# Jordan Manufacturing: The Ultimate Guide to Modern Production and Supply Chain Excellence

The name Jordan Manufacturing carries significant weight in the industrial and supply chain sectors. For many, it represents a benchmark of quality, operational efficiency, and strategic sourcing. This comprehensive guide delves deep into what Jordan Manufacturing stands for today, exploring its core principles, the advanced technologies it employs, and the actionable strategies you can adopt to achieve similar levels of manufacturing excellence. Whether you are a procurement specialist, a supply chain manager, or a business owner, understanding this model is crucial for staying competitive.

At its heart, Jordan Manufacturing is not just a company name; it is a philosophy centered on precision engineering, lean operations, and robust supplier relationships. The modern manufacturing landscape is defined by volatility and complex global networks. Success hinges on the ability to adapt quickly, maintain quality under pressure, and optimize every link in the supply chain. This guide will break down these components, providing you with a clear roadmap.

## The Core Pillars of Modern Manufacturing Excellence

What separates top-tier manufacturers from the rest? It is a foundation built on several non-negotiable pillars. Jordan Manufacturing exemplifies these, which include a relentless focus on quality control, the implementation of lean manufacturing principles, and a strategic approach to supplier partnerships.

Quality control goes beyond final inspection. It is integrated into every stage of the production process, from raw material verification to in-process checks and final audit. This proactive approach minimizes waste and rework, saving significant costs. Lean manufacturing, a methodology pioneered by Toyota, focuses on eliminating waste—waste of time, materials, and effort. This creates a smoother, more efficient production flow.

Perhaps most critical is the supplier relationship. In a globalized economy, your manufacturing capability is only as strong as your weakest supplier. Building collaborative, transparent, and resilient partnerships is paramount. A 2022 report by McKinsey & Company highlighted that companies with mature supplier collaboration models achieved 20% faster time-to-market and 15% lower procurement costs (来源: McKinsey & Company).

## Technology Driving the Next Industrial Revolution

Modern manufacturing is inextricably linked with technology. The operations associated with a leader like Jordan Manufacturing are powered by a suite of advanced tools that create a “smart factory” environment. These technologies enable unprecedented levels of automation, data analysis, and predictive capability.

Key technologies include the Internet of Things (IoT), which connects machines and sensors to collect real-time performance data. Artificial Intelligence (AI) and machine learning algorithms analyze this data to predict equipment failures, optimize production schedules, and ensure quality consistency. Additive manufacturing, or 3D printing, allows for rapid prototyping and the production of complex, lightweight parts that are impossible with traditional methods.

According to a study by Deloitte, 86% of manufacturing executives believe that smart factory initiatives will be the main driver of manufacturing competitiveness in the next five years (来源: Deloitte Insights). This is not future speculation; it is the current operational standard for industry leaders.

## Software Solutions: The Central Nervous System

To manage the complexity of modern production and global supply chains, specialized manufacturing software is essential. This software acts as the central nervous system, integrating data from sales, inventory, production floors, and suppliers. Two of the most critical systems are Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES).

The table below contrasts these two vital systems:

| Feature | Enterprise Resource Planning (ERP) | Manufacturing Execution System (MES) |

|---|---|---|

| PRIMARY FOCUS | Business-wide resource planning and data integration (Finance, HR, Supply Chain). | Real-time monitoring and control of production operations on the shop floor. |

| DATA TYPE | Historical and transactional data (orders, invoices, financials). | Real-time operational data (machine status, production counts, quality metrics). |

| TIME HORIZON | Long-term and mid-term planning (weeks, months, years). | Short-term execution and control (seconds, minutes, hours, days). |

| KEY USERS | Executives, Finance, Procurement, Sales. | Production Supervisors, Floor Managers, Quality Technicians. |

| MAIN BENEFIT | Improved business visibility and streamlined cross-departmental processes. | Increased production efficiency, reduced downtime, and guaranteed quality traceability. |

For a seamless operation, these systems must be integrated. An ERP might tell you what to make and when, but the MES tells you how it is being made right now and alerts you to any issues.

## A 5-Step Guide to Optimizing Your Production Line

Inspired by the efficiency seen in leading manufacturing operations, here is a practical, five-step guide you can implement to optimize your own production line.

STEP 1: CONDUCT A VALUE STREAM MAPPING EXERCISE. Map every step in your production process, from order receipt to shipment. Identify each action as either value-adding, non-value-adding but necessary, or pure waste. This visual map is your baseline for improvement.

