# The Ultimate Guide to Solochain WMS: 5 Key Benefits for Modern Warehouses

Warehouse management is no longer just about stacking boxes. In an era of instant delivery and complex supply chains, the right technology is the difference between profit and loss. This is where a Warehouse Management System, or WMS, becomes non-negotiable. But with so many options, how do you choose? A new contender, Solochain WMS, is gaining attention for its unique approach. This guide will dive deep into what Solochain WMS is, how it works, and why it might be the transformative solution your logistics operation needs.

We will explore its core features, compare it to traditional systems, and provide a clear roadmap for evaluation. By the end, you will have a comprehensive understanding of whether Solochain WMS aligns with your business goals.

## What is Solochain WMS? Defining the Next-Gen Platform

At its core, Solochain WMS is a cloud-based warehouse management software. However, it positions itself beyond basic inventory tracking. The name suggests a focus on a singular, integrated chain—hinting at a streamlined, all-in-one platform. Unlike legacy systems built on decades-old code, modern solutions like Solochain are designed for agility. They typically offer real-time visibility, mobile-first operations, and seamless integration with other business tools like e-commerce platforms and ERP systems.

The global warehouse management system market is projected to reach USD 5.4 billion by 2027, growing at over 15% annually (来源: MarketsandMarkets). This explosive growth is driven by the e-commerce boom and the need for supply chain resilience. Modern WMS solutions are central to this transformation.

## Core Capabilities: How Solochain WMS Operates

A warehouse management system orchestrates the flow of goods from receipt to shipment. Based on available information, Solochain WMS likely encompasses several key functionalities. These form the backbone of its value proposition for inventory control and order fulfillment.

First, it should manage receiving and put-away. This involves scanning incoming items, updating inventory counts instantly, and generating optimal storage locations. Second, it excels at pick, pack, and ship processes. The system can generate efficient pick lists, often using methods like batch picking or zone routing, to minimize worker travel time. Third, robust inventory management is key. This includes cycle counting, lot and serial number tracking, and real-time stock level updates across all sales channels.

A critical feature of any contemporary WMS is its integration capability. Solochain WMS likely connects with online marketplaces (like Amazon, Shopify), shipping carriers (like FedEx, UPS), and accounting software. This creates a single source of truth, eliminating manual data entry and errors.

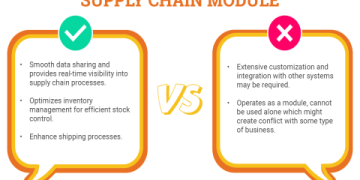

## Solochain WMS vs. Traditional Systems: A Feature Comparison

Choosing a WMS requires a clear comparison. Traditional, on-premise WMS often involves high upfront costs, complex implementations, and rigid structures. Modern, cloud-based platforms like Solochain WMS offer a different model. The following table highlights key differences.

| Feature Aspect | Traditional/On-Premise WMS | Solochain WMS (Cloud-Based Model) |

|---|---|---|

| Deployment & Cost | High upfront license and hardware costs. Ongoing IT maintenance fees. | Typically a subscription-based (SaaS) model with lower initial cost. Hosted in the cloud. |

| Implementation Time | Can take 6 to 12 months or more for full deployment. | Faster deployment, often within weeks, due to standardized cloud infrastructure. |

| Scalability & Updates | Scaling requires new hardware and complex upgrades. Updates are infrequent and costly. | Easily scales with your business. Updates and new features are deployed automatically by the vendor. |

| Accessibility & Mobility | Usually tied to onsite terminals or complex VPN setups. | Accessible from any internet-connected device with a browser. Native mobile apps for floor operations. |

| Integration Approach | Often requires custom, point-to-point coding for each connection. | Built with modern APIs (Application Programming Interfaces) for easier, pre-built connections to common platforms. |

This comparison shows why cloud WMS solutions are becoming the default choice for growing businesses. They offer flexibility and continuous improvement without the heavy IT burden.

## The 5-Step Implementation Guide for Solochain WMS

Implementing a new WMS is a significant project. A structured approach is crucial for success. Here is a practical five-step guide to deploying a system like Solochain WMS.

STEP 1: DEFINE GOALS AND PROCESS MAP. Before touching any software, document your current warehouse processes and identify pain points. Set clear, measurable goals for the implementation, such as “reduce picking errors by 25%” or “cut shipping time by 15%.”

STEP 2: DATA CLEANUP AND MIGRATION. Garbage in, garbage out. Cleanse your existing inventory data—SKU numbers, descriptions, bin locations. This is often the most time-consuming but most critical step. Plan how this data will be migrated into Solochain WMS.

STEP 3: SYSTEM CONFIGURATION AND INTEGRATION. Work with the Solochain team or your implementation partner to configure the software. This includes setting up your warehouse layout, user roles, and workflows. Simultaneously, establish integrations with your e-commerce store, marketplaces, and shipping carriers.

STEP 4: TRAINING AND TESTING. Train your warehouse staff thoroughly using test scenarios. Conduct mock runs of receiving, picking, and shipping to ensure the system works with your real-world operations. Address any issues before going live.

STEP 5: PHASED GO-LIVE AND OPTIMIZATION. Do not flip the switch on everything at once. Consider a phased rollout, starting with one product line or a single shipping zone. Monitor performance closely, gather user feedback, and use the system’s analytics to continuously optimize processes.

COMMON MISTAKE WARNING: A frequent and costly mistake is treating WMS implementation as solely an IT project. In reality, it is a business process transformation. Warehouse managers and floor staff must be involved from the very beginning. Their buy-in and input are essential for configuring a system that works for the people who use it daily. Neglecting this human element is a primary reason for project failure.

