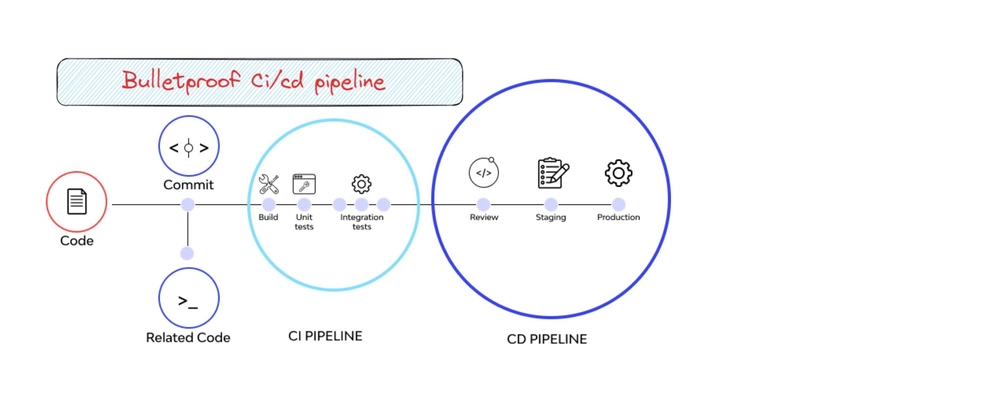

# The Ultimate Guide to Building a Bulletproof Quality Assurance Supply Chain

A single defective component can halt a billion-dollar production line. A contaminated ingredient can trigger a global product recall. In today’s hyper-connected and transparent market, quality is no longer just a final checkpoint. It is a strategic imperative woven into the very fabric of your supply chain. This is where the concept of a Quality Assurance Supply Chain (QASC) becomes non-negotiable. This guide will dissect what a QASC truly is, why it is your most powerful competitive shield, and provide a step-by-step blueprint for building one.

Think of your supply chain as a living organism. The quality assurance supply chain is its immune system. It does not just react to problems at the end. It proactively identifies, prevents, and eliminates risks at every single node: from raw material sourcing and supplier manufacturing to logistics, warehousing, and final delivery. A robust QASC transforms quality from a cost center into a driver of efficiency, brand loyalty, and market dominance.

## What is a Quality Assurance Supply Chain? Beyond Final Inspection

At its core, a Quality Assurance Supply Chain is a holistic, integrated framework. Its primary goal is to ensure that quality standards are consistently met and continuously improved across the entire network of partners and processes. This moves far beyond the traditional “quality control” model of inspecting finished goods.

The modern QASC is built on three pillars: PREVENTION, INTEGRATION, and VISIBILITY. Prevention means designing processes and selecting partners to avoid defects from the start. Integration means embedding quality protocols into procurement, manufacturing, and logistics contracts. Visibility means having real-time data and tracking to monitor quality metrics at every stage. A study by the American Society for Quality found that the cost of a defect found after a product is shipped can be 10 to 100 times more expensive than one caught at the design phase. This stark reality makes a proactive QASC essential.

## The Tangible Benefits: Why Your Business Cannot Afford to Wait

Investing in a quality-focused supply chain is not an expense. It is an investment with a clear and compelling return. The benefits cascade across your entire organization.

First, you achieve significant COST REDUCTION. Preventing defects eliminates scrap, rework, warranty claims, and recall expenses. Second, you gain ENHANCED CUSTOMER SATISFACTION AND LOYALTY. Consistent quality builds trust, reduces returns, and turns customers into advocates. Third, it provides POWERFUL RISK MITIGATION. By understanding and monitoring your suppliers’ processes, you can avoid disruptions caused by quality failures. Fourth, it drives OPERATIONAL EFFICIENCY. Streamlined, right-first-time processes speed up time-to-market and improve overall agility. According to a report by McKinsey & Company, companies with advanced supply chain practices, including robust quality management, achieve a 15-25% improvement in operational efficiency.

## Core Components of a Modern Quality Assurance Framework

Building a bulletproof system requires integrating several key components. These elements work together to create a closed-loop system for quality management.

SUPPLIER QUALITY MANAGEMENT (SQM) is the foundation. This involves rigorous vetting, certification, ongoing audits, and collaborative development with your suppliers. STATISTICAL PROCESS CONTROL (SPC) uses real-time data from production lines to detect variations before they become defects. INTEGRATED QUALITY MANAGEMENT SYSTEMS (QMS) software, like SAP QM or Oracle Quality, centralize all quality data, non-conformance reports, and corrective actions. DIGITAL TRACEABILITY technologies, such as RFID and blockchain, provide an immutable record of a product’s journey, crucial for root cause analysis and recalls. Finally, a CULTURE OF CONTINUOUS IMPROVEMENT, driven by methodologies like Six Sigma or Lean, ensures the system never grows stagnant.

