# The Ultimate Guide to the Price of Aluminum Zinc in Nigeria: 2024 Analysis & Buying Strategies

Understanding the price of aluminum zinc in Nigeria is crucial for anyone in construction, manufacturing, or large-scale procurement. This material, a coated steel product, is a cornerstone of modern building projects. Its cost is not a single number but a variable influenced by a complex web of factors. This guide provides a deep, actionable analysis to help you navigate the market confidently.

We will break down the current price drivers, compare key suppliers, and offer a step-by-step strategy for securing the best value. Whether you are a project manager, a business owner, or an investor, this information is designed to save you money and prevent costly mistakes.

## What is Aluminum Zinc Coated Steel?

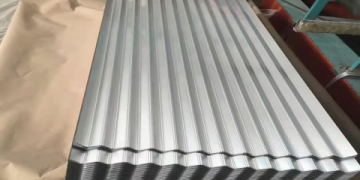

Before diving into costs, it is essential to understand the product. Aluminum zinc coated steel, often known by brand names like ZINCALUME or GALVALUME, is a steel sheet coated with a mixture of approximately 55% aluminum, 43.4% zinc, and 1.6% silicon. This unique alloy coating provides superior corrosion resistance compared to traditional galvanized steel, especially in harsh environments. It offers excellent heat reflectivity and can withstand higher temperatures. In Nigeria, it is widely used for roofing sheets, industrial cladding, and agricultural buildings due to its durability and longevity.

## Key Factors Influencing Aluminum Zinc Sheet Prices in Nigeria

The price of aluminum zinc in Nigeria fluctuates daily. Here are the primary elements that determine the final cost you pay.

INTERNATIONAL RAW MATERIAL COSTS: The global prices of steel, aluminum, and zinc on commodities exchanges like the London Metal Exchange (LME) are the foundational cost drivers. A surge in iron ore or energy costs directly impacts steel production costs, which trickles down.

FOREIGN EXCHANGE RATE: Since most coils are imported, the exchange rate of the Naira to the US Dollar is perhaps the most significant local factor. A weaker Naira instantly makes imported materials more expensive, directly inflating the price of aluminum zinc in Nigeria.

LOGISTICS AND DISTRIBUTION: Costs for shipping, port charges, clearing, and inland transportation from Lagos to other states add substantial margins. Fuel price changes and port congestion can cause sudden price hikes.

GAUGE AND SPECIFICATIONS: Thicker sheets (lower gauge numbers like 0.55mm) cost more than thinner ones (like 0.45mm). The type of coating, color (pre-painted or plain), and profile also affect the price. Always specify your exact requirements when requesting quotes.

MARKET DEMAND AND SEASONALITY: Construction activity often peaks in the dry season (November to April), leading to higher demand and potentially higher prices. Planning purchases during the rainy season slowdown can sometimes yield better deals.

## Current Price Range and Market Overview (2024)

As of mid-2024, the price of aluminum zinc coated sheets in Nigeria is highly dynamic. For standard 0.55mm gauge, plain (non-colored) sheets, prices can range from approximately ₦5,200 to ₦6,800 per square meter, depending heavily on the supplier, location, and immediate forex rates. Pre-painted or colored sheets command a premium.

It is critical to note that these are indicative figures. The Nigerian Bureau of Statistics (NBS) reported a 34.5% year-on-year increase in the cost of imported metals and construction materials as of Q4 2023, highlighting the inflationary pressure in the sector. For the most accurate and current price of aluminum zinc in Nigeria, direct quotations from multiple suppliers are indispensable.

