# The Ultimate Guide to Liberation Day Tariffs and Supply Chain Strategy: 5 Steps to Resilience

Liberation Day tariffs and supply chains are now a critical intersection for global businesses. This specific policy window, often tied to national holidays commemorating independence or historical events, can trigger temporary or permanent changes in trade duties. For supply chain managers, these shifts are not just calendar notes. They represent pivotal moments demanding strategic agility. Understanding this nexus is no longer optional. It is a fundamental component of modern logistics and cost management.

This guide dives deep into the mechanics of Liberation Day tariff announcements and their direct impact on your supply chain. We will move beyond basic definitions. You will get a practical framework for assessment, adaptation, and building long-term resilience against such trade policy fluctuations.

## Understanding Liberation Day Tariffs in a Global Context

Liberation Day tariffs refer to trade duty adjustments announced or enacted around a country’s Liberation Day or similar sovereign holidays. Governments may use these occasions to signal economic policy shifts, protect domestic industries, or respond to international trade pressures. Unlike routine annual adjustments, these changes can be more symbolic and politically charged. They often target specific commodity groups or trading partners.

The link to supply chains is immediate and profound. A sudden tariff increase on imported steel during a manufacturing nation’s Liberation Day can disrupt global automotive and construction supply networks overnight. Conversely, a tariff reduction on electronic components can open new sourcing opportunities. The key is anticipation. Businesses that monitor the political and economic discourse leading up to these dates gain a crucial planning advantage.

## How Tariff Changes Directly Disrupt Your Supply Chain Flow

Tariff adjustments act as a cost shock to your supply chain. The effects ripple through multiple layers. First, there is the direct landed cost increase for imported goods. This squeezes margins and forces difficult decisions: absorb the cost or pass it to customers. Second, sourcing strategies become unstable. A reliable supplier in one country may become uncompetitive overnight, forcing a frantic search for alternatives.

Third, and most complex, is the compliance and administrative burden. New tariff codes, revised rules of origin, and updated customs documentation requirements create bottlenecks. Delays at ports become common as customs authorities implement new directives. According to a 2023 report by the Global Trade Management Institute, 65% of businesses faced significant customs delays following unanticipated tariff announcements. (来源: Global Trade Management Institute Annual Review). This delay translates into inventory shortages, production halts, and missed sales deadlines.

## A Comparative Analysis of Supply Chain Risk Mitigation Tools

Not all strategies for managing tariff risk are equal. Companies often choose between building internal expertise or leveraging external technology. The following table contrasts two primary approaches.

| Approach | Key Features | Pros | Cons |

|---|---|---|---|

| Internal Trade Compliance Team | Dedicated staff, manual monitoring of government gazettes, direct broker relationships. | High degree of control, deep institutional knowledge, direct oversight. | High fixed cost, slower response time, limited scalability, prone to human error. |

| AI-Powered Global Trade Management (GTM) Software | Automated regulatory updates, scenario modeling, integrated customs filing, dashboard analytics. | Real-time alerts, scalable, reduces manual errors, provides data for strategic decisions. | Subscription/licensing costs, requires integration with existing ERP systems. |

The choice depends on your company’s size, trade volume, and complexity. For most organizations dealing with multiple Liberation Day tariffs across different regions, a hybrid model often works best.

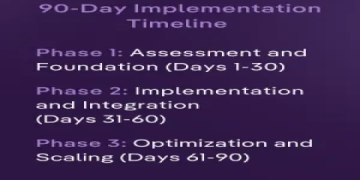

## Your 5-Step Action Plan for Navigating Liberation Day Tariff Announcements

Reactive scrambling is not a strategy. Follow this proactive, step-by-step guide to build a defensive framework.

STEP 1: IDENTIFY AND CALENDAR KEY DATES. Create a master calendar of all Liberation Days and similar national holidays for every country in your supply chain. Mark the 90-day period leading up to each date as a “heightened monitoring window.”

STEP 2: ESTABLISH INTELLIGENCE FEEDS. Subscribe to official government trade publications and leverage services from local chambers of commerce. Assign a team member to monitor political news in those regions for hints of policy changes.

STEP 3: CONDUCT A SUPPLY CHAIN VULNERABILITY ASSESSMENT. Map your entire product bill of materials. Identify which components are sourced from countries with upcoming key dates and note their current tariff classification.

STEP 4: MODEL FINANCIAL SCENARIOS. Work with finance to model the impact of a potential 5%, 10%, and 25% tariff increase on your critical imported items. Understand the exact cost impact per unit and the overall effect on product profitability.

STEP 5: DEVELOP CONTINGENCY SOURCING PLANS. For your most vulnerable items, pre-qualify alternative suppliers in different trade regions. Having these plans on the shelf, even if never used, reduces panic and decision-making time by weeks.

## Common Pitfalls and How to Avoid Them

Even with a plan, companies fall into predictable traps. One major pitfall is focusing solely on direct suppliers. A tariff on raw materials from Country A can cripple your Tier-2 supplier in Country B, who then fails to deliver to your Tier-1 supplier. Always assess risk multi-tier down the chain.

Another mistake is ignoring warehousing and inventory strategy. In my experience consulting with mid-sized manufacturers, we often find they hold either too much or too little buffer stock. The goal is not to hoard inventory but to build strategic buffers for your most tariff-vulnerable, long-lead-time items. This calculated buffer absorbs the shock of initial delays while you activate contingency plans.

## Building a Tariff-Resilient Supply Chain for the Long Term

The ultimate goal is to design a supply chain that is resilient to Liberation Day tariffs and other trade shocks. This goes beyond annual planning. It involves strategic redesign. Consider regionalization—building supplier networks within continental trade blocs like USMCA or the European Union to minimize cross-bloc tariff exposure.

Diversification is another pillar. Avoid single-source dependency for any critical item. Product design also plays a role. Can your engineering team design products with more common, globally available components? This flexibility allows for easier supplier switching. Investing in strong relationships with customs brokers and trade attorneys is also crucial. They provide ground-level intelligence and can expedite solutions during disruptions.

## The Future of Trade Policy and Proactive Adaptation

The era of stable, predictable trade relations is, for now, in the past. Liberation Day tariffs are one symptom of a broader trend toward geopolitical trade policy. Businesses must adopt a mindset of continuous trade intelligence. This means integrating trade news into your regular strategic reviews, not just treating it as a logistics issue.

Technologies like blockchain for provenance tracking and AI for predictive tariff modeling will become standard tools. The businesses that thrive will be those that see changes in supply chain tariffs not as unpredictable disasters, but as manageable variables in a complex global equation. They will have the processes and partners in place to turn a potential crisis into a competitive advantage.

FINAL CHECKLIST FOR MANAGING LIBERATION DAY TARIFFS AND SUPPLY CHAINS

– Map all national holidays for every country in your supply chain.

– Subscribe to official trade bulletin alerts for those countries.

– Classify tariffs for all imported components and raw materials.

– Model financial impacts of potential tariff increases.

– Identify and pre-qualify alternative suppliers for critical items.

– Establish clear communication protocols with logistics partners.

– Review and adjust inventory policy for high-risk items.

– Conduct an annual supply chain vulnerability review.

– Integrate trade policy monitoring into executive reporting.

– Foster cross-department collaboration between procurement, logistics, and finance.

By systematically working through this guide and checklist, you transform the challenge of Liberation Day tariffs and supply chain volatility from a threat into a managed element of your global operations. The path to resilience is built on preparation, not luck.