A robust animal health supply chain is the unseen backbone of modern agriculture, veterinary medicine, and global food security. It is a complex network that moves everything from essential vaccines and antibiotics to specialized feed additives and diagnostic equipment. When this chain functions smoothly, it ensures the well-being of billions of farm animals, pets, and wildlife. However, when it breaks down, the consequences can be severe, leading to animal suffering, economic losses for farmers, and public health risks. This guide delves deep into the critical components, common vulnerabilities, and expert strategies for fortifying the animal health supply chain against disruption.

# Understanding the Animal Health Supply Chain Ecosystem

The animal health supply chain is not a single pipeline but a multifaceted ecosystem. It begins with the research and development of products by pharmaceutical and biotech companies. Following regulatory approval, these products move through primary manufacturers, secondary packagers, and then into the distribution network. This network includes wholesalers, distributors, and direct sales channels that finally deliver the products to the end-points of care: veterinary clinics, farms, feed mills, and animal hospitals. Each node in this chain is interdependent, and a delay or failure at any point can ripple through the entire system.

KEY COMPONENTS INCLUDE:

– Pharmaceuticals: Vaccines, parasiticides, antibiotics, and therapeutics.

– Biologicals: Serums, antibodies, and other products derived from living organisms.

– Feed Additives: Nutritional supplements, medications, and probiotics mixed into animal feed.

– Diagnostics: Test kits, lab equipment, and monitoring devices.

– Medical Equipment: Surgical tools, imaging machines, and wearable health monitors.

