# The Ultimate Guide to AI Supply Chain Grimmelman: 5 Steps to Transform Your Logistics

The term AI supply chain Grimmelman is gaining traction among logistics professionals and business leaders. But what does it actually mean? In essence, it refers to the application of advanced artificial intelligence, specifically the analytical and predictive frameworks often associated with sophisticated data science, to solve complex supply chain problems. While “Grimmelman” might evoke a sense of rigorous, almost legalistic analysis, in this context, it symbolizes a methodical, deep-dive approach to supply chain optimization using AI tools. This guide will demystify the concept and provide a practical roadmap for implementation.

At its core, an AI-driven supply chain moves beyond basic automation. It involves systems that can learn, predict, and prescribe actions. Imagine a network that not only tracks inventory but also forecasts regional demand spikes, prescribes optimal rerouting during disruptions, and negotiates carrier rates autonomously. This is the promise of modern supply chain AI. The global AI in supply chain market is projected to grow from USD 5.6 billion in 2020 to USD 21.8 billion by 2027, highlighting the massive shift underway (来源: MarketsandMarkets报告).

## Understanding the Grimmelman Approach to Supply Chain AI

The Grimmelman angle emphasizes scrutiny and structured problem-solving. It is not about throwing AI at every process. Instead, it is about identifying the most critical, high-impact areas where machine learning and predictive analytics can deliver definitive returns. This approach asks tough questions: Where is our data flawed? What assumptions are we making that an algorithm could challenge? Which inefficiencies have we simply accepted as “the cost of doing business”?

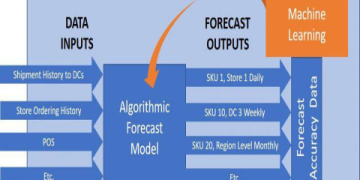

This mindset shifts the focus from technology for technology’s sake to strategic outcomes. For instance, rather than just implementing a demand forecasting tool, the Grimmelman method would involve a deep audit of historical data quality, market variables, and the cost of both overstock and stockouts to build a model that truly minimizes financial risk.

## Key Benefits of Implementing an AI-Powered Supply Chain

Adopting a sophisticated AI supply chain strategy yields transformative benefits. First, predictive accuracy soars. AI models analyze vast datasets—from weather patterns to social media trends—to forecast demand with unprecedented precision. This directly reduces inventory carrying costs and mitigates stockout scenarios.

Second, resilience becomes embedded. AI systems simulate countless “what-if” scenarios, from port closures to supplier bankruptcies, allowing companies to build contingency plans proactively. Third, operational costs plummet through optimized routing, automated warehouse operations, and dynamic procurement. A study by McKinsey found that AI-enabled supply-chain management can reduce forecasting errors by 20-50%, lost sales by up to 65%, and inventory reductions of 20-50% (来源: McKinsey & Company).

## AI Supply Chain Software: A Comparative Analysis

Choosing the right platform is crucial. Not all AI supply chain solutions are created equal. Some focus on specific niches like transportation management, while others offer end-to-end suite capabilities. The table below contrasts two broad categories of solutions relevant to an AI supply chain Grimmelman implementation.

| Feature / Aspect | Best-of-Breed AI Point Solutions | Integrated AI Suite Platforms |

|---|---|---|

| PRIMARY FOCUS | Deep functionality in one area (e.g., demand forecasting, warehouse robotics) | Holistic integration across planning, execution, and logistics |

| IMPLEMENTATION SPEED | Faster to deploy for a specific pain point | Longer, more complex deployment but wider impact |

| DATA UNIFICATION CHALLENGE | High – requires integration with other systems | Lower – designed to work on a unified data model |

| BEST FOR | Companies targeting a single, acute bottleneck | Organizations seeking a comprehensive, long-term transformation |

| GRIMMELMAN ALIGNMENT | Excellent for a focused, analytical deep-dive into one domain | Aligns with a methodical overhaul of the entire supply chain logic |

