# The Ultimate Guide to Robotic Process Automation in Supply Chain: 7 Steps to Transform Your Operations

The modern supply chain is a complex web of data, decisions, and dependencies. One missed purchase order, one delayed shipment update, or one inventory discrepancy can ripple into costly delays and customer dissatisfaction. This is where the power of robotic process automation in supply chain management becomes a game-changer. RPA is not about physical robots on the warehouse floor. Instead, it involves software robots, or “bots,” that mimic human actions to execute repetitive, rule-based digital tasks. By deploying these digital workers, companies can achieve unprecedented levels of speed, accuracy, and efficiency across their logistics networks.

This guide will serve as your comprehensive resource. We will explore the transformative applications of RPA, provide a clear implementation roadmap, and highlight the tangible benefits waiting for any organization ready to embrace this technology.

## Understanding RPA and Its Core Mechanism

At its heart, robotic process automation is a technology that allows anyone to configure computer software, or a “robot,” to emulate and integrate the actions of a human interacting within digital systems to execute a business process. These bots can log into applications, move files and folders, copy and paste data, fill in forms, extract structured and semi-structured data from documents, and follow if-then decision trees.

The key value proposition for supply chain operations is that RPA works on top of your existing systems. You do not need to replace your ERP, Warehouse Management System (WMS), or Transportation Management System (TMS). The bots act as a digital layer that connects these disparate systems, automating the flow of information between them without the need for costly and time-consuming custom integrations. This makes robotic process automation in supply chain projects faster to implement and often shows a return on investment in a matter of months.

## Top Applications of RPA in Supply Chain Management

Where exactly can these digital workers make an impact? The applications are vast, but they cluster around data-heavy, repetitive processes. Here are the most impactful use cases.

PROCUREMENT TO PAY: Bots can automate the entire purchase order lifecycle. They can monitor inventory levels and automatically generate POs when thresholds are met, send them to approved suppliers via email, and then match the received invoice against the PO and goods receipt note. This eliminates three-way matching headaches and speeds up vendor payments.

ORDER PROCESSING AND FULFILLMENT: From the moment an order is placed, RPA can take over. Bots can pull orders from e-commerce platforms or EDI feeds, input them into the ERP or OMS, allocate inventory, generate picking lists, and create shipping labels and documentation. This slashes order cycle times from hours to minutes.

SHIPMENT TRACKING AND CUSTOMER COMMUNICATION: Instead of employees manually checking carrier websites, bots can autonomously track shipments across multiple carriers, identify delays, and trigger proactive customer notifications via email or SMS. This dramatically improves customer experience and reduces “where is my order?” inquiry calls.

INVENTORY MANAGEMENT AND RECONCILIATION: Maintaining accurate inventory counts is critical. RPA bots can continuously reconcile data between the WMS, ERP, and point-of-sale systems, flagging discrepancies for human review. They can also automate the generation of cycle count reports and stock replenishment requests.

DATA MIGRATION AND REPORTING: Supply chain reporting often requires manually collating data from multiple spreadsheets and systems. RPA can be scheduled to gather this data, compile it into predefined formats, and distribute reports to stakeholders automatically, ensuring everyone works from a single source of truth.

## RPA vs. Traditional Automation and AI: A Clear Comparison

It is easy to confuse RPA with other forms of automation or with Artificial Intelligence. Understanding the distinction is crucial for setting the right expectations and choosing the right tool for the job. The table below clarifies the key differences.

| Aspect | Robotic Process Automation (RPA) | Traditional IT Automation | Artificial Intelligence (AI) |

|---|---|---|---|

| CORE FUNCTION | Mimics human actions on the user interface. | Integrates systems at the database/API level. | Mimics human cognition (learning, reasoning). |

| REQUIREMENT | Rule-based, structured inputs and processes. | Structured data and predefined workflows. | Can handle unstructured data (emails, images). |

| FLEXIBILITY | High. Easy to configure and reconfigure. | Low. Requires deep coding and is hard to change. | High. Can adapt and improve over time. |

| IMPLEMENTATION | Relatively fast, often weeks. | Slow, can take months to years. | Complex and lengthy, requires data science. |

| COST | Generally lower upfront cost. | High upfront development cost. | Very high investment in data and talent. |

In practice, the most powerful solutions often combine RPA with AI. For instance, an AI-powered cognitive engine can read and interpret a non-standard invoice (unstructured data), and then an RPA bot can execute the data entry and payment process based on that interpretation. This combination is sometimes called Intelligent Process Automation (IPA).

