# The Ultimate Guide to Automotive Supply Chain Collaboration: 7 Logistics Improvements That Drive Profit

The modern automotive industry is a symphony of complexity. A single vehicle comprises thousands of parts sourced from a global network of suppliers. When this symphony is out of tune, the result is delayed production, excess inventory, and frustrated customers. This is why mastering automotive supply chain collaboration logistics improvements is no longer a luxury. It is a fundamental requirement for survival and growth. True collaboration moves beyond simple data exchange. It is about creating a connected, transparent, and agile ecosystem where every partner works from a single source of truth. This guide dives deep into the strategic and tactical improvements that transform your logistics from a cost center into a competitive weapon.

We will explore the core challenges, actionable solutions, and the tangible benefits of a truly collaborative automotive supply chain. The journey from fragmented operations to seamless integration is paved with specific logistics improvements.

UNDERSTANDING THE COLLABORATION IMPERATIVE

Historically, automotive supply chains operated on a push model. OEMs set forecasts, and suppliers scrambled to meet them, often leading to the infamous bullwhip effect. Small fluctuations in end-demand cause massive swings in orders upstream. Collaboration flips this script. It establishes a pull-based model driven by real-time demand and shared visibility. The goal is to create a resilient network capable of weathering disruptions, from geopolitical events to port congestion. According to a study by McKinsey, companies with highly collaborative supply chains can reduce inventory levels by up to 30% and improve service levels by a similar margin. (来源: McKinsey & Company). This is the power of working as one.