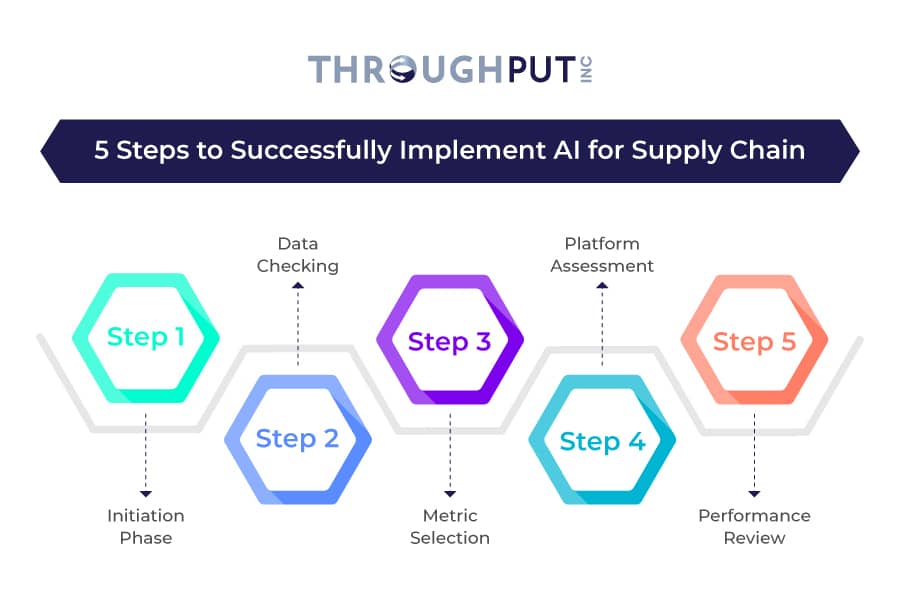

## A 5-Step Guide to Implementing Your AI Supply Chain Strategy

Embarking on this journey requires a disciplined plan. Here is a practical, five-step guide to implementing an AI supply chain Grimmelman project.

STEP 1: CONDUCT A DIAGNOSTIC AUDIT. Map your entire as-is supply chain process. Identify every data touchpoint, from supplier quotes to final delivery confirmation. Pinpoint exactly where decisions are made and what data informs them. This audit is the foundational “Grimmelman” step—it reveals the raw material for your AI models.

STEP 2: PRIORITIZE USE CASES WITH CLEAR ROI. Do not try to boil the ocean. Based on your audit, select one or two high-value, high-pain areas. Common starting points are demand forecasting accuracy, dynamic pricing for logistics, or predictive maintenance for fleet management. Define the specific key performance indicator you will improve, such as “reduce forecast error by 30%.”

STEP 3: PREPARE AND UNIFY YOUR DATA. AI is only as good as its data. This step involves cleaning historical data, integrating siloed data sources (ERP, WMS, TMS), and establishing ongoing data hygiene protocols. This is often the most time-consuming step but is non-negotiable.

STEP 4: SELECT AND DEPLOY THE SOLUTION. Based on your prioritized use case and the comparative analysis above, choose a tool or platform. Begin with a pilot project in a controlled environment or a single product line. Measure results rigorously against the KPIs defined in Step 2.

STEP 5: SCALE AND ITERATE. Upon successful pilot validation, develop a rollout plan to scale the solution across other product lines, regions, or functions. Establish a center of excellence to continuously refine models, incorporate new data sources, and identify the next use case for expansion.

## Common Pitfalls and How to Avoid Them

WARNING: A STRATEGY-FIRST MINDSET IS NON-NEGOTIABLE.

The most common failure point is starting with the technology instead of the business problem. Companies get enamored with a flashy AI demo and try to retrofit it into their operations. This leads to wasted investment and disillusionment. Always anchor your project in a specific, measurable business outcome.

Another major pitfall is underestimating data readiness. Teams assume their existing data is “good enough,” only to find that AI models produce garbage outputs due to poor data quality. Allocate sufficient time and resources for Step 3. Furthermore, neglecting change management can derail even the most technically perfect implementation. Employees must understand how AI will augment their roles, not replace them, and be trained accordingly.

From my experience consulting with mid-sized manufacturers, the teams that succeed are those that appoint a cross-functional leader—someone who understands both the operational pain points and the potential of the technology. They act as the translator between logistics managers and data scientists, ensuring the AI supply chain Grimmelman project stays focused on real-world value.

## Your AI Supply Chain Transformation Checklist

Before you launch your initiative, use this practical checklist to ensure you are on the right path. A methodical approach separates successful transformations from costly experiments.

IDENTIFY YOUR SINGLE BIGGEST SUPPLY CHAIN COST DRIVER.

SECURE EXECUTIVE SPONSORSHIP AND DEFINE A BUDGET.

ASSEMBLE A CROSS-FUNCTIONAL TEAM WITH OPERATIONS AND IT REPRESENTATIVES.

DOCUMENT THE SPECIFIC DECISION-MAKING PROCESS YOU WANT TO ENHANCE.

INVENTORY AND ASSESS THE QUALITY OF ALL RELEVANT DATA SOURCES.

SET A PRIMARY KPI FOR SUCCESS, TIED TO REVENUE OR COST.

START WITH A CONTROLLED PILOT, NOT A FULL-SCALE ROLLOUT.

PLAN FOR EMPLOYEE TRAINING AND COMMUNICATION FROM DAY ONE.

SCHEDULE REGULAR REVIEWS TO ASSESS MODEL PERFORMANCE AND DRIFT.

DEVELOP A ROADMAP FOR SCALING SUCCESSFUL PILOTS.

The journey toward an intelligent, resilient, and efficient supply chain is not a simple software installation. It is a strategic evolution. By adopting the rigorous, analytical mindset encapsulated by the AI supply chain Grimmelman concept, you can cut through the hype and build a logistics operation that is truly fit for the future. The competitive advantage gained by those who act now will be significant and long-lasting.