# The Ultimate Guide to Boost Chain Line: 5 Expert Strategies for Unmatched Efficiency

If you are searching for ways to optimize your production or logistics, you have likely encountered the term boost chain line. This concept is not just a buzzword. It represents a fundamental approach to enhancing the flow, speed, and reliability of sequential operations. Whether in manufacturing, software development, or supply chain management, a well-implemented boost chain line strategy can be the difference between stagnation and breakthrough growth.

This guide will demystify the boost chain line. We will explore its core principles, practical applications, and provide you with a actionable blueprint. Our goal is to move beyond theory and give you the tools to identify bottlenecks, implement solutions, and measure real-world impact. Let us begin by understanding what we are truly dealing with.

## What is a Boost Chain Line? Defining the Core Concept

At its heart, a boost chain line refers to a series of interconnected processes or stages where performance improvements in one link directly and positively amplify the output of the entire chain. Think of it as a production line, but with a specific focus on injecting efficiency boosts at critical points.

The key differentiator from simple process improvement is the chain reaction effect. A boost in one area is designed to create multiplicative gains downstream, rather than just additive ones. For example, in a software deployment pipeline (a classic modern boost chain line), automating code testing not only speeds up the testing phase but also reduces bugs in later stages, which in turn accelerates deployment and improves final product quality. The entire line receives a boost.

## The Critical Components of an Effective Boost Chain Line

To build or improve a boost chain line, you must focus on several interdependent components. Ignoring any one of them can limit your overall gains.

VISIBILITY AND MONITORING: You cannot boost what you cannot see. Comprehensive data collection at every stage is non-negotiable. This means tracking time, cost, error rates, and throughput.

INTERDEPENDENCY ANALYSIS: Understanding how each stage feeds into the next is crucial. A slowdown in Stage A might cause a bigger bottleneck in Stage C. Tools like value stream mapping are essential here.

FLEXIBILITY AND ADAPTABILITY: A rigid chain will break. Your boost chain line must have built-in mechanisms to adapt to fluctuations in demand, resource availability, or unexpected disruptions.

FEEDBACK LOOPS: Information must flow backwards as well as forwards. Performance data from the end of the line should inform adjustments at the beginning, creating a cycle of continuous improvement.

## Common Boost Chain Line Applications: From Factory Floor to Digital World

The principle of the boost chain line is universally applicable. Here are some of the most impactful real-world applications.

IN MANUFACTURING: This is the traditional home of line optimization. Implementing robotic automation at a key assembly stage can boost the entire production line’s output. A study by the International Federation of Robotics found that robot density in manufacturing reached a new global average of 151 robots per 10,000 employees, a key driver in boosting production chain efficiency (来源: IFR World Robotics Report).

IN SOFTWARE DEVOPS: The CI/CD (Continuous Integration/Continuous Deployment) pipeline is a digital boost chain line. Automating the build, test, and deployment stages creates a seamless, fast, and reliable flow from code commit to live product.