KEY LOGISTICS IMPROVEMENTS THROUGH COLLABORATION

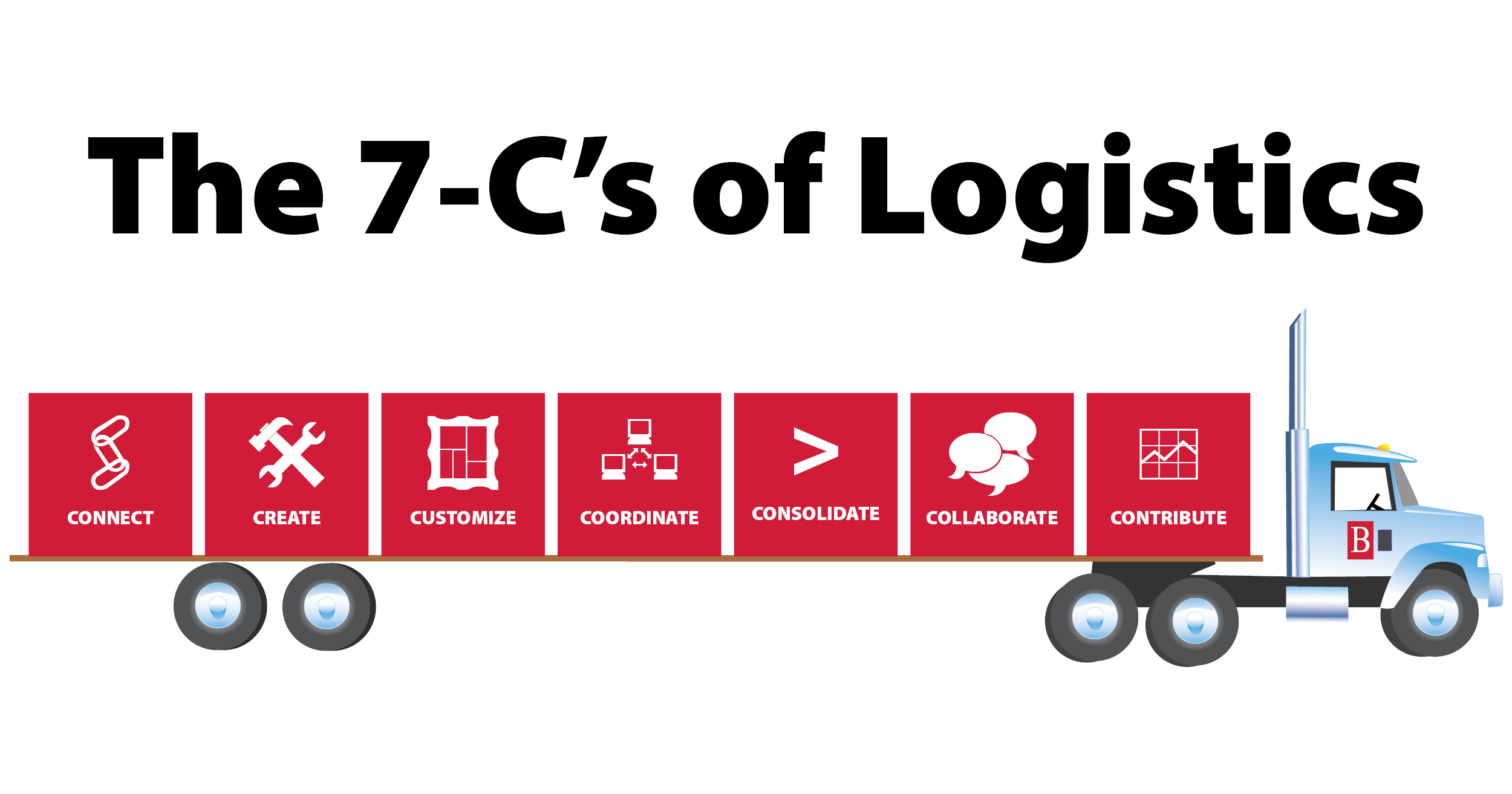

Let us break down the seven most impactful areas where collaboration drives concrete logistics improvements.

1. PREDICTIVE DEMAND PLANNING AND FORECAST SHARING

The foundation of all improvement is a shared view of the future. Instead of OEMs sending static, often inaccurate forecasts, collaborative platforms enable dynamic, multi-tier forecasting. Suppliers gain access to real-time sales data, production schedules, and even market intelligence. This allows them to plan capacity, raw material procurement, and labor more accurately. The result is a dramatic reduction in both shortages and overstock situations.

2. REAL-TIME INVENTORY VISIBILITY ACROSS TIERS

Not knowing where your parts are is a recipe for disaster. Collaborative logistics demand end-to-end visibility. This means implementing technologies like IoT sensors, RFID tags, and blockchain-enabled trackers that provide a live view of inventory at the supplier warehouse, in transit, at cross-docks, and at the assembly plant. All partners see the same data. This eliminates blind spots, reduces safety stock needs, and enables proactive exception management. For example, if a shipment is delayed at a port, both the OEM and the next-tier supplier are alerted simultaneously and can adjust plans.

3. COORDINATED TRANSPORTATION AND MILK RUN OPTIMIZATION

Empty trucks and fragmented deliveries are a massive source of waste. Collaboration allows for the consolidation of shipments from multiple suppliers serving the same manufacturing plant or region. Implementing optimized “milk runs”—where a single truck collects parts from several suppliers on a fixed schedule—reduces transportation costs, carbon footprint, and dock congestion. A shared transportation management system (TMS) among partners is key to planning these efficient routes.

4. SYNCHRONIZED PRODUCTION AND SEQUENCED DELIVERY

Moving from bulk deliveries to just-in-sequence (JIS) logistics is the pinnacle of collaboration. In a JIS model, parts arrive at the assembly line in the exact order they will be installed, often within a window of minutes. This requires flawless synchronization between the supplier’s production schedule and the OEM’s assembly line sequence. It eliminates line-side inventory and handling, but it demands ultra-reliable data exchange and joint contingency planning. The savings in floor space and labor are substantial.

5. COLLABORATIVE WAREHOUSE AND YARD MANAGEMENT

The logistics handoff points—yards and warehouses—are critical. Collaborative yard management systems (YMS) allow suppliers to book dock appointments digitally, receive real-time updates on gate wait times, and get instant alerts when their trailer is spotted. This smooths the flow of goods, reduces detention and demurrage charges, and improves asset utilization for carriers. It turns a chaotic yard into a predictable, efficient hub.

6. JOINT CONTINUITY PLANNING AND RISK MITIGATION

Modern supply chains face constant risk. Collaborative partners do not hide problems; they solve them together. This involves creating joint business continuity plans, conducting stress-test simulations, and pre-qualifying alternative suppliers or logistics routes as a consortium. Sharing risk intelligence, such as regional weather events or political instability, allows the entire network to brace for impact and recover faster.

7. PERFORMANCE MANAGEMENT WITH SHARED KPIs

You cannot improve what you do not measure collectively. Moving beyond one-sided scorecards, collaborative networks establish a set of shared Key Performance Indicators (KPIs). These might include On-Time In-Full (OTIF) rates, lead time variability, quality incident resolution time, or carbon emissions per part. Regular joint business reviews focused on these shared metrics foster a culture of continuous, mutual improvement.

