# The Ultimate Guide to Supply Chain Management SaaS: 5 Steps to Modernize Your Operations

The global supply chain is no longer a linear, predictable beast. It is a dynamic, interconnected web where a delay in one port can ripple into a stockout across continents. Managing this complexity with spreadsheets and legacy software is like navigating a storm with a paper map. This is where supply chain management SaaS becomes not just a tool, but a strategic imperative. Cloud-based software for supply chain management delivers the agility, visibility, and intelligence needed to thrive in modern commerce.

This guide will break down everything you need to know. We will explore what makes this technology transformative, how to select the right platform, and provide a concrete action plan for implementation.

UNDERSTANDING THE CORE OF SUPPLY CHAIN MANAGEMENT SAAS

At its heart, supply chain management SaaS is a suite of applications delivered over the internet that manages the flow of goods, data, and finances from origin to consumption. Unlike traditional on-premise software, it is hosted in the cloud. Users access it via a web browser, paying a subscription fee. This model offers several foundational advantages.

First is scalability. As your business grows, your software can grow with it instantly, without major hardware investments. Second is accessibility. Key stakeholders from procurement to logistics to the C-suite can access real-time data from anywhere. Third is continuous innovation. The vendor handles all updates, ensuring you always have the latest features and security patches without disruptive upgrades.

KEY CAPABILITIES OF A MODERN SAAS PLATFORM

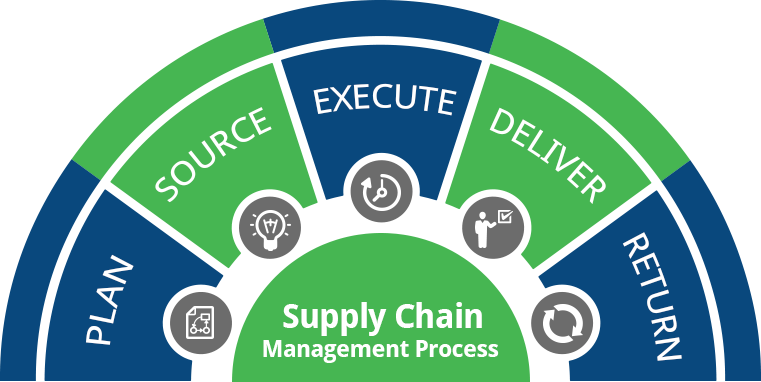

A robust supply chain management SaaS platform integrates several critical functions. Demand forecasting uses AI and machine learning to predict customer needs more accurately. Inventory optimization ensures you have the right stock in the right place at the right time, minimizing carrying costs and stockouts. Order management streamlines the process from customer click to shipment. Logistics and warehouse management coordinate transportation and storage efficiently. Finally, supplier relationship management provides visibility into vendor performance and risk.

The magic happens when these modules are unified on a single data platform. This breaks down information silos. For example, a demand forecast can automatically trigger a purchase order to a supplier, which then updates the warehouse management system to prepare for incoming stock. This end-to-end connectivity is the true value proposition.

WHY BUSINESSES ARE MIGRATING TO THE CLOUD: THE DATA DOES NOT LIE

The shift is undeniable. According to Gartner, by 2026, over 60% of newly purchased supply chain planning application software will be SaaS-based, up from approximately 45% in 2021. (来源: Gartner). The drivers are clear. A study by McKinsey found companies with highly digitized supply chains can expect efficiency gains of over 50% and a revenue increase of up to 20%. (来源: McKinsey & Company).

From my experience consulting with mid-sized manufacturers, the catalyst for change is often a specific pain point. One client was losing major contracts due to inconsistent on-time delivery. Their legacy systems could not provide accurate shipment ETAs. After implementing a supply chain visibility SaaS, they improved their delivery reliability by 35% within a year, simply because everyone was looking at the same, real-time data.

