# The Ultimate Guide to Building a High-Impact Supply Chain Center of Excellence

Imagine your supply chain operating like a finely tuned orchestra. Every department, from procurement to logistics, plays in perfect harmony. Disruptions are anticipated and managed. Innovation is constant. This is the promise of a mature supply chain center of excellence. But for many organizations, the concept remains vague and its execution elusive.

This guide cuts through the noise. We will define what a supply chain center of excellence truly is, outline its undeniable benefits, and provide a concrete, step-by-step blueprint for building one that delivers measurable value. Whether you are starting from scratch or looking to revitalize an existing team, this is your roadmap.

UNDERSTANDING THE SUPPLY CHAIN CENTER OF EXCELLENCE

A supply chain center of excellence is not just another department or a rebranded analytics team. It is a dedicated, cross-functional hub of expertise designed to drive continuous improvement, standardization, and strategic innovation across the entire supply chain network. Think of it as the brain and nervous system of your operations.

Its primary mission is to move the supply chain from a reactive, cost-centric function to a proactive, value-driving engine for the business. A true supply chain center of excellence focuses on capability building, process optimization, technology governance, and data-driven decision-making for the entire organization.

KEY BENEFITS: WHY INVEST THE EFFORT?

The investment in establishing a supply chain center of excellence pays dividends across the board. Organizations with such centralized expertise report significant advantages.

First, they achieve superior cost management through standardized processes and consolidated buying power. Second, they build remarkable resilience. By centralizing risk assessment and developing playbooks, they can navigate disruptions more effectively. Third, innovation accelerates. The CoE can pilot new technologies, like AI-driven demand sensing or blockchain for traceability, in a controlled environment before enterprise-wide rollout.

According to a Deloitte study, companies with advanced supply chain capabilities, often housed in a CoE, report 2.3 times higher EBITDA (earnings before interest, taxes, depreciation, and amortization) than their peers. Furthermore, Gartner notes that by 2025, 80% of organizations seeking to scale digital supply chain initiatives will require a center of excellence to achieve value (source: Gartner).

From my experience consulting with global manufacturers, the most successful centers are those that secure early, visible wins. This builds credibility and secures ongoing executive sponsorship, which is the lifeblood of any CoE.

CORE PILLARS OF A SUCCESSFUL SUPPLY CHAIN CENTER OF EXCELLENCE

A robust supply chain center of excellence rests on four interconnected pillars. Neglecting any one can undermine the entire structure.

1. GOVERNANCE AND STRATEGY: This pillar defines the CoE’s mission, governance model, and how it aligns with corporate strategy. It establishes decision-rights and project prioritization frameworks.

2. PROCESS STANDARDIZATION: Here, the focus is on identifying, documenting, and optimizing end-to-end processes. The goal is to eliminate wasteful variations and create a single, best-practice way of working.

3. TECHNOLOGY AND ANALYTICS: This pillar manages the supply chain technology stack, ensures data integrity, and develops advanced analytical models. The CoE acts as the translator between business needs and IT solutions.

4. TALENT AND CHANGE MANAGEMENT: Perhaps the most critical, this pillar focuses on building skills, fostering a culture of continuous improvement, and managing the human side of transformation initiatives.

COMMON PITFALLS AND HOW TO AVOID THEM

Many well-intentioned supply chain center of excellence initiatives fail. Being aware of these traps is your first defense.

A major pitfall is creating an “ivory tower” team disconnected from day-to-day operations. The CoE must collaborate, not dictate. Another common error is focusing solely on cost-cutting, which can stifle innovation and long-term value creation. Finally, underestimating the change management effort is a recipe for resistance. People and processes must be nurtured through the transition.

WARNING: DO NOT launch your supply chain center of excellence as a top-down mandate without clear communication of its “what’s in it for me” for operational teams. This will guarantee friction and slow adoption. Start with collaborative pilots instead.

BUILDING YOUR SUPPLY CHAIN CENTER OF EXCELLENCE: A 5-STEP BLUEPOINT

Here is a practical, phased approach to building your own high-impact supply chain center of excellence.

STEP 1: DEFINE SCOPE AND SECURE SPONSORSHIP

Begin by clearly articulating the scope. Will your CoE cover the entire supply chain or focus on a specific domain like planning or logistics? Secure a C-level sponsor who understands the strategic value and can champion the initiative, securing necessary budget and resources.

STEP 2: ASSESS CURRENT CAPABILITIES AND PAIN POINTS

Conduct an honest assessment of your current supply chain maturity. Identify key pain points, skill gaps, and technology shortcomings. This diagnostic will form the baseline and help prioritize the CoE’s initial projects.