## The Tangible Benefits: Why You Cannot Ignore RPA

The adoption of robotic process automation in supply chain processes delivers measurable returns across several dimensions. A study by Deloitte found that RPA implementations can lead to a 25-50% reduction in process costs and a 50-80% reduction in process execution time. (来源: Deloitte Global RPA Survey). These numbers translate into real-world advantages.

Operational efficiency skyrockets as bots work 24/7 without breaks, processing transactions in a fraction of the time a human would. Accuracy follows suit; by removing manual data entry, error rates in critical processes like order entry and invoice processing can plummet to near zero. This directly enhances compliance and reduces financial losses from mistakes.

From an employee perspective, RPA acts as a force multiplier. It liberates your team from soul-crushing, repetitive tasks, allowing them to focus on higher-value work that requires human judgment, creativity, and strategic thinking, such as supplier relationship management, demand planning, and solving complex logistics problems. This boosts both job satisfaction and overall talent retention.

## A 7-Step Guide to Implementing RPA in Your Supply Chain

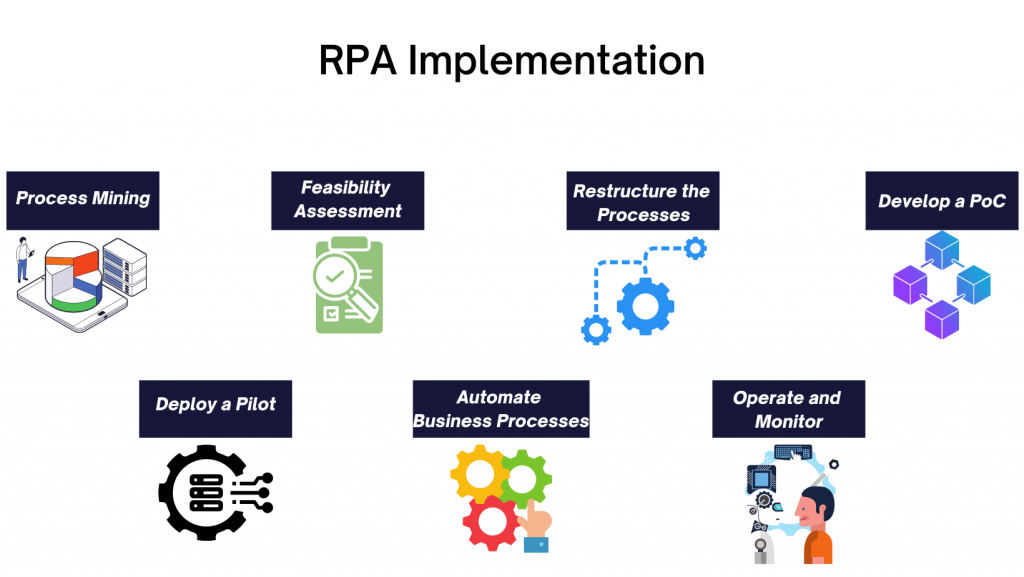

Jumping into an RPA project without a plan is a recipe for failure. Based on my experience leading digital transformation initiatives, a structured approach is non-negotiable. Here is a practical, seven-step guide to ensure your robotic process automation in supply chain project is a success.

STEP 1: IDENTIFY AND PRIORITIZE PROCESSES. Not every process is a good candidate. Look for rules-based, high-volume, stable processes with digital triggers and structured data. Examples include purchase order creation, shipment status updates, and daily sales reports. Avoid processes that change frequently or require complex human judgment.