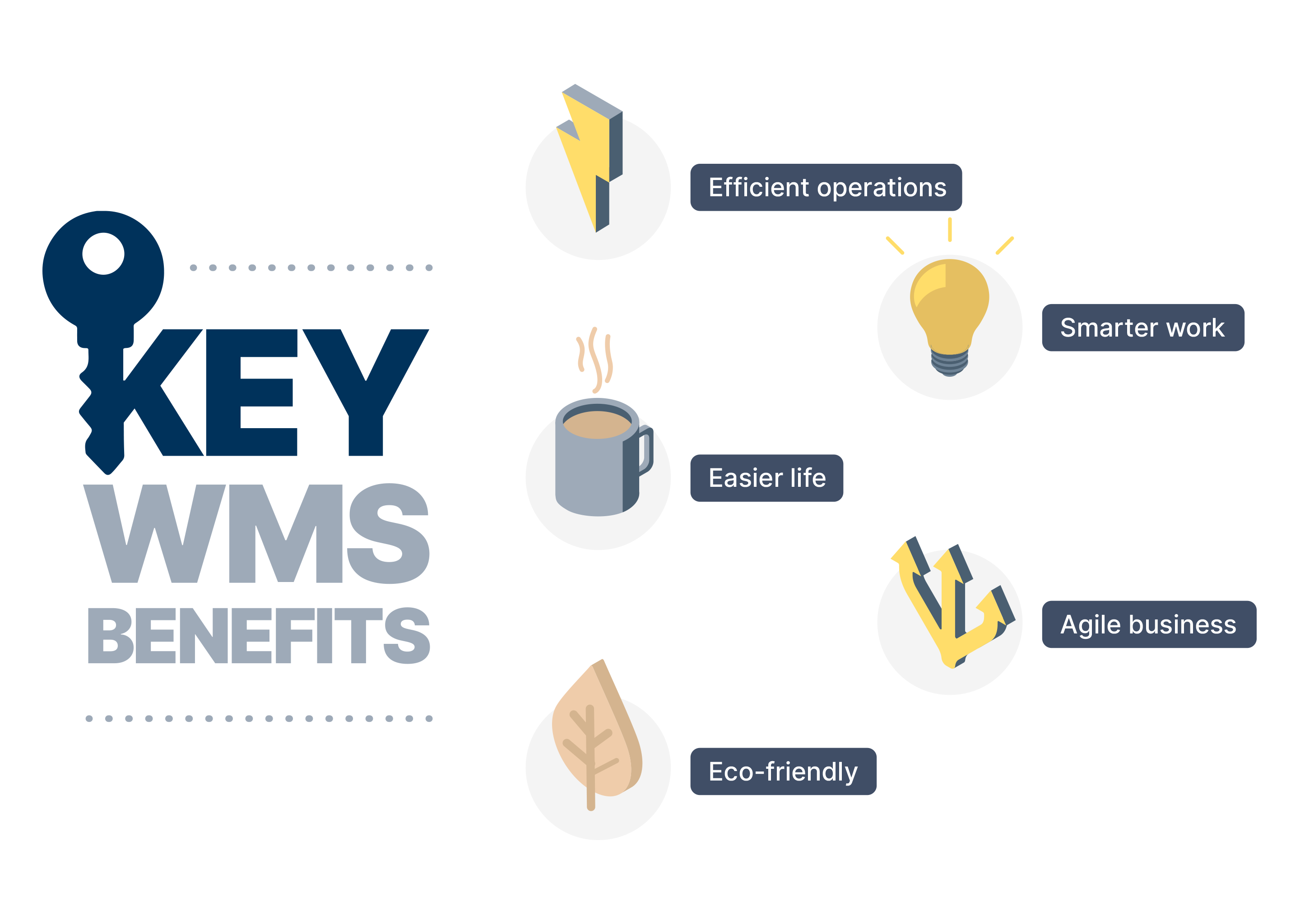

## Real-World Impact: Benefits and Considerations

Based on the architecture of modern cloud WMS, adopting a solution like Solochain WMS can deliver tangible benefits. Increased accuracy and efficiency are primary gains. Barcode scanning at every touchpoint virtually eliminates manual data entry errors. One study found that barcode scanning can reduce picking errors by as much as 80% (来源: Zebra Technologies). This leads to fewer returns and higher customer satisfaction.

Furthermore, real-time visibility is a game-changer. Managers can see exactly what is in stock, what orders are pending, and where bottlenecks are forming, all from a dashboard. This enables proactive decision-making. The scalability benefit is also crucial for growing businesses; you can add users, warehouse locations, or sales channels without a major infrastructure overhaul.

However, it is not without considerations. Our team has seen that success hinges on reliable internet connectivity, as a cloud system is dependent on it. There is also a learning curve for staff accustomed to paper-based or older systems. The long-term subscription cost, while predictable, is an ongoing operational expense versus a one-time capital purchase.

## Is Solochain WMS Right for Your Business? A Practical Checklist

To determine if Solochain WMS is a fit, evaluate your current and future needs. Use this practical checklist to guide your decision-making process.

FINAL EVALUATION CHECKLIST:

– Your business is growing and you anticipate adding more SKUs or sales channels.

– You are experiencing high error rates in picking, packing, or shipping.

– Inventory counts are frequently inaccurate, leading to stockouts or overstock.

– Your team spends excessive time on manual data entry across different systems.

– You lack real-time visibility into warehouse performance and inventory levels.

– You want to reduce dependency on internal IT for system maintenance and upgrades.

– Your warehouse has stable and robust internet connectivity.

– You have the internal resources and commitment to manage a process change and train staff.

If you checked most of these items, a modern WMS like Solochain is likely a strong investment. The next step is to request a live demo, specifically asking to see workflows that match your most challenging operations. Seeing the software in action is the best way to gauge its potential for your unique warehouse environment.