist corrosion in saltwater. They are often galvanized or made from stainless steel.

SECURITY CHAINS: Built to resist cutting and sawing. They often have hardened steel links and complex weaves to deter theft.

Selecting the correct type is the first and most critical step. Using a decorative chain for lifting or a transmission chain for security would be a dangerous mistake.

## Critical Factors: Breaking Strength, Working Load Limit, and Safety

This is the most important section for anyone using chains for load-bearing applications. Understanding these terms is non-negotiable for safety.

BREAKING STRENGTH: This is the absolute maximum force a chain can withstand in a single pull before it fractures. It is a theoretical limit tested in controlled conditions.

WORKING LOAD LIMIT (WLL): This is the maximum force that should ever be applied to a chain during normal use. It is calculated by dividing the Minimum Breaking Strength by a safety factor (often 4:1 for lifting chains). For example, a chain with a 10,000-pound breaking strength has a 2,500-pound WLL with a 4:1 safety factor. YOU MUST NEVER EXCEED THE WLL.

SAFETY FACTOR: This accounts for variables like dynamic shock loads, wear, material flaws, and attachment point weaknesses. It is your buffer against catastrophe.

According to the Occupational Safety and Health Administration (OSHA), failures in lifting equipment, including chains, are a leading cause of serious incidents in industrial settings (来源: OSHA.gov). Always inspect a chain before use. Look for stretched links, cracks, wear, and corrosion. If in doubt, take it out of service.

## Side-by-Side Comparison: Alloy vs. Stainless Steel Chains

Choosing between alloy steel and stainless steel chains depends on your primary need: supreme strength or corrosion resistance. The following table breaks down the key differences.

| Feature | Alloy Steel Chain (e.g., Grade 80) | Stainless Steel Chain (e.g., 316 Grade) |

|---|---|---|

| PRIMARY USE | Lifting, rigging, towing, logging | Marine, food processing, chemical, decorative |

| MAXIMUM STRENGTH | Very High. Designed for heavy load-bearing. | Moderate to High. Strong but not typically at alloy levels. |

| CORROSION RESISTANCE | Low. Requires regular coating or galvanization. | Exceptionally High. Resists rust and chemical attack. |

| COST | Moderate. Cost-effective for high-strength needs. | High. Premium material commands a higher price. |

| MAINTENANCE | Higher. Needs inspection for rust and wear. | Lower. Primarily needs cleaning, not rust prevention. |

## A Step-by-Step Guide to Proper Chain Inspection

Regular inspection is not a suggestion; it is a requirement for safety. Follow this five-step guide before every use.

STEP 1: CLEAN THE CHAIN. Wipe off dirt and grease to get a clear view of the metal surface.

STEP 2: CHECK FOR WEAR. Measure several links. Compare their inside length to a new link’s length. If any link is stretched beyond the manufacturer’s tolerance (often 3-5%), the chain is unsafe.

STEP 3: LOOK FOR DAMAGE. Visually inspect each link for cracks, nicks, gouges, or corrosion pitting. Pay special attention to the weld points and contact areas.

STEP 4: EXAMINE THE ATTACHMENTS. Inspect hooks, shackles, or connectors for distortion, cracks, or wear. The chain is only as strong as its weakest link, literally.

STEP 5: REVIEW DOCUMENTATION. For certified lifting chains, ensure the identification tag is legible and the chain hasn’t exceeded its inspection interval.

Based on my experience, most chain failures in industrial settings can be traced back to a missed inspection step or the use of a chain that was visibly compromised. The human eye is a powerful tool if used systematically.

## Common Mistakes and Misconceptions About Chain Use

A WARNING ON CRITICAL ERRORS

Many accidents happen due to widespread misconceptions. Let us clarify them now.

MISTAKE 1: USING GRADE 30 TRANSPORT CHAIN FOR LIFTING. This is extremely dangerous. Grade 30 (“proof coil”) chain is for tying down loads, not overhead lifting. It has a much lower safety factor.

MISTAKE 2: REPAIRING A CHAIN BY WELDING A BROKEN LINK. Never do this. The heat from welding alters the metallurgy of the steel, creating a brittle zone that will fail under load. A repaired chain has no reliable working load limit.

MISTAKE 3: ASSUMING SIZE EQUALS STRENGTH. A thick, low-grade chain can be weaker than a thinner, high-grade alloy chain. Always go by the grade and WLL stamp, not by visual thickness alone.

MISTAKE 4: IGNORING ANGLE LOADS. When a chain is used in a choke or basket hitch, the tension on the legs increases dramatically as the angle widens. A 2015 study by the Lifting Equipment Engineers Association noted that a 120-degree angle can double the load on each leg (来源: LEEA). Always use angle calculation charts.

## The Future of Iron and Chains: Innovation and Smart Technology

The evolution continues. Today, researchers are developing chains with embedded fiber optics to monitor stress and strain in real-time. High-performance polymer coatings are increasing service life in abrasive environments.

In robotics and automation, precision roller chains are becoming quieter and more efficient. There is even work on “smart security chains” integrated with GPS and tamper alarms. The core material may still be iron-based, but its capabilities are expanding into the digital age.

The fundamental principles of strength, safety, and proper application will never change. However, the tools to ensure those principles are becoming more sophisticated.

## Your Iron and Chains Application Checklist

Use this final checklist to ensure safety and correctness in your next project. Do not proceed unless you can answer YES to every point.

IDENTIFY THE PRIMARY PURPOSE: Lifting, securing, transmitting power, or decoration.

SELECT THE CORRECT CHAIN TYPE AND MATERIAL: Alloy for lifting, stainless for corrosion, etc.

CONFIRM THE WORKING LOAD LIMIT (WLL): Ensure it exceeds your maximum planned load with a safety margin.

CHECK FOR COMPATIBLE ATTACHMENTS: Hooks, shackles, and connectors must be of matching or higher grade.

CONDUCT A PRE-USE VISUAL INSPECTION: Follow the five-step guide outlined above.

CONSIDER ENVIRONMENTAL FACTORS: Corrosion, temperature, and abrasion can degrade performance.

PLAN FOR PROPER STORAGE: Keep chains clean, dry, and coiled to prevent kinking and damage.

Iron and chains are more than simple tools. They are engineered components with a rich history and a critical role in modern industry. By respecting their specifications and limitations, you harness their strength safely and effectively.