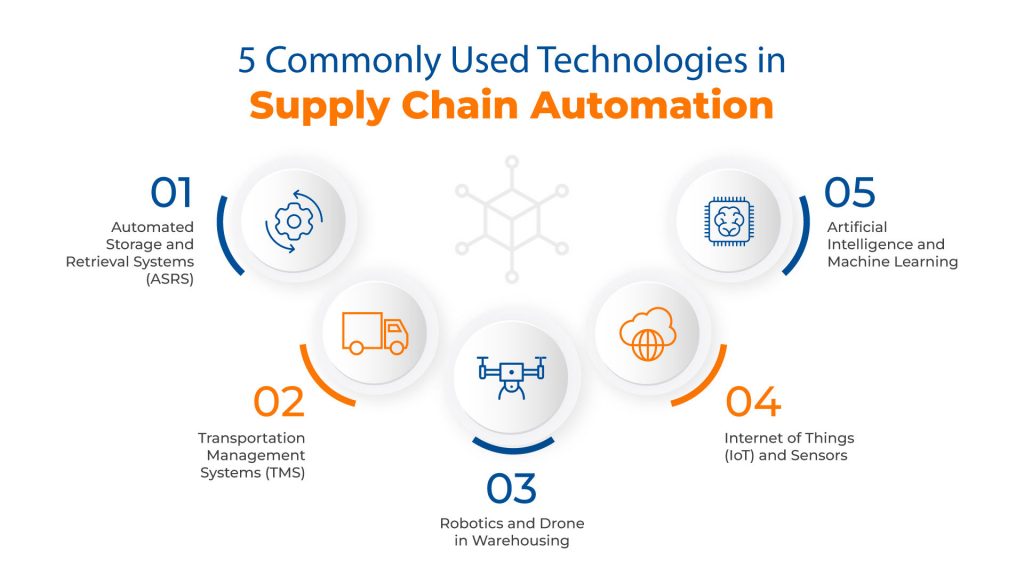

IN SUPPLY CHAIN AND LOGISTICS: Here, the boost chain line might involve integrating real-time GPS tracking with automated warehouse sorting systems. A boost in information flow accuracy directly boosts the physical flow of goods, reducing delays and costs.

To illustrate the difference between a traditional and a boosted approach, consider this comparison in a packaging and shipping context.

| Process Stage | Traditional Chain Line | Boosted Chain Line |

|---|---|---|

| Order Picking | Paper lists, manual search | Handheld scanners with optimal route algorithms |

| Quality Check | Batch sampling at end of line | Computer vision system scanning every item on conveyor |

| Packaging | Fixed box sizes, manual taping | On-demand box sizing machines, automated sealing |

| Labeling & Dispatch | Manual weighing and label printing | Automated weight capture, integrated label printing, and carrier API dispatch |

| Overall Impact | Higher error rate, slower throughput, variable cost | Lower errors, faster throughput, predictable cost and time |

## A 5-Step Action Plan to Implement Your Boost Chain Line Strategy

Theory is useful, but action creates results. Follow this five-step plan to start boosting your own chain line.

STEP 1: MAP YOUR CURRENT VALUE STREAM. Document every single step in your process, from initiation to delivery. Include time spent, wait times, and handoffs. You will be surprised where time is lost.

STEP 2: IDENTIFY THE PRIMARY CONSTRAINT. Use the data from your map. Find the single stage that is most limiting your overall throughput. This is your bottleneck, and it is your first priority for a boost.

STEP 3: DESIGN AND APPLY A TARGETED BOOST. Do not try to improve everything at once. Focus all initial efforts on alleviating the primary constraint. This could be a technology upgrade, a procedure change, or a resource reallocation.

STEP 4: MEASURE THE DOWNSTREAM EFFECT. After implementing your boost, measure the performance of the stages that come AFTER the bottleneck. Did their throughput improve? Did wait times decrease? This confirms the chain reaction effect.

STEP 5: ITERATE AND SCALE. Once the first bottleneck is resolved, a new one will often emerge. Repeat the process. This cycle of identify-boost-measure is the engine of continuous boost chain line optimization.

Based on my experience consulting with mid-sized manufacturers, the most common mistake in step 2 is misidentifying the bottleneck because teams measure activity instead of output. A machine might be running constantly (high activity) but have a high reject rate, making it the true constraint despite appearing busy.

## Pitfalls and Common Mistakes to Avoid

As you embark on your boost chain line journey, be wary of these frequent errors.

A common mistake is optimizing a stage in isolation. Boosting the speed of a stage that feeds into a slower stage only creates a larger pile of work-in-progress before the bottleneck. You increase local efficiency but harm overall flow.

Another critical error is neglecting human factors. A new system or process is only as good as the people operating it. Failure to train staff and secure their buy-in will undermine any technological boost. Research from Gartner highlights that through 2025, 70% of supply chain digital transformation initiatives will face stalled progress due to a lack of change management (来源: Gartner).

Finally, do not fall for the “set and forget” trap. A boost chain line is not a one-time project. It is a dynamic system that requires ongoing monitoring and adjustment as internal and external conditions change.

## Your Boost Chain Line Implementation Checklist

To ensure you have covered all bases, use this practical checklist before and during your implementation.

Complete a full value stream map of the existing process.

Collect quantitative data for time, cost, and error rate at each stage.

Clearly identify and validate the primary bottleneck constraint.

Design a boost solution focused solely on alleviating that bottleneck.

Calculate the expected ROI or performance gain of the boost.

Plan for staff training and change management communications.

Implement the boost and monitor the bottleneck’s performance.

Measure the impact on downstream stages for chain reaction confirmation.

Document the results and lessons learned.

Schedule a review to identify the next constraint and repeat the cycle.

By methodically applying the principles and steps outlined in this guide, you can transform your linear processes into powerful, responsive, and efficient boost chain lines. The journey requires focus and persistence, but the rewards in productivity, quality, and competitive advantage are substantial. Start mapping your first chain today.