# The HighJump Supply Chain Platform: Your Ultimate Guide to Modern Warehouse and Logistics Management

Modern supply chains are complex beasts. They face constant pressure from rising customer expectations, labor shortages, and unpredictable global events. To survive and thrive, businesses need more than just a basic system to track inventory. They need an intelligent, adaptable platform that connects every link in the chain. This is where the HighJump supply chain platform comes into play. For decades, HighJump, now part of Körber, has been a key player in providing warehouse management and supply chain execution software. But what exactly does it offer today, and how can it transform your operations? This guide dives deep into the capabilities, benefits, and strategic considerations of implementing a HighJump supply chain solution.

We will explore the core components that make up the HighJump ecosystem, examine real-world applications, and provide a clear roadmap for evaluation. Whether you are looking to upgrade an aging system or automate a new facility, understanding the depth of the HighJump supply chain platform is the first critical step.

## Understanding the HighJump Supply Chain Ecosystem

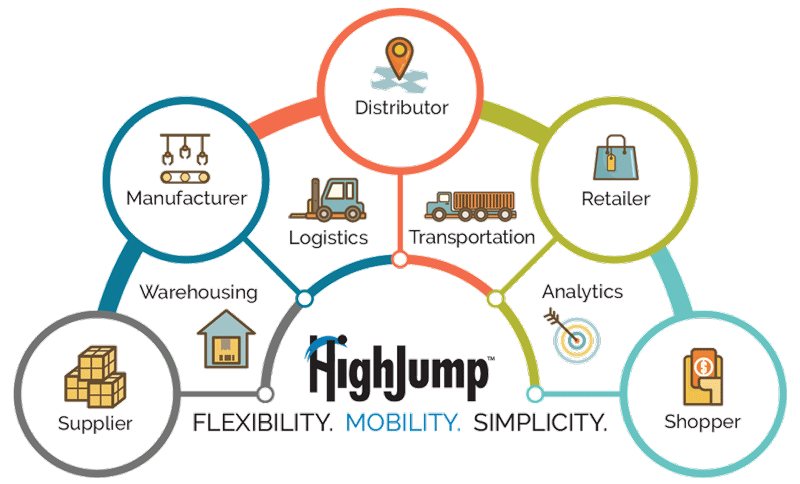

The HighJump supply chain platform is not a single, monolithic application. Instead, it is a suite of interconnected solutions designed to address specific challenges across warehouse management, transportation, and overall supply chain visibility. At its heart, the platform aims to create a connected supply chain where data flows seamlessly from the warehouse floor to the boardroom.

Key components typically include HighJump Warehouse Management System (WMS), which provides core inventory control and labor management. There is also HighJump Transportation Management (TMS) for optimizing shipping costs and carrier selection. Furthermore, the platform often incorporates supply chain visibility tools and business intelligence dashboards. This modular approach allows companies to start with what they need most and expand their capabilities over time. The unifying principle is creating a single source of truth for all logistics data, eliminating silos and enabling smarter, faster decisions.

## Core Capabilities and Benefits of a Modern WMS

A Warehouse Management System is the operational backbone for any distributor or retailer. The HighJump WMS goes beyond simple tracking to drive efficiency and accuracy. Its capabilities directly combat common warehouse pain points.

Primary functions include advanced inventory management with real-time visibility into stock levels across multiple locations. It supports complex picking methodologies like wave, batch, and zone picking to optimize worker travel time. The system also manages receiving and putaway processes, ensuring new stock is logged and stored correctly immediately. Labor management modules track employee productivity and help in fair workload balancing. Furthermore, a robust WMS integrates seamlessly with material handling equipment like conveyors and sortation systems, automating physical workflows. The benefits are tangible: a significant reduction in picking errors, improved inventory accuracy often exceeding 99.9%, and a substantial increase in overall throughput. According to a study by the Warehousing Education and Research Council (WERC), companies using advanced WMS solutions see an average 25% improvement in labor productivity (source: WERC Benchmarking Reports).

## HighJump vs. Competing Supply Chain Platforms

Choosing the right supply chain software is a major decision. To help frame your evaluation, here is a comparison of HighJump (Körber) against another major player, Blue Yonder (formerly JDA), focusing on key decision factors.

| Feature / Aspect | HighJump (Körber) | Blue Yonder |

|---|---|---|

| Primary Deployment Focus | Strong offerings in both cloud-based (SaaS) and on-premise deployments, with flexibility. | Historically strong in on-premise, with a major push toward cloud/SaaS in recent years. |

| Industry Specialization | Known for deep strength in manufacturing, distribution, and third-party logistics (3PL). | Extremely broad and deep across retail, manufacturing, and logistics, with a strong AI/ML focus. |

| Implementation & Customization | Often praised for configurable solutions that can adapt to unique workflows without heavy coding. | Powerful but can be complex; implementations may be longer and require significant partner involvement. |

| Technology & Innovation | Focuses on practical automation, IoT integration, and user-friendly interfaces for warehouse staff. | Heavy investment in artificial intelligence and predictive analytics for autonomous supply chains. |

| Overall Cost Profile | Can be positioned as a high-value solution, potentially with a lower total cost of ownership for mid-market. | Generally positioned at the enterprise premium tier, with licensing and services reflecting that. |

This table provides a snapshot. The best choice depends entirely on your company size, industry, specific process complexity, and budget.

