# The Ultimate Guide to GEP Supply Chain: 5 Steps to Transform Your Procurement and Operations

In today’s volatile global market, managing a supply chain feels less like a logistical operation and more like navigating a storm. Disruptions, cost pressures, and sustainability demands are constant challenges. This is where a dedicated GEP supply chain platform becomes not just a tool, but a strategic lifeline. But what exactly is GEP, and how can its solutions propel your business forward? This comprehensive guide dives deep into the world of GEP SMART and GEP NEXXE, providing you with the insights, strategies, and a clear action plan to evaluate and implement this powerful technology.

GEP stands as a leading provider of procurement and supply chain software and consulting services. Their flagship platforms, GEP SMART for procurement and GEP NEXXE for supply chain management, are designed to unify and optimize the entire source-to-pay and plan-to-deliver cycles. The core promise is to deliver tangible value through increased efficiency, significant cost savings, enhanced visibility, and mitigated risk. For any executive or manager wrestling with fragmented systems and data silos, understanding the GEP supply chain ecosystem is a critical step toward resilience.

## Understanding the GEP Supply Chain Ecosystem

At its heart, the GEP approach is about unification. Traditional enterprises often suffer from a patchwork of legacy systems for procurement, logistics, inventory, and contracts. This fragmentation creates blind spots. GEP platforms aim to be a single, cloud-native source of truth. GEP SMART focuses on the upstream: sourcing, contracting, supplier management, and procurement. GEP NEXXE handles the downstream: supply chain planning, logistics, warehousing, and transportation.

Interestingly, their power is amplified when used together, creating a seamless flow from identifying a need to delivering the final product. This integrated view is what sets a modern GEP supply chain strategy apart from using point solutions. It allows for predictive insights, like understanding how a sourcing decision in Shanghai impacts warehouse capacity in Chicago next quarter.

## Key Capabilities and Benefits of Implementing GEP Solutions

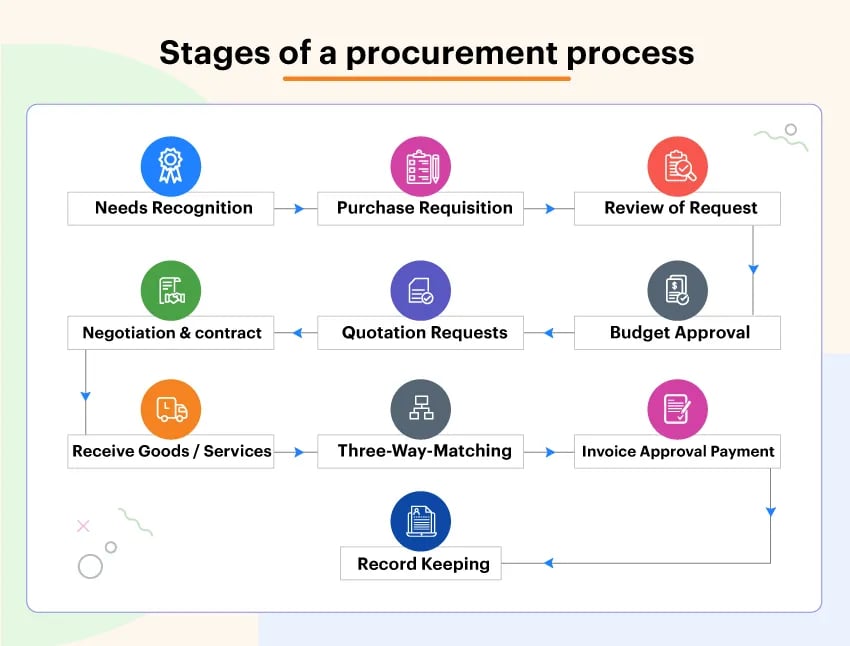

Deploying a GEP supply chain platform unlocks a suite of capabilities that translate directly into business benefits. First is spend analysis and visibility. Companies gain a crystal-clear view of where every dollar goes, identifying savings opportunities that were previously hidden. Second is automated procurement workflows, which reduce manual processing, errors, and cycle times. A study by Ardent Partners found that best-in-class procurement teams have 80% of their invoices processed electronically, a feat enabled by platforms like GEP (source: Ardent Partners State of Procurement Report).

Third is advanced supplier management, fostering collaboration and performance tracking. Fourth, and crucially for supply chain, is integrated planning. GEP NEXXE offers demand planning, inventory optimization, and logistics coordination on a single platform. This leads to reduced stockouts, lower carrying costs, and improved service levels. According to GEPs own client data, businesses often achieve a 10-15% reduction in supply chain costs post-implementation (source: GEP Client Performance Benchmarks). The overarching benefit is risk resilience; with full visibility and AI-driven analytics, companies can simulate disruptions and pivot strategies proactively.

