# The Ultimate Guide to Supply Chain Shoes: How to Build a Resilient and Profitable Footwear Business

The term SUPPLY CHAIN SHOES might sound like industry jargon, but it represents the very backbone of every successful footwear brand today. It is not just about moving boxes from a factory to a store. It is the complex, interconnected system that dictates your product’s cost, quality, speed to market, and ultimately, your brand’s survival. In an era where consumers demand both sustainability and next-day delivery, mastering your footwear supply chain is no longer optional. It is the definitive competitive edge.

This guide will dissect the modern footwear supply chain, moving beyond theory to provide actionable strategies. We will explore how to build resilience, integrate technology, and create a system that supports growth rather than hindering it.

UNDERSTANDING THE FOOTWEAR SUPPLY CHAIN ECOSYSTEM

At its core, the supply chain for shoes is a global network. It begins with raw material sourcing—leather from Italy, rubber from Vietnam, synthetic fabrics from China—and ends with a satisfied customer unboxing their purchase. The key stages include design and development, material procurement, manufacturing, quality control, logistics, warehousing, and finally, retail and fulfillment.

A fragmented or poorly managed chain at any point causes cascading problems. A delay in polyester delivery pushes back production, which misses a key shipping window, leading to empty shelves during a launch. According to a report by the American Apparel & Footwear Association, over 98% of shoes sold in the U.S. are imported, highlighting the global complexity and logistical challenges inherent in this industry (来源: AAFA).

THE PILLARS OF A MODERN FOOTWEAR SUPPLY CHAIN

Building a robust system rests on four pillars: agility, visibility, collaboration, and sustainability.

Agility is the ability to respond quickly to market changes. This means having flexible manufacturing partners and a logistics network that can switch modes from sea to air freight when necessary.

Visibility is about having a clear, real-time view of your inventory and orders at every stage. You cannot manage what you cannot see.

Collaboration means treating suppliers and logistics partners as strategic allies, not just vendors. Sharing forecasts and data builds trust and efficiency.

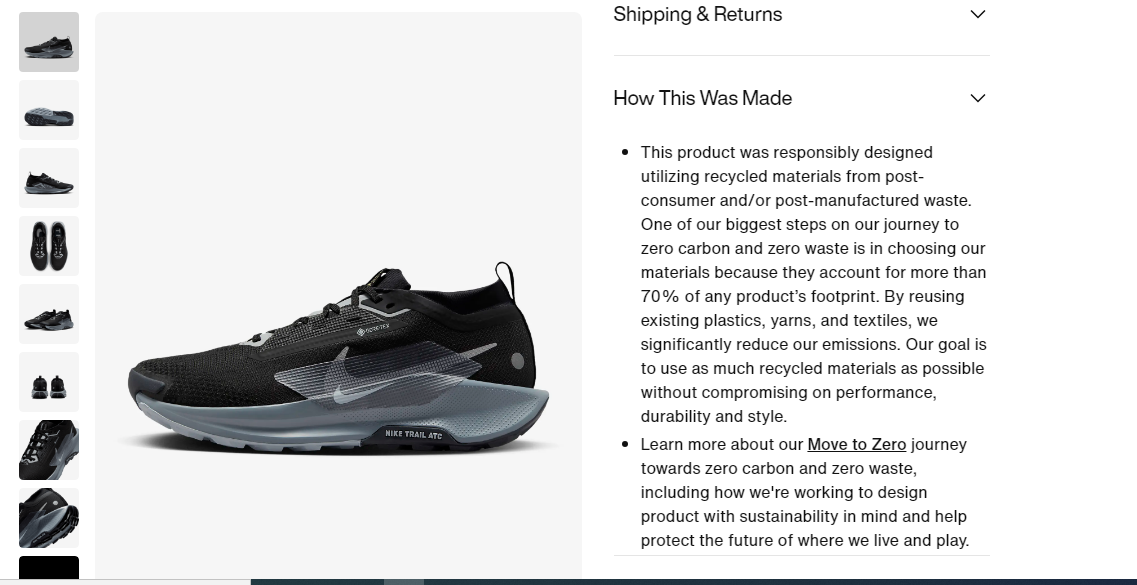

Sustainability is now a business imperative. Consumers are actively seeking brands with ethical sourcing and reduced environmental impact. This pillar influences material choices, factory conditions, and packaging.