# Major Challenges and Vulnerabilities in the Supply Chain

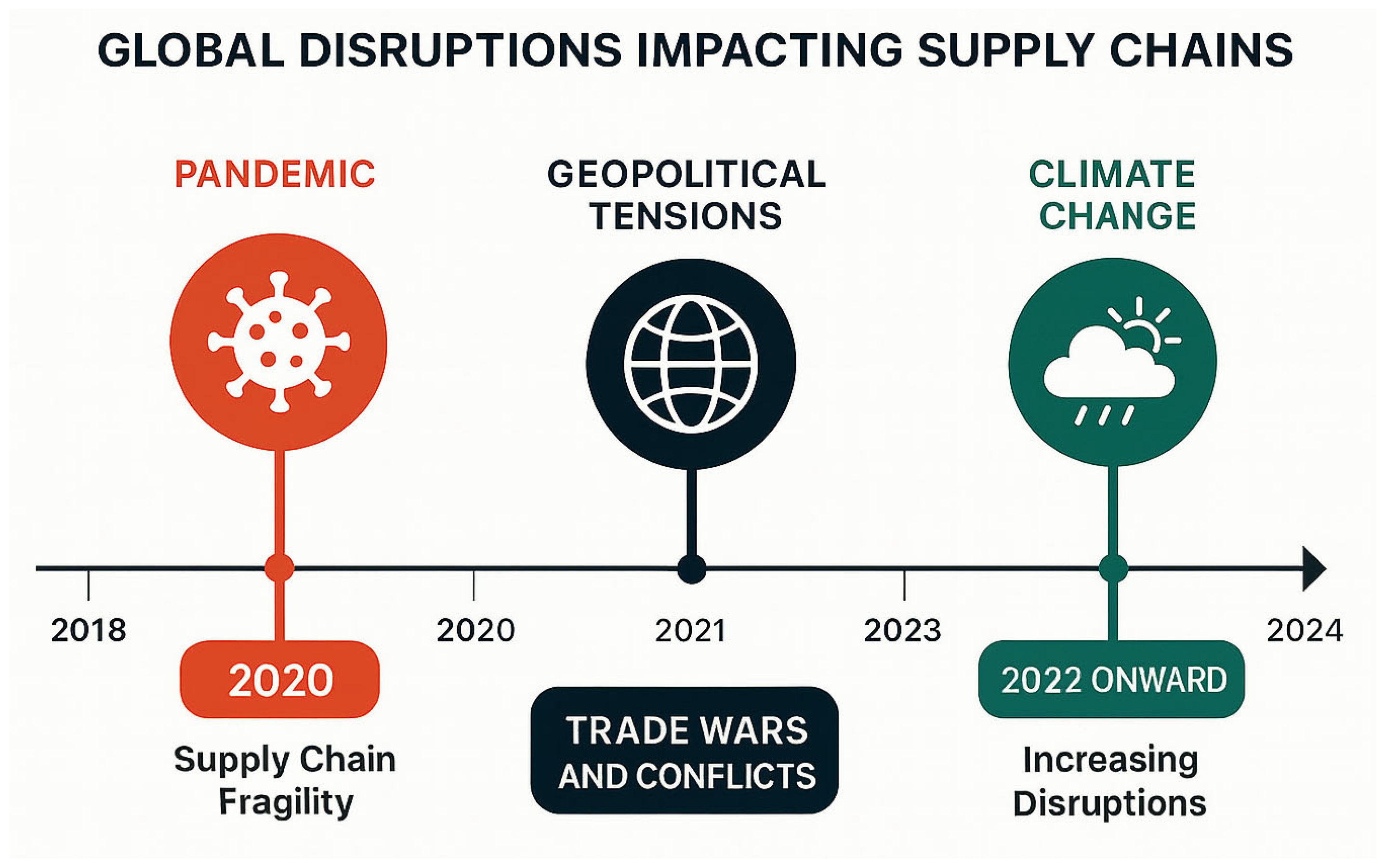

Recent global events have exposed significant fragilities. The animal health supply chain faces a unique set of challenges that differentiate it from other sectors.

First, regulatory complexity is immense. Products often require separate approvals for different species and geographic regions, creating bottlenecks. Second, many biological products, like vaccines, have stringent cold chain requirements. A temperature excursion during transit can render an entire shipment useless. Third, the market has a high volume of small-quantity, high-variety orders, especially for companion animal products, making logistics optimization difficult.

Perhaps the most pressing issue is the just-in-time inventory model adopted by many distributors and clinics. While efficient in stable times, this model offers little buffer against sudden demand spikes or supply shocks. For instance, during the early stages of a disease outbreak, demand for specific vaccines can skyrocket overnight, depleting stocks before production can ramp up. According to a report by the Animal Health Institute, over 60% of veterinary clinics reported significant shortages of at least one critical product in a recent 12-month period (来源: Animal Health Institute Supply Chain Survey).

# A Comparative Analysis: Traditional vs. Resilient Supply Chain Models

To understand the path forward, it is useful to contrast the traditional approach with a more resilient model. The following table highlights key differences.

| Feature | Traditional Model | Resilient Model |

|---|---|---|

| INVENTORY STRATEGY | Just-in-time (JIT), minimal safety stock | Just-in-case (JIC), strategic buffer stock for critical items |

| SUPPLIER RELATIONSHIPS | Transactional, cost-focused, single-source for key items | Collaborative, long-term partnerships, multi-sourcing for critical items |

| DATA UTILIZATION | Reactive, siloed data within departments | Proactive, integrated data platforms with predictive analytics |

| RISK MANAGEMENT | Ad-hoc response to disruptions | Continuous risk assessment with predefined contingency plans |

| TRANSPARENCY | Limited visibility beyond immediate suppliers/customers | End-to-end visibility from raw material to end-user |

# A 5-Step Action Plan for Veterinary Clinics and Farms

Building resilience does not have to start at the corporate level. Individual veterinary practices and farms can take concrete steps to secure their own supply lines. Here is a practical, five-step guide.

STEP 1: CONDUCT A CRITICAL PRODUCT AUDIT.

List every product you use and categorize it by criticality. Consider factors like: Is it life-saving? Are there few or no alternatives? How long can you operate without it? This audit forms the basis of all your planning.

STEP 2: DIVERSIFY YOUR SUPPLIER BASE.

For your most critical items, identify and qualify at least one alternative supplier. This might mean sourcing a generic equivalent or establishing a relationship with a different distributor. Do not wait for a shortage to begin this process.

STEP 3: ADJUST YOUR INVENTORY POLICY.

Based on your audit, move from a pure JIT model for critical items. Calculate a safety stock level that would cover you through a reasonable disruption lead time, such as 4-8 weeks. This requires allocating capital to inventory, but it is an insurance policy.