## A Step-by-Step Guide to Evaluating HighJump for Your Business

Implementing a new supply chain platform is a strategic project. Rushing the evaluation can lead to costly mistakes. Follow this structured, five-step process to make an informed decision.

STEP 1: INTERNAL PROCESS AUDIT. Before looking at any software, map your current warehouse and logistics processes in detail. Identify your top three pain points (e.g., slow shipping, high error rates, lack of visibility). Document your growth goals and any planned changes to your product lines or customer service promises.

STEP 2: DEFINE REQUIREMENTS AND BUDGET. Translate your audit findings into a formal list of software requirements. Separate “must-have” features from “nice-to-have.” Concurrently, establish a realistic budget range, including software licensing, implementation services, hardware, and ongoing support.

STEP 3: REQUEST DEMONSTRATIONS AND REFERENCES. Contact HighJump and other shortlisted vendors. Do not accept generic demos. Provide a specific, challenging scenario from your own operations (e.g., handling a peak-season rush or managing a complex returns process) and ask them to demonstrate how their platform would handle it. Crucially, ask for and contact customer references in your industry.

STEP 4: ASSESS TOTAL COST AND TIMELINE. Review the detailed proposals. Look beyond the initial license fee. Understand all implementation costs, annual maintenance fees, and potential costs for future upgrades or adding users. Get a clear project timeline from each vendor.

STEP 5: EVALUATE THE PARTNER, NOT JUST THE PRODUCT. You are not just buying software; you are entering a partnership. Evaluate the vendor’s and implementation partner’s expertise, support structure, and cultural fit. Ensure they have a proven track record of successful go-lives for companies like yours.

## Common Pitfalls to Avoid During Implementation

Even with the best software, success is not guaranteed. Implementation is where projects stumble. Based on my experience consulting with logistics teams, the most frequent mistake is treating the implementation as a purely IT-driven project. The warehouse management system will change how every floor worker does their job. If operations leadership and frontline supervisors are not deeply involved from day one, user adoption will fail.

Another major pitfall is attempting to replicate every quirk of your old, potentially inefficient process within the new system. The goal of a modern platform like HighJump is to enable best practices. Use the implementation as an opportunity to streamline and improve processes, not just automate bad ones. Finally, underestimating the importance of data cleanliness is a project killer. Garbage in, garbage out. Allocate sufficient time and resources to cleanse your item master, customer data, and inventory records before migration. Skipping this step ensures the new system starts with the same problems as the old one.

## The Future of Supply Chain Technology with Platforms Like HighJump

The trajectory for supply chain technology is clear: greater connectivity, intelligence, and automation. Platforms like HighJump are increasingly integrating Internet of Things (IoT) sensors, which provide real-time data on equipment health, environmental conditions, and asset location. Artificial intelligence and machine learning are moving from buzzwords to practical tools for predicting demand, optimizing inventory placement, and dynamically rerouting shipments.

Perhaps the most significant shift is toward what Körber calls the “connected supply chain.” This vision involves breaking down barriers between WMS, TMS, and other enterprise systems to create a responsive, self-optimizing network. For businesses, this means moving from reactive problem-solving to proactive exception management. The system can alert you to a potential stock-out or a delayed carrier before it impacts a customer, allowing you to take corrective action automatically. A report by Gartner highlights that by 2026, over 75% of commercial supply chain management application vendors will deliver embedded advanced analytics, AI, and data science (source: Gartner, “Predicts 2023: Supply Chain Technology”). Platforms evolving in this direction are positioning their users for a more resilient future.

In conclusion, the HighJump supply chain platform represents a powerful toolset for businesses seeking to modernize their logistics. Its strength lies in a practical, configurable approach to warehouse and transportation management. By thoroughly understanding your needs, carefully evaluating the solution, and navigating implementation with best practices in mind, you can unlock significant gains in efficiency, accuracy, and customer satisfaction. The journey to a smarter supply chain starts with informed strategy.

CHECKLIST FOR EVALUATING A HIGHJUMP SUPPLY CHAIN SOLUTION:

– Conducted a full internal process and pain-point audit.

– Defined and documented clear must-have software requirements.

– Established a comprehensive project budget including all costs.

– Scheduled and attended scenario-specific software demonstrations.

– Received and contacted customer references in a similar industry.

– Evaluated the total cost of ownership over a 5-year period.

– Assessed the implementation partner’s experience and cultural fit.

– Secured commitment from operational leadership (not just IT) for the project.

– Planned for data cleansing and migration as a key project phase.

– Understood the roadmap for future innovation like IoT and AI within the platform.