## Major Suppliers and Brand Comparison

The Nigerian market is served by both local rolling mills using imported coils and direct importers of finished sheets. Here is a comparison of the main procurement channels:

| Supplier Type | Key Players/Examples | Pros | Cons |

|---|---|---|---|

| Local Rolling Mills | Mittal Steel, African Steel, etc. | Faster delivery, may support local economy, easier to verify physically. | Prices can be tied to forex volatility, limited gauge variety at times. |

| Direct Importers & Distributors | Numerous large and small companies in Lagos, Port Harcourt, Abuja. | Potential for lower prices on large orders, access to international brands. | Longer lead times, risk of substandard imports, complex logistics. |

| International Brands (via Agents) | BlueScope (ZINCALUME), ArcelorMittal | Guaranteed quality and coating standards, technical support. | Highest price point, may have limited local stock. |

## A 5-Step Guide to Getting the Best Price on Aluminum Zinc Sheets

Follow this actionable guide to make an informed and cost-effective purchase.

STEP 1: DETERMINE YOUR EXACT SPECIFICATIONS. Calculate the total area needed and decide on the gauge, coating type, color, and profile. Wastage of 5-10% should be factored in. Precise specifications prevent suppliers from quoting on inferior or more expensive alternatives.

STEP 2: SOURCE QUOTATIONS FROM DIVERSE SUPPLIERS. Contact at least three different types of suppliers: a local mill, a major distributor, and a direct importer. Ensure all quotes are for the EXACT same specifications and quantity for a fair comparison.

STEP 3: SCRUTINIZE THE QUOTE BEYOND THE UNIT PRICE. Examine delivery costs, payment terms (percentage upfront vs. on delivery), warranty details, and lead time. A slightly higher unit price with better payment terms and reliable delivery may offer more overall value.

STEP 4: VERIFY QUALITY AND AUTHENTICITY. Request for mill test certificates or quality assurance documents, especially for large orders. If possible, visit a supplier’s warehouse to inspect the material’s physical condition and branding.

STEP 5: NEGOTIATE AND TIME YOUR ORDER. Use competing quotes as leverage for negotiation. Consider placing your order during periods of relative Naira stability or lower seasonal demand. Building a long-term relationship with a reliable supplier can lead to better prices over time.

## Common Pitfalls and How to Avoid Them

WARNING: Navigating the aluminum zinc market in Nigeria is fraught with potential missteps that can compromise your project and budget.

THE CHEAPEST QUOTE TRAP: An abnormally low price of aluminum zinc in Nigeria is often a red flag. It may indicate substandard gauge (thinner than stated), inferior coating, or even fraudulent material. Never let price be the sole deciding factor.

IGNORING TOTAL COST OF OWNERSHIP: Focusing only on purchase price ignores durability. Genuine, properly coated aluminum zinc lasts decades longer than fake products, offering far better long-term value despite a higher initial outlay.

VERBAL AGREEMENTS AND VAGUE CONTRACTS: Always insist on a detailed proforma invoice or contract that lists all specifications, prices, delivery schedules, and warranty terms. This document is your primary legal protection.

Based on my experience consulting for construction firms, the most costly errors occur during the supplier vetting stage. We have seen projects delayed by months due to the delivery of off-spec materials that passed a visual inspection but failed in performance.

## Future Outlook and Price Trends

The future price of aluminum zinc in Nigeria will continue to be tied to global commodity cycles and local economic policies. Efforts by the government to boost local steel production could, in the long term, reduce import dependence and stabilize prices. However, infrastructure development projects across the country are likely to keep demand robust. Investing in energy-efficient and durable building materials like quality aluminum zinc remains a wise decision, as it reduces maintenance and replacement costs over the lifespan of a structure.

## Your Aluminum Zinc Procurement Checklist

Use this final checklist before finalizing any purchase. Ensure every item is confirmed.

– Exact material specifications are documented (gauge, coating, color, profile).

– Quotes from at least three different supplier types are obtained.

– Total cost analysis includes delivery, taxes, and handling fees.

– Supplier reputation has been verified through physical visit or client references.

– Quality certification (Mill Test Certificate) has been requested and reviewed.

– A detailed proforma invoice or contract has been issued and reviewed.

– Payment terms and schedule are clear and acceptable.

– Delivery timeline and logistics responsibility are confirmed.

– Warranty and after-sales support details are understood.

– A small sample or previous supply has been inspected for quality.