## GEP SMART vs. GEP NEXXE: A Detailed Feature Comparison

While complementary, GEP SMART and GEP NEXXE serve distinct primary functions. The table below breaks down their core focuses to help you understand which platform, or combination, is right for your needs.

| Feature Area | GEP SMART (Procurement Focus) | GEP NEXXE (Supply Chain Focus) |

|---|---|---|

| PRIMARY FUNCTION | Source-to-Pay (S2P) Optimization | Plan-to-Deliver (P2D) Optimization |

| CORE MODULES | Spend Analysis, Sourcing, Contracts, Supplier Management, Procure-to-Pay | Demand Planning, Inventory Management, Logistics & Transportation, Warehouse Management |

| KEY METRIC IMPACT | Cost Savings, Supplier Performance, Maverick Spend Reduction, Process Efficiency | Perfect Order Rate, Inventory Turnover, Transportation Cost, On-Time In-Full (OTIF) Delivery |

| TYPICAL USERS | Chief Procurement Officer, Category Managers, Sourcing Specialists | Supply Chain Director, Logistics Managers, Demand Planners, Warehouse Supervisors |

| TECHNOLOGY HIGHLIGHT | AI for spend classification and contract analytics | AI for demand forecasting and network optimization |

## The 5-Step Implementation Roadmap for GEP Supply Chain Success

A successful GEP supply chain transformation is not just about installing software. It is a strategic journey. Based on my experience consulting with mid-sized manufacturers, skipping the groundwork is the most common reason for subpar results. Follow this actionable roadmap.

STEP 1: INTERNAL DIAGNOSIS AND GOAL SETTING.

Begin by conducting a thorough audit of your current procurement and supply chain processes. Map out pain points, data sources, and key stakeholders. Define clear, measurable objectives. Are you targeting a 15% reduction in logistics costs? A 20% improvement in supplier on-time delivery? Quantify your goals.

STEP 2: DATA CLEANSING AND PREPARATION.

This is the unglamorous but critical phase. Garbage in, garbage out. Cleanse your supplier, item, and spend data. Standardize classifications and units of measure. Our team has seen projects where 70% of the initial effort was dedicated to data hygiene, but it laid the foundation for flawless automation later.

STEP 3: PHASED PILOT DEPLOYMENT.

Do not attempt a big-bang rollout. Select a specific category (like IT procurement for GEP SMART) or a single product line (for GEP NEXXE) to pilot. This limits risk, allows for learning, and helps build a case study to champion wider adoption.

STEP 4: CONFIGURATION, INTEGRATION, AND TRAINING.

Work with GEP consultants to configure the platform to your specific workflows. Ensure robust integration with your ERP (like SAP or Oracle) and other critical systems. Simultaneously, invest heavily in change management and user training. Adoption is the true driver of ROI.

STEP 5: GO-LIVE, MONITORING, AND CONTINUOUS OPTIMIZATION.

Launch the pilot, monitor KPIs closely against your baseline, and gather user feedback. Use the platforms analytics to identify new improvement opportunities. Then, methodically expand the rollout to other categories or regions.

## Common Pitfalls to Avoid During Your GEP Journey

WARNING: UNDERESTIMATING THE HUMAN ELEMENT.

The most advanced GEP supply chain platform will fail if people do not use it. A common pitfall is treating the implementation as a pure IT project. It is a business transformation project. Secure executive sponsorship from the start, involve end-users in design sessions, and communicate the WIIFM (Whats In It For Me) clearly. Resistance to change is the single biggest barrier.

Another major mistake is neglecting ongoing support and optimization. The go-live is not the finish line. The market changes, your business evolves, and new platform features are released. Plan for a dedicated internal administrator and a continuous improvement mindset to extract long-term value.

## Your GEP Supply Chain Evaluation Checklist

Before you engage with any vendor, use this practical checklist to assess your organizations readiness and define your requirements. This will ensure productive conversations and a solution tailored to your needs.

BUSINESS CASE CLARITY: We have documented our top 3-5 pain points and defined specific, quantitative goals for improvement.

STAKEHOLDER ALIGNMENT: We have identified an executive sponsor and key users from both procurement and supply chain operations.

DATA READINESS ASSESSMENT: We have audited our master data quality for suppliers, materials, and spend categories.

INTEGRATION SCOPE: We have mapped the key systems (ERP, CRM, etc.) that must connect with the new platform.

CHANGE MANAGEMENT PLAN: We have a draft plan for communication, training, and measuring user adoption.

BUDGET AND TIMELINE: We have preliminary approval for the investment and a realistic timeline for a phased approach.

VENDOR EVALUATION CRITERIA: We have a scorecard to evaluate GEP and other potential vendors on functionality, support, and total cost of ownership.

The journey to a smarter, more resilient supply chain starts with a single step: education and assessment. By understanding the depth of GEP supply chain solutions and following a disciplined approach, you can transform a cost center into a powerful engine for competitive advantage and growth. The question is no longer if you should modernize, but how quickly you can begin.