STEP 2: CONDUCT A DETAILED PROCESS ASSESSMENT. Document the current process in extreme detail. Map every single step, click, and decision point. Identify all applications used, data fields touched, and exceptions that may occur. This document will become the blueprint for your bot.

STEP 3: CALCULATE THE BUSINESS CASE. Quantify the potential ROI. Estimate the current full-time equivalent (FTE) hours spent on the process, the cost of errors, and the opportunity cost of delayed cycles. Compare this against the projected cost of the RPA license, development, and maintenance.

STEP 4: SELECT THE RIGHT RPA PLATFORM AND PARTNER. Evaluate vendors based on your technical environment, scalability needs, and internal expertise. Do you need an attended bot (works with an employee) or an unattended bot (runs autonomously)? A reliable implementation partner can significantly accelerate your first project.

STEP 5: DEVELOP AND TEST THE BOT IN A CONTROLLED ENVIRONMENT. The development team will build the bot using the process blueprint. Rigorous testing is critical. Run the bot through hundreds of test cases, including all the exception paths you documented, to ensure it behaves correctly before it sees live data.

STEP 6: MANAGE THE CHANGE AND TRAIN YOUR TEAM. This step is often underestimated. Communicate transparently with employees whose workflows will change. Emphasize that RPA is a tool to eliminate tedious work, not their jobs. Train them on how to manage, monitor, and handle exceptions for the new digital colleague.

STEP 7: DEPLOY, MONITOR, AND OPTIMIZE. Go live with a phased rollout, perhaps starting with a subset of transactions. Continuously monitor the bot’s performance and error logs. Gather feedback from users and plan for iterative improvements. Remember, implementation is the beginning, not the end.

## Common Pitfalls and How to Avoid Them

WARNING: AVOIDING THESE COMMON RPA MISTAKES IS CRITICAL FOR SUCCESS.

One major pitfall is automating a broken process. RPA will simply do the wrong thing faster. Always streamline and optimize the process first before you automate it. Another critical error is poor exception handling. Bots follow rules blindly. If an unexpected pop-up appears or data is in the wrong format, the bot will fail. Your process blueprint must account for every possible exception, and human oversight for edge cases must be part of the workflow.

Furthermore, treating RPA as a one-time IT project rather than an ongoing program will limit its value. You need a Center of Excellence or a dedicated team to manage the bot portfolio, govern standards, and share best practices across the organization. Finally, neglecting security is a grave risk. Bots have access credentials just like users. Ensure they follow the principle of least privilege and that their credentials are securely managed within a vault.

## The Future: RPA as the Foundation for Intelligent Automation

The journey of robotic process automation in supply chain is just the first step. The future lies in layering more advanced technologies on top of the stable, automated foundation that RPA provides. As mentioned, combining RPA with AI and machine learning creates Intelligent Process Automation. This allows systems to handle unstructured data, make predictive decisions, and continuously learn and improve.

Imagine a system where an AI predicts a potential supplier delay based on news and weather data, an RPA bot automatically triggers an alternative sourcing request, and then another bot updates the production schedule and notifies customers—all without human intervention. This is the autonomous supply chain of the near future, and RPA is the essential bridge to get there.

In conclusion, robotic process automation represents a pragmatic and powerful lever for supply chain transformation. It addresses the chronic pain points of manual data work, unlocking efficiency, resilience, and strategic potential. The question for leaders is no longer if they should explore RPA, but how quickly they can start.

CHECKLIST FOR YOUR FIRST RPA PROJECT:

IDENTIFY a high-volume, rule-based process like order entry or invoice processing.

DOCUMENT every single step, click, data field, and exception in the current process.

CALCULATE a clear ROI based on time savings and error reduction.

SECURE executive sponsorship and communicate the plan to affected teams.

CHOOSE a scalable RPA platform and consider an experienced implementation partner.

DESIGN the bot with comprehensive exception handling and human oversight points.

START with a pilot, monitor performance closely, and plan for scaling.