TECHNOLOGY ENABLERS: A COMPARISON

Choosing the right technology platform is crucial. Here is a comparison of two primary approaches:

| Feature / Aspect | Traditional EDI / Portal Systems | Modern Cloud-Based Collaboration Platforms |

|---|---|---|

| DATA EXCHANGE | Structured, batch-based (e.g., daily ASNs). Slow update cycles. | Real-time, event-driven. Continuous flow of data from IoT, ERP, TMS. |

| VISIBILITY | Limited to transactional documents (PO, ASN). Siloed data. | End-to-end, multi-tier visibility on a single dashboard. Map-based tracking. |

| INTEGRATION EASE | Complex, point-to-point integrations. High cost for adding partners. | API-first architecture. Easier, faster onboarding of suppliers of all sizes. |

| ANALYTICS & INSIGHTS | Basic reporting. Historical data only. | Predictive analytics, AI-driven insights, and prescriptive recommendations. |

| COLLABORATION TOOLS | Email and phone for exception management. | Built-in messaging, workflow automation, and joint task management. |

IMPLEMENTATION ROADMAP: A 5-STEP GUIDE

Based on my experience consulting with tier-1 suppliers, a successful rollout follows a phased approach.

STEP 1: INTERNAL ALIGNMENT AND CHAMPION IDENTIFICATION

Secure executive sponsorship. Form a cross-functional team with members from procurement, logistics, IT, and operations. Define your primary pain points and desired outcomes. Are you targeting inventory reduction, resilience, or cost savings?

STEP 2: SELECT AND PILOT WITH STRATEGIC PARTNERS

Do not boil the ocean. Choose 2-3 trusted, technologically capable suppliers for a pilot program. Focus on a specific process, like real-time shipment tracking or forecast sharing. Use this pilot to test technology, refine processes, and build a success story.

STEP 3: INVEST IN THE CORE TECHNOLOGY PLATFORM

Select a platform based on the comparison above. Prioritize user-friendliness, scalability, and strong API capabilities. Ensure it can connect to your core ERP and WMS systems.

STEP 4: DEVELOP CLEAR PROCESSES AND GOVERNANCE

Technology is an enabler, not a solution. Document new collaborative workflows. Define roles, responsibilities, and escalation paths. Establish the shared KPIs and schedule regular performance reviews.

STEP 5: PHASED ROLLOUT AND CHANGE MANAGEMENT

Onboard suppliers in waves, starting with the most critical. Provide extensive training and support. Celebrate early wins to build momentum. Remember, this is a cultural shift as much as a technical one.

COMMON PITFALLS TO AVOID

WARNING: A collaborative initiative can fail if you fall into these traps.

One of the biggest mistakes is treating collaboration as a purely IT project. The technology is secondary to the relationship and process redesign. Another critical error is imposing a solution on suppliers without their input. This creates resistance. Collaboration must be a two-way street with clear mutual benefits. Finally, do not underestimate data quality. Garbage in, garbage out. Inconsistent part numbers, unit measures, or location codes will cripple any system. Start with a data cleansing project.

THE BOTTOM LINE

Investing in automotive supply chain collaboration logistics improvements is a strategic imperative. The benefits are clear: a study by the Association for Supply Chain Management (ASCM) found that companies with high levels of supply chain collaboration achieve a 50% higher gross margin growth than their peers. (来源: Association for Supply Chain Management). Our team has seen firsthand how moving from a adversarial, transactional relationship to a true partnership unlocks value that neither party could achieve alone. It builds a supply chain that is not just efficient, but intelligent, responsive, and resilient.

Are you ready to start your collaboration journey? Begin by assessing your current state against this practical checklist.

CHECKLIST FOR AUTOMOTIVE SUPPLY CHAIN COLLABORATION

– Executive sponsorship and a dedicated cross-functional team are in place.

– Primary pain points and target KPIs for improvement are clearly defined.

– A pilot program with 2-3 key suppliers has been planned.

– A technology platform enabling real-time, multi-tier data exchange has been evaluated.

– Internal and joint processes for new workflows have been documented.

– A data governance plan to ensure master data quality is established.

– A phased supplier onboarding and training program is ready.

– A framework for regular joint business reviews with shared metrics is created.

– A risk mitigation and continuity planning process with partners is initiated.

– A communication plan to share successes and drive cultural adoption is developed.