STEP 2: IMPLEMENT 5S METHODOLOGY. This lean tool focuses on workplace organization: Sort, Set in order, Shine, Standardize, and Sustain. A clean, organized workspace reduces time spent searching for tools and materials, enhancing safety and efficiency.

STEP 3: DEPLOY ANDON SYSTEMS. Introduce visual management tools like Andon lights or boards. These allow any worker to signal a problem (quality issue, machine fault, material shortage) immediately, triggering a rapid response to prevent small issues from becoming major delays.

STEP 4: ESTABLISH STANDARDIZED WORK. Document the current best practice for each operational task. This ensures consistency, quality, and provides a baseline for future training and continuous improvement efforts. Do not confuse this with stifling innovation; it is about creating a reliable foundation.

STEP 5: ADOPT A CONTINUOUS IMPROVEMENT (KAIZEN) MINDSET. Optimization is not a one-time project. Encourage all employees to suggest small, incremental improvements regularly. Foster a culture where identifying problems is seen as an opportunity, not a failure.

## Common Pitfalls in Supplier Sourcing and Management

A critical component often overlooked is strategic sourcing. Many businesses fall into traps that undermine their manufacturing resilience. One major pitfall is selecting suppliers based solely on unit cost. The cheapest option often carries hidden expenses: longer lead times, inconsistent quality, and poor communication that can halt your entire production line.

Another common mistake is failing to diversify your supplier base. Over-reliance on a single source or geographic region is a massive risk, as recent global events have starkly illustrated. Furthermore, treating suppliers as mere transactional vendors, rather than strategic partners, limits your ability to collaborate on innovation and problem-solving.

From my experience consulting with mid-sized manufacturers, the most successful ones treat their key suppliers as extensions of their own team. They share forecasts, involve them in product design discussions, and work together on cost-reduction initiatives that benefit both parties. This level of integration is a hallmark of a resilient supply chain.

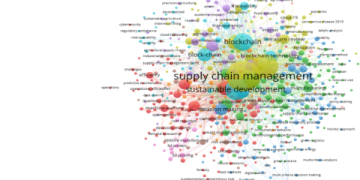

## Building a Resilient and Agile Supply Chain

Resilience is the ability to withstand and recover from disruptions. Agility is the capacity to adapt quickly to changes in demand or supply conditions. Building both requires intentional strategy. It starts with end-to-end visibility. You cannot manage what you cannot see. Implement supply chain visibility software to track materials and components in real time, from your supplier’s dock to your warehouse.

Next, develop scenario planning capabilities. Use data and analytics to model potential disruptions—a port closure, a raw material price spike, a sudden demand surge. Having pre-defined response plans drastically reduces decision-making time during a crisis. Finally, consider nearshoring or regionalizing a portion of your supply base. While not always feasible for all components, bringing some production closer to home can reduce lead times and mitigate geopolitical risks.

## Your Manufacturing Excellence Checklist

To conclude, here is a practical checklist to assess and guide your journey toward manufacturing and supply chain excellence. Use this as a starting point for your strategic planning.

EVALUATE YOUR CURRENT PRODUCTION LINE EFFICIENCY USING VALUE STREAM MAPPING.

AUDIT YOUR QUALITY CONTROL PROCESSES FOR GAPS AT EACH PRODUCTION STAGE.

REVIEW YOUR PRIMARY MANUFACTURING SOFTWARE (ERP/MES) INTEGRATION AND CAPABILITIES.

ANALYZE YOUR TOP 5 SUPPLIER RELATIONSHIPS FOR RISK AND COLLABORATION DEPTH.

IMPLEMENT AT LEAST ONE VISUAL MANAGEMENT TOOL ON THE SHOP FLOOR.

CREATE A SUPPLY CHAIN RISK REGISTER WITH MITIGATION PLANS FOR THE TOP 3 RISKS.

SCHEDULE A CROSS-FUNCTIONAL MEETING TO FOSTER A CONTINUOUS IMPROVEMENT CULTURE.

INVESTIGATE ONE NEW TECHNOLOGY (E.G., IOT SENSORS, AI ANALYTICS) FOR PILOT TESTING.

The principles embodied by Jordan Manufacturing are accessible. They require commitment, strategic investment, and a cultural shift toward continuous improvement. By focusing on integrated technology, lean processes, and partnership-driven sourcing, you can build a manufacturing operation that is not only efficient and high-quality but also resilient and prepared for the future. Start with one item on the checklist and build from there. The path to operational excellence is a journey, not a destination.