## Technology Showdown: Key Tools for QASC Success

Choosing the right technology stack is critical. The market offers various solutions, each with strengths. Here is a comparison of two primary approaches: Integrated ERP Modules and Best-of-Breed Specialty Software.

| Feature/Capability | Integrated ERP Quality Module (e.g., SAP QM, Oracle Fusion) | Best-of-Breed QMS Software (e.g., ETQ Reliance, Qualio) |

|---|---|---|

| Primary Strength | Seamless data flow with finance, procurement, and production. Single source of truth. | Deep, specialized functionality for quality processes. Often more user-friendly for QA teams. |

| Implementation & Cost | Higher initial cost and complexity, but part of a broader digital transformation. | Typically faster to deploy and can be more cost-effective for mid-size firms. |

| Customization & Flexibility | Can be rigid; customization is complex and expensive. | Usually highly configurable to specific industry or company workflows. |

| Best For | Large enterprises already committed to a core ERP, needing deep operational integration. | Companies where quality is the paramount regulatory or competitive focus, requiring agile tools. |

## A 5-Step Blueprint to Build Your Quality Assurance Supply Chain

Ready to begin? Follow this actionable, step-by-step guide. Based on my experience consulting for manufacturing firms, rushing any of these steps leads to gaps that failures will inevitably find.

STEP 1: MAP AND ASSESS YOUR CURRENT STATE. You cannot improve what you do not measure. Document your entire supply network, including all Tier 1 and critical Tier 2 suppliers. Chart all quality checkpoints and pain points. Conduct a gap analysis against industry standards like ISO 9001:2015.

STEP 2: DEFINE AND COMMUNICATE QUALITY STANDARDS UNEQUIVOCALLY. Develop clear, measurable quality specifications for all materials, components, and finished goods. These must be technically precise and shared with every supplier. Make them a central part of all contracts and service level agreements (SLAs).

STEP 3: IMPLEMENT ROBUST SUPPLIER QUALITY MANAGEMENT. Shift from a policing mindset to a partnership model. Classify suppliers based on risk and performance. Conduct joint process audits, not just product audits. Implement a supplier scorecard system that tracks defects, on-time delivery, and responsiveness.

STEP 4: DEPLOY TECHNOLOGY FOR VISIBILITY AND CONTROL. Select and implement the core technology platforms as discussed. Start with a centralized system for managing non-conformances, corrective actions, and audit findings. Integrate data feeds from key production and logistics partners where possible.

STEP 5: FOSTER A CULTURE OF CONTINUOUS FEEDBACK AND IMPROVEMENT. Establish regular quality review meetings with internal teams and key suppliers. Use data from your systems to drive root cause analysis. Celebrate improvements and share learnings across the network. Make quality everyone’s key performance indicator.

## Common Pitfalls and How to Avoid Them

Even with the best intentions, companies stumble. Being aware of these traps is half the battle.

A MAJOR WARNING: Do not treat your QASC as solely the Quality Department’s responsibility. This is a fatal error. When quality is siloed, it becomes a bottleneck and a blame game. True supply chain quality requires ownership from Procurement (for supplier selection), Operations (for process control), and Logistics (for handling integrity). Leadership must champion this cross-functional integration.

Another frequent mistake is OVER-RELIANCE ON FINAL INSPECTION. Catching a defect at the end is a failure of the system, not a success of inspection. It is the most expensive and least effective way to manage quality. Focus your energy and technology spend on prevention and in-process control. Finally, do not set and forget your standards. Supplier capabilities and material science evolve. Regularly review and update your specifications and testing protocols.

## Your Quality Assurance Supply Chain Launch Checklist

Use this actionable checklist to gauge your readiness and track your progress. A complete QASC transformation is a journey, but each item checked off builds resilience.

– We have mapped our entire multi-tier supply network and identified critical nodes.

– Clear, measurable quality specifications exist for all key purchased items and are contractually binding.

– A formal Supplier Quality Management program with risk-based auditing and scorecards is active.

– A central digital system (QMS) is used to log all non-conformances and track corrective actions.

– Key production processes have defined Statistical Process Control (SPC) limits and monitoring.

– Traceability systems allow us to track any finished product back to its batch and component sources.

– Quality performance metrics are reviewed in cross-functional meetings at least monthly.

– Our organizational culture views quality as a shared responsibility, not a departmental function.

In conclusion, building a resilient quality assurance supply chain is the definitive strategy for thriving in a volatile world. It protects your revenue, your reputation, and your customer relationships. By shifting from detection to prevention, from silos to integration, and from intuition to data, you create not just a supply chain, but a significant and sustainable competitive advantage. The work begins now.