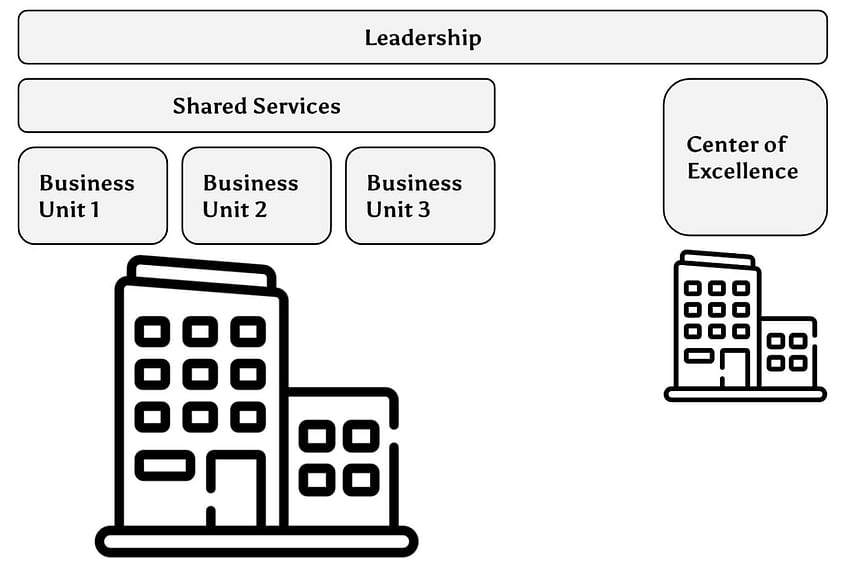

STEP 3: DESIGN THE OPERATING MODEL

Decide on the CoE’s structure. Will it be a centralized physical team, a virtual network of experts, or a hybrid? Define roles, responsibilities, and its interaction model with business units. Crucially, establish key performance indicators (KPIs) tied to business outcomes, not just activity metrics.

STEP 4: STAFF WITH THE RIGHT TALENT

Populate your supply chain center of excellence with a mix of talent: seasoned subject matter experts, data scientists, process engineers, and change managers. Look for individuals who are not only technically proficient but also skilled influencers and communicators.

STEP 5: EXECUTE A ROADMAP WITH QUICK WINS

Develop a 12-18 month roadmap. Balance long-term strategic projects (e.g., implementing a control tower) with short-term “quick wins” that demonstrate tangible value. For example, optimizing a carrier routing guide to reduce freight costs by 5% within a quarter builds immediate credibility.

CHOOSING THE RIGHT FOCUS: PLANNING VS. EXECUTION COE

Not all centers of excellence are the same. Your strategic goals should dictate the primary focus. The table below contrasts two common models.

| Aspect | Planning-Focused CoE | Execution-Focused CoE |

|---|---|---|

| PRIMARY GOAL | Improve forecast accuracy, inventory optimization, and S&OP/IBP processes. | Enhance logistics efficiency, warehouse operations, and transportation management. |

| KEY METRICS | Forecast Bias, Inventory Turns, Service Level. | On-Time In-Full (OTIF), Cost per Unit Shipped, Warehouse Capacity Utilization. |

| TYPICAL TOOLS | Advanced Planning Systems (APS), Demand Sensing Software. | Transportation Management Systems (TMS), Warehouse Management Systems (WMS). |

| BEST FOR ORGANIZATIONS THAT… | Struggle with demand volatility and carrying excess inventory. | Face high logistics costs and complex physical distribution networks. |

MEASURING SUCCESS AND SCALING IMPACT

The success of your supply chain center of excellence must be measured by business outcomes, not activity. Track a balanced scorecard that includes financial metrics (e.g., total supply chain cost reduction), operational metrics (e.g., perfect order rate), and strategic metrics (e.g., speed of innovation adoption).

As the CoE matures, its role should evolve from direct project execution to enabling and coaching business units. It becomes the curator of best practices and the incubator for next-generation supply chain capabilities, ensuring the entire organization continues to advance.

FINAL CHECKLIST FOR LAUNCHING YOUR SUPPLY CHAIN CENTER OF EXCELLENCE

Before you begin, ensure you can affirm the following points. This checklist serves as your final gate for a successful launch.

– Executive sponsorship is secured and actively engaged.

– The initial scope is clearly defined and communicated.

– A baseline assessment of current capabilities is complete.

– The operating model and governance rules are documented.

– Key roles are filled with a blend of technical and soft skills.

– A 12-month roadmap with defined quick-win projects is in place.

– Success metrics are aligned with overall business KPIs.

– A change management and communication plan is ready.

Building a transformative supply chain center of excellence is a journey. It requires patience, persistence, and a relentless focus on creating and demonstrating value. By following this structured approach, you can establish a powerful engine that not only optimizes today’s operations but also future-proofs your supply chain for the challenges and opportunities ahead.