CHOOSING THE RIGHT SUPPLY CHAIN MANAGEMENT SAAS: A COMPARISON

Not all platforms are created equal. Your choice depends on company size, industry, and specific challenges. Here is a comparison of two common approaches: best-of-suite vs. best-of-breed.

| Feature | Best-of-Suite (e.g., SAP S/4HANA Cloud, Oracle Fusion) | Best-of-Breed (e.g., Kinaxis, E2open) |

|---|---|---|

| Core Philosophy | Single, integrated platform covering ERP, finance, HR, and supply chain. | Specialized, deep functionality for specific supply chain processes. |

| Integration | Native integration between modules. Seamless data flow. | Requires APIs and middleware to connect with other business systems. |

| Flexibility & Depth | Broad functionality, but may lack depth in advanced planning. | Highly specialized tools with advanced algorithms (e.g., for concurrent planning). |

| Implementation | Can be complex and lengthy due to scope. | Typically faster to deploy for the specific function. |

| Ideal For | Large enterprises seeking a single source of truth across the entire business. | Companies where supply chain is a primary competitive advantage. |

COMMON PITFALLS TO AVOID DURING SELECTION

WARNING: A frequent and costly mistake is selecting software based on a feature checklist alone. Technology enables processes; it does not define them. A platform with every bell and whistle is useless if your team cannot or will not adopt it. Another major pitfall is underestimating the importance of data quality. A supply chain management SaaS platform runs on data. Feeding it inaccurate or inconsistent information on inventory, lead times, or demand will result in poor recommendations, a phenomenon often called “garbage in, garbage out.” Always start with a data audit.

YOUR 5-STEP ROADMAP TO SUCCESSFUL IMPLEMENTATION

Transitioning to a new supply chain management SaaS is a business transformation project. Follow this structured approach.

STEP 1: DEFINE YOUR STRATEGIC OBJECTIVES.

Begin with the “why.” Are you aiming to reduce inventory costs by 15%? Improve perfect order rate by 20%? Shorten cash-to-cash cycle time? Establish 3-5 clear, measurable goals. This will guide every subsequent decision and provide a benchmark for success.

STEP 2: MAP AND OPTIMIZE KEY PROCESSES.

Do not automate broken processes. Document your current “as-is” workflows for order fulfillment, procurement, and demand planning. Identify bottlenecks, redundancies, and manual handoffs. Design a simplified, improved “to-be” process that the new software will support.

STEP 3: SELECT THE VENDOR WITH A FOCUSED PILOT.

Use your objectives and process maps to create a vendor shortlist. Go beyond sales demos. Request a proof-of-concept or pilot project using your own data for a specific process, like forecasting for one product line. This reveals real-world usability and fit.

STEP 4: PLAN FOR DATA MIGRATION AND INTEGRATION.

This is the most technical and critical phase. Cleanse your historical data. Define how the new SaaS platform will connect with your existing ERP, e-commerce store, and warehouse systems. A robust integration plan prevents future data silos.

STEP 5: EXECUTE A PHASED ROLLOUT WITH ROBUST TRAINING.

Do not go live everywhere at once. Start with one region, one warehouse, or one product category. This limits risk. Concurrently, run immersive training sessions tailored to different user roles (planners, buyers, warehouse staff). Appoint internal “champions” to drive adoption.

THE FUTURE IS INTELLIGENT AND CONNECTED

Looking ahead, the evolution of supply chain management SaaS is toward greater autonomy and interconnection. We are seeing the rise of control towers that provide a holistic, predictive view of the entire network. Internet of Things (IoT) sensors will feed real-time condition data (like temperature or shock) directly into the platform. More interestingly, generative AI will move beyond analysis to proactive suggestion and automated resolution of common disruptions.

The journey to a modern, resilient supply chain starts with a single step: evaluating your current capabilities against the power of a unified, cloud-based platform. By following a disciplined approach, you can turn your supply chain from a cost center into a formidable competitive weapon.

IMPLEMENTATION CHECKLIST

– Define and document 3-5 measurable business objectives for the project.

– Conduct a full audit and cleansing of master data (SKUs, suppliers, lead times).

– Map current “as-is” processes for at least two core supply chain functions.

– Design desired “to-be” processes that leverage SaaS capabilities.

– Shortlist vendors based on strategic fit, not just features.

– Secure a pilot or proof-of-concept using your company’s data.

– Develop a detailed data migration and system integration plan.

– Create role-specific training materials and identify internal power users.

– Choose a phased rollout strategy, starting with a low-risk area.

– Establish KPIs and a review cycle to measure post-implementation success.