STEP 4: IMPLEMENT DIGITAL INVENTORY TRACKING.

Replace manual spreadsheets and guesswork with inventory management software. These systems can track lot numbers, expiration dates, and usage rates, and can even automate reordering points based on your preset rules.

STEP 5: BUILD A NETWORK WITH PEERS.

Join local or online professional groups. Sharing information about local shortages, reliable suppliers, or compounding pharmacies can be invaluable during a crisis. Collective intelligence is a powerful risk mitigation tool.

COMMON MISSTEP TO AVOID:

A frequent mistake is focusing inventory buffers only on high-cost items. In our team’s experience consulting with agricultural co-ops, the most disruptive shortages are often low-cost, commoditized items like certain antibiotics or sterile gloves. Their low cost leads to complacency in stocking, but their absence can halt procedures entirely. Always buffer based on criticality, not just price.

# The Role of Technology and Data in Modernizing the Chain

Technology is the great enabler of supply chain resilience. Internet of Things (IoT) sensors provide real-time monitoring of temperature and location for sensitive shipments. Blockchain technology, while still emerging, offers a tamper-proof ledger for tracking a product’s journey, enhancing authenticity and recall management. Most impactful, however, is the use of advanced analytics and artificial intelligence.

Predictive analytics can model demand patterns based on historical data, seasonal disease trends, and even weather forecasts. This allows for smarter production planning and inventory positioning. For example, AI models can analyze news reports and social media chatter in a region to provide early warning of potential disease outbreaks, allowing the supply chain to prepare. A study published in the journal *Nature* demonstrated that AI-driven models could predict certain livestock disease outbreaks with over 80% accuracy two months in advance (来源: Nature Communications, “Predictive Analytics for Animal Disease”).

# Global Regulations and Their Impact on Logistics

The animal health sector is one of the most heavily regulated. Navigating this landscape is a core function of the supply chain. Products must comply with regulations set by bodies like the U.S. FDA’s Center for Veterinary Medicine (CVM), the European Medicines Agency (EMA), and countless other national authorities. These regulations govern every aspect: manufacturing practices (GMP), labeling, storage conditions, and residue tolerances in food-producing animals.

This regulatory patchwork directly impacts logistics. A product approved in the EU may not be approved in Asia, requiring separate production runs or complex labeling changes. Furthermore, customs clearance for animal health products can be slow and documentation-intensive. Companies that invest in dedicated regulatory affairs expertise within their supply chain teams can navigate these hurdles more efficiently, avoiding costly delays at borders.

# Building a Future-Proof Animal Health Supply Chain

Looking ahead, resilience will be defined by agility and sustainability. The concept of “regionalization” is gaining traction—building production capacity and supplier networks across different geographic regions to mitigate the risk of a localized disaster shutting down global supply. Sustainability is also moving from a nice-to-have to a must-have, with stakeholders demanding greener logistics and ethical sourcing of materials.

Ultimately, a future-proof animal health supply chain is transparent, collaborative, and intelligent. It leverages data not just for internal efficiency but for the collective good of the industry, ensuring that veterinarians and farmers have the tools they need to safeguard animal health, which in turn protects human health and our global food systems.

FINAL CHECKLIST FOR SUPPLY CHAIN RESILIENCE:

– IDENTIFY AND LIST ALL CRITICAL PRODUCTS BY NAME AND SUPPLIER.

– SECURE AT LEAST ONE ALTERNATIVE SOURCE FOR EACH CRITICAL ITEM.

– ESTABLISH A FORMAL, WRITTEN SAFETY STOCK POLICY FOR PRIORITY ITEMS.

– DEPLOY A DIGITAL SYSTEM TO MANAGE INVENTORY AND EXPIRATIONS.

– DEVELOP A COMMUNICATION PROTOCOL FOR INTERNAL STAFF AND EXTERNAL CUSTOMERS DURING SHORTAGES.

– CONDUCT A BI-ANNUAL REVIEW OF YOUR SUPPLY CHAIN RISK ASSESSMENT.

– FOSTER RELATIONSHIPS WITH OTHER LOCAL PRACTICES OR FARMS FOR INFORMATION SHARING.