TECHNOLOGY: THE NERVOUS SYSTEM OF YOUR OPERATION

Modern supply chain management is powered by software. Relying on spreadsheets and emails is a recipe for errors and delays. Key technologies include:

Product Lifecycle Management (PLM) software streamlines the design and development phase, centralizing materials, components, and specifications.

Enterprise Resource Planning (ERP) systems integrate core business processes, from order management to accounting.

Supply Chain Management (SCM) and Warehouse Management Systems (WMS) provide the visibility and control needed over inventory and logistics.

Here is a comparison of two common approaches brands take when starting their technological integration:

| Feature | Integrated ERP/SCM Suite | Best-of-Breed Point Solutions |

|---|---|---|

| Data Flow | Seamless, single source of truth | Can require complex integrations |

| Implementation | Longer, more complex setup | Faster to deploy for specific needs |

| Cost | Higher initial investment | Lower entry cost, can scale with add-ons |

| Flexibility | Can be less flexible | Highly flexible, choose best tool for each job |

| Best For | Established brands needing deep integration | Growing brands or those with unique process needs |

COMMON PITFALLS AND HOW TO AVOID THEM

Even with the best intentions, brands stumble. Here are critical warnings.

WARNING: DO NOT OVERLOOK THESE SUPPLY CHAIN RISKS

One major pitfall is over-reliance on a single factory or geographic region. Political instability, trade disputes, or a local crisis can halt your entire production. Another is neglecting lead times in planning. The time from design approval to goods on shelf can be 6-9 months. Failing to account for this leads to missed trends. Furthermore, ignoring quality control checks during production, instead of only at the end, results in costly, unfixable errors. Finally, a lack of clear communication protocols with partners creates misunderstandings on specifications, delivery dates, and payment terms.

A FIVE-STEP ACTION PLAN TO OPTIMIZE YOUR FOOTWEAR SUPPLY CHAIN

Ready to take action? Follow this structured approach.

STEP 1: CONDUCT A SUPPLY CHAIN AUDIT. Map your entire current process from start to finish. Identify every partner, every touchpoint, and every data handoff. Look for delays, cost bottlenecks, and communication gaps.

STEP 2: DEFINE KEY PERFORMANCE INDICATORS (KPIs). What does success look like? Measure On-Time Delivery rates, Order Accuracy, Production Lead Time, and Freight Cost per Unit. You cannot improve what you do not measure.

STEP 3: FOSTER STRATEGIC PARTNER RELATIONSHIPS. Move beyond transactional relationships. Visit your key factories and suppliers. Discuss long-term goals, challenges, and explore joint process improvements. According to my experience, the most resilient supply chains are built on partnerships where both parties share risks and rewards.

STEP 4: INVEST IN CORE VISIBILITY TECHNOLOGY. Based on your audit and budget, select a PLM or inventory management system that gives you a real-time view of your production and stock levels. Start with one critical area and expand.

STEP 5: IMPLEMENT DEMAND-DRIVEN PLANNING. Use sales data, trend analysis, and pre-orders to forecast demand more accurately. Share these forecasts with your manufacturing partners to help them plan their raw material purchases and capacity.

THE FUTURE: RESILIENCE AND RESPONSIBILITY

The future of supply chain shoes is transparent and responsive. Technologies like blockchain for material traceability, AI for demand forecasting, and 3D printing for rapid prototyping are moving from concept to reality. The brands that will thrive are those building networks that are not only efficient but also ethical and adaptable. They understand that a strong supply chain is their most valuable asset, directly impacting customer loyalty and brand reputation.

YOUR SUPPLY CHAIN OPTIMIZATION CHECKLIST

Use this list to evaluate and guide your next steps. Ensure your footwear supply chain has the following attributes:

Diversified manufacturing base across at least two geographic regions.

Real-time inventory visibility across all warehouses and in-transit stock.

Established KPIs that are reviewed monthly with your team and key partners.

A digitized workflow for design, development, and purchase orders, eliminating paper and manual entry.

A documented quality control protocol with checkpoints during production, not just at the end.

A sustainability policy covering material sourcing, factory compliance, and packaging.

A contingency plan for logistics disruptions, including alternative shipping routes and freight partners.

Regular, structured communication meetings with your top three suppliers.

An accurate, data-backed demand forecasting process.

A clear understanding of the total